Machine control and safety specialist Prolec has developed a total machine control system, called Prolec Machine Engine (PME). Rather than having separate controllers for safety applications such as weighing, stability and safe load indication, plus additional controllers for digging applications and data capture, the PME aims to combine all of these features in a single module. Suitable for all makes of machines and capable of working with cranes, telehandlers, excavators, backhoe loaders, concrete, fork l

January 6, 2017

Read time: 1 min

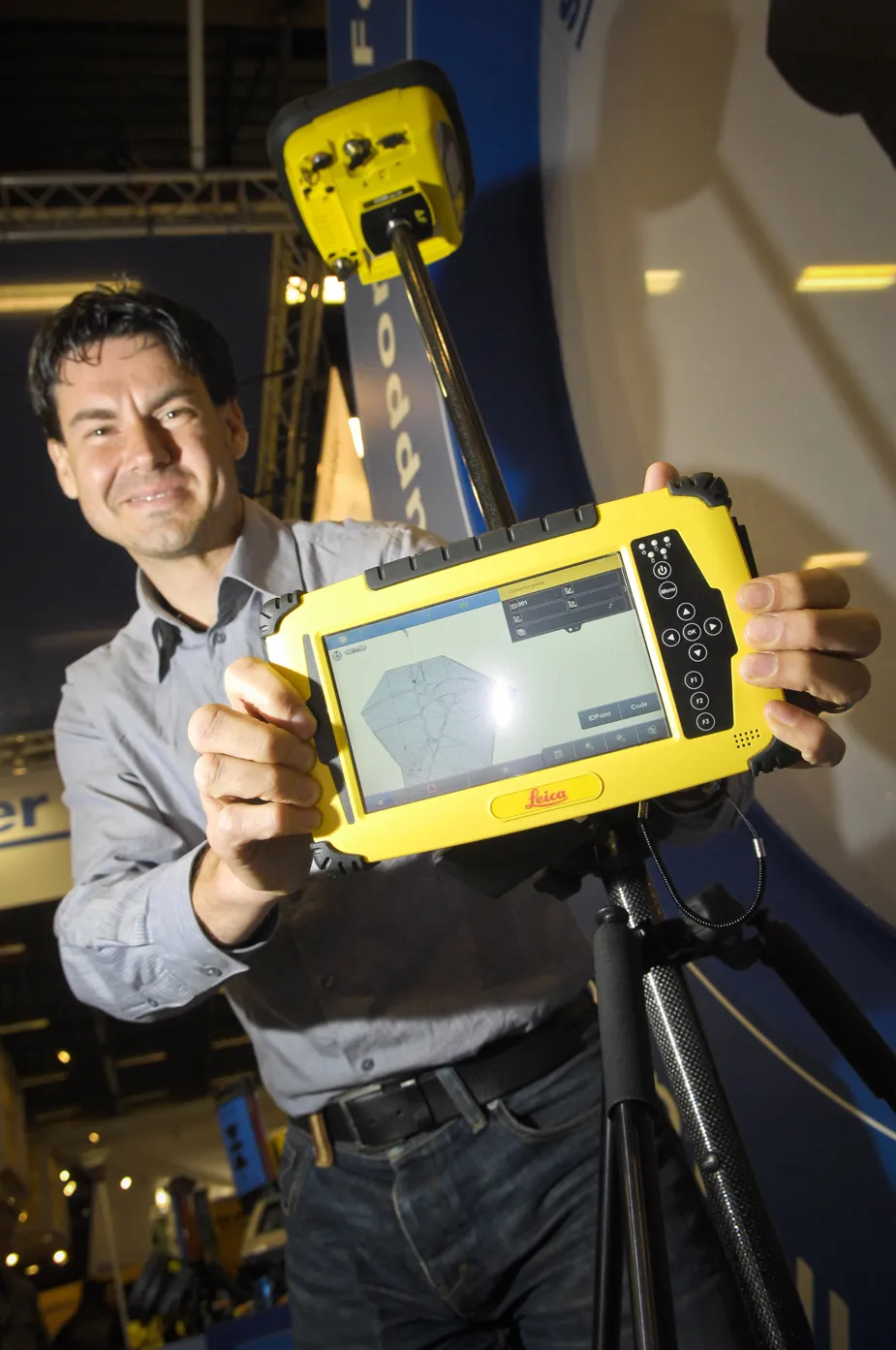

RSSMachine control and safety specialist 309 Prolec has developed a total machine control system, called Prolec Machine Engine (PME).

Rather than having separate controllers for safety applications such as weighing, stability and safe load indication, plus additional controllers for digging applications and data capture, the PME aims to combine all of these features in a single module.

Suitable for all makes of machines and capable of working with cranes, telehandlers, excavators, backhoe loaders, concrete, fork lifts and many other types of machine, PME conforms to the Machinery Directive EN15849.

Using Prolec’s existing sensors, the system measures the various parameters of the machine, including depth monitoring, reach and overturn control. In the future PME will also function with both 2D and 3D machine guidance and control systems, providing a completely integrated machine control solution.

View more stories

View more videos

Rather than having separate controllers for safety applications such as weighing, stability and safe load indication, plus additional controllers for digging applications and data capture, the PME aims to combine all of these features in a single module.

Suitable for all makes of machines and capable of working with cranes, telehandlers, excavators, backhoe loaders, concrete, fork lifts and many other types of machine, PME conforms to the Machinery Directive EN15849.

Using Prolec’s existing sensors, the system measures the various parameters of the machine, including depth monitoring, reach and overturn control. In the future PME will also function with both 2D and 3D machine guidance and control systems, providing a completely integrated machine control solution.

Hall: 5A Stand: G096

RSSView more stories

View more videos