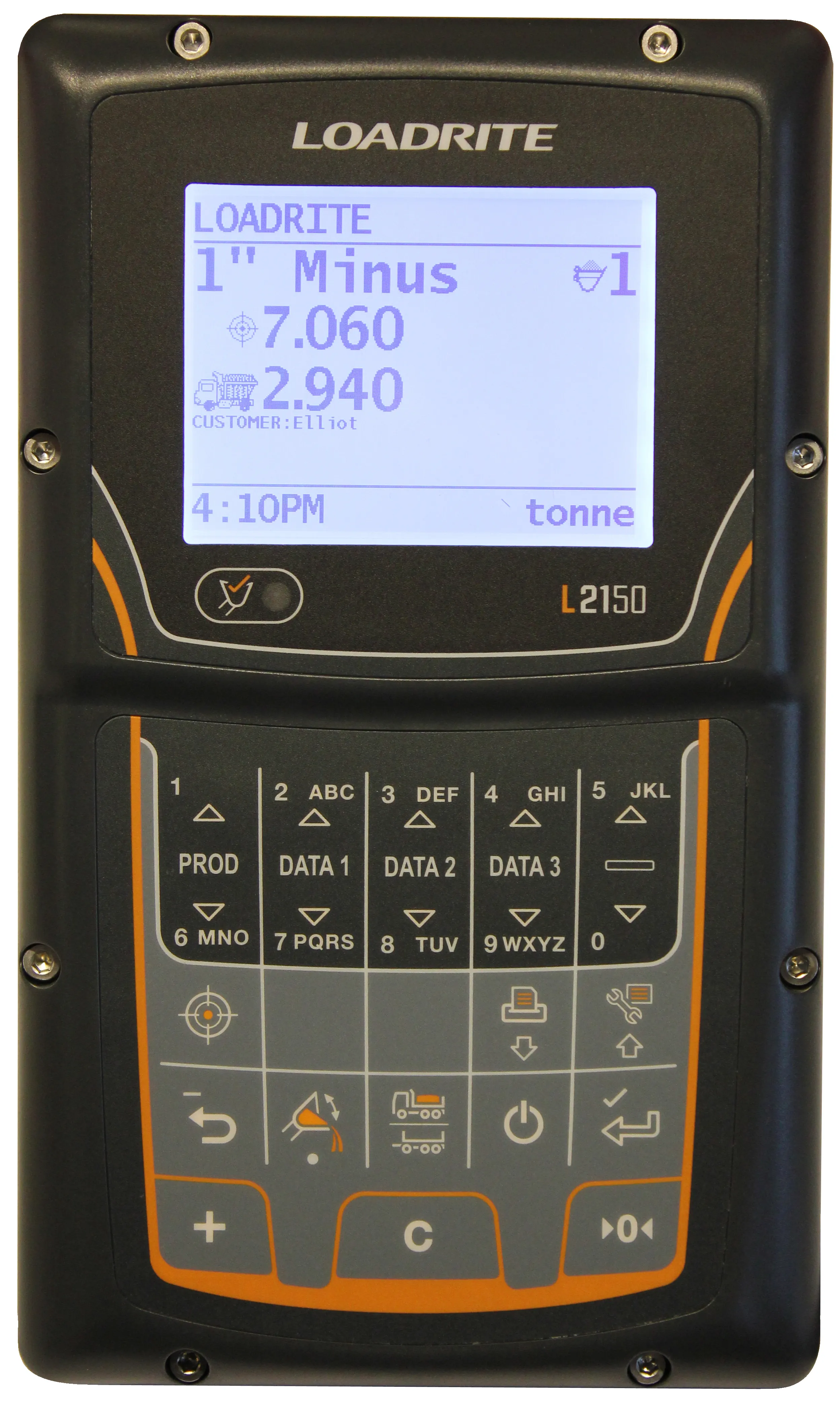

Loadrite global marketing communications manager Simon Rush says the New Zealand firm’s on-board weighing systems for construction machines have been designed with operators in mind. “They take raw data and turn it into something really easy to understand,” said Rush. “Operators are only using one button 90% of the time, which means they are more likely to take up using them.” The Loadrite X-Weigh 2350, being exhibited at INTERMAT, can track overall tonnes and tonnes per hour throughout a construction proje

April 18, 2012

Read time: 2 mins

RSS5004 Loadrite global marketing communications manager Simon Rush says the New Zealand firm’s on-board weighing systems for construction machines have been designed with operators in mind.

“They take raw data and turn it into something really easy to understand,” said Rush.

“Operators are only using one button 90% of the time, which means they are more likely to take up using them.”

The Loadrite X-Weigh 2350, being exhibited at INTERMAT, can track overall tonnes and tonnes per hour throughout a construction project, ensuring that each truckload moved on site is accurately loaded and recorded.

“The systems allow machine operators to have visibility of what’s happening on site and managers can receive an email breakdown of what’s happening on one site or across a number of sites,” said Rush.

“These systems are a total solution for a quarry, a mine or demolition.”

The company is also showcasing at INTERMAT a number of its on-board weighing systems, including its L-Series 2180 system for wheel loaders; and its C-Series conveyor belt scale.

“Business is pretty good just now,” said Rush. “We are dominant in Australasia, doing well in North America and China is a good market for us. We’ve just established a wholly-owned firm entity in China under the name Loadrite China.”

View more stories

View more videos

“They take raw data and turn it into something really easy to understand,” said Rush.

“Operators are only using one button 90% of the time, which means they are more likely to take up using them.”

The Loadrite X-Weigh 2350, being exhibited at INTERMAT, can track overall tonnes and tonnes per hour throughout a construction project, ensuring that each truckload moved on site is accurately loaded and recorded.

“The systems allow machine operators to have visibility of what’s happening on site and managers can receive an email breakdown of what’s happening on one site or across a number of sites,” said Rush.

“These systems are a total solution for a quarry, a mine or demolition.”

The company is also showcasing at INTERMAT a number of its on-board weighing systems, including its L-Series 2180 system for wheel loaders; and its C-Series conveyor belt scale.

“Business is pretty good just now,” said Rush. “We are dominant in Australasia, doing well in North America and China is a good market for us. We’ve just established a wholly-owned firm entity in China under the name Loadrite China.”

Hall: 5A Stand: G078

RSSView more stories

View more videos