The firm’s IMP 20 processor now benefits from a new design that allows the user to change the jaw more quickly than before. The company offers the unit with different jaws that allow it to be used in various breaker, pulveriser and shear configurations while mounted on the same carrier. This versatile unit has three different sets of jaws, allowing it to be used for demolition, cutting and pulverising.

It has the company’s proven, 360° hydraulic rotation system, while its jaws are reversible for extra life. The unit has interchangeable teeth for its pulveriser jaws, while in the shear configuration the unit offers the same geometry and piercing system as the firm’s ISS shears. The single axis of rotation is said to make maintenance easier, as well as speeding and jaw set replacement.

The use of HARDOX steel is said to extend life and eliminate flexing, while other features helping boost working life include the greasing system, protection valve, steel shafts to protect the pistons and robust overall structure.

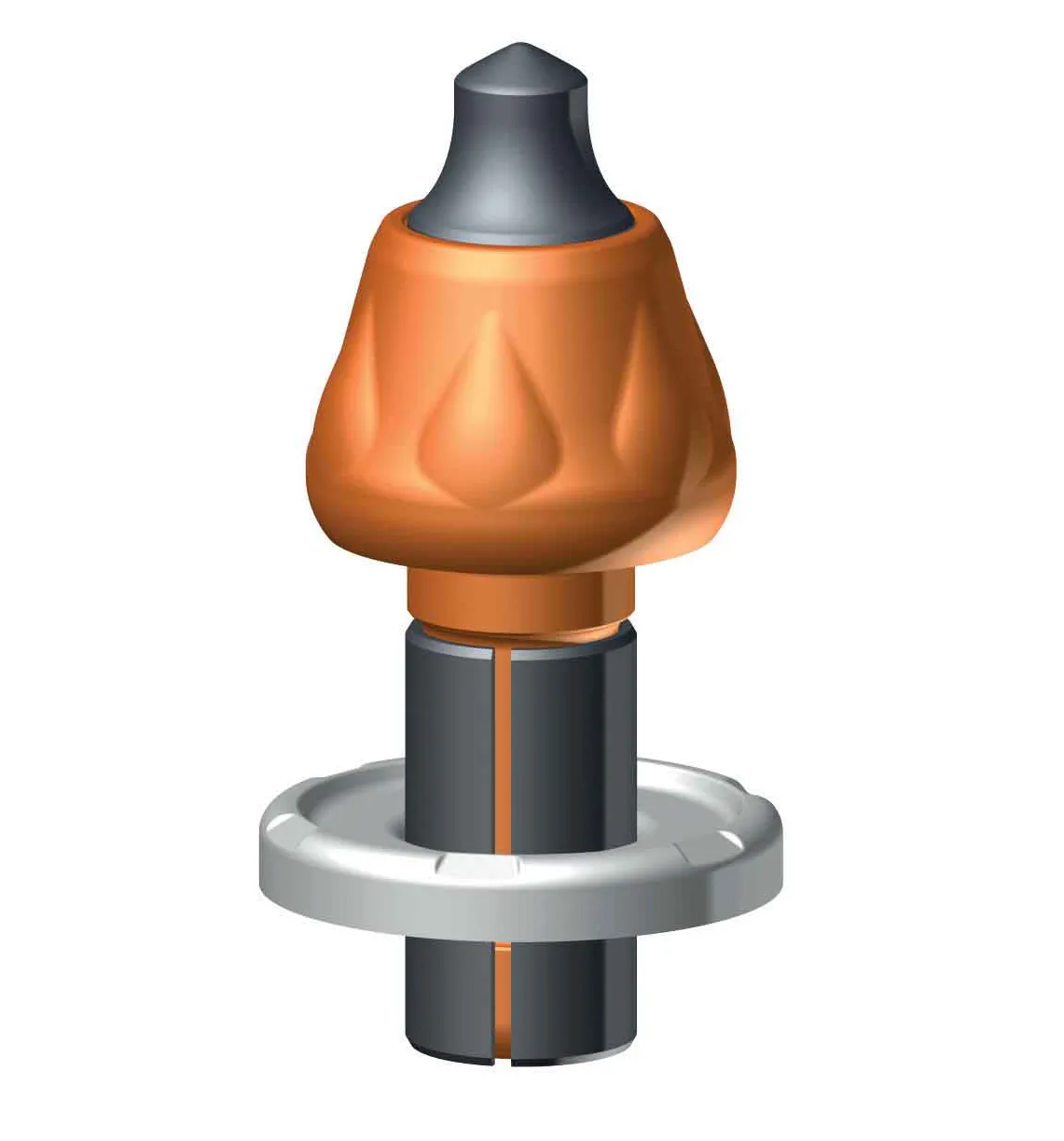

High power is claimed for the IRP 5X pulveriser, which also features HARDOX steel in its construction to optimise stiffness and wear life. The hydraulics are made more efficient due to a regeneration valve that speeds jaw closing when there is no load. The proven, durable rotation system is used and the unit can cope with high wear conditions, sharing working features with the other models in the range. The IRP 5X is designed for carriers from 5-12tonnes and weighs 570kg. As with the firm’s other pulverisers, the unit offers adjustment of the distance between the cutters located inside the jaws and interchangeable teeth on the mobile jaw.

Indeco is now offering its HP 350 breaker with a low pressure water spray system to reduce dust emissions. This 230kg breaker suits carriers from 1.7-6.5tonnes and delivers a blow rate of 540-1,540bpm with its 56mm diameter steel.