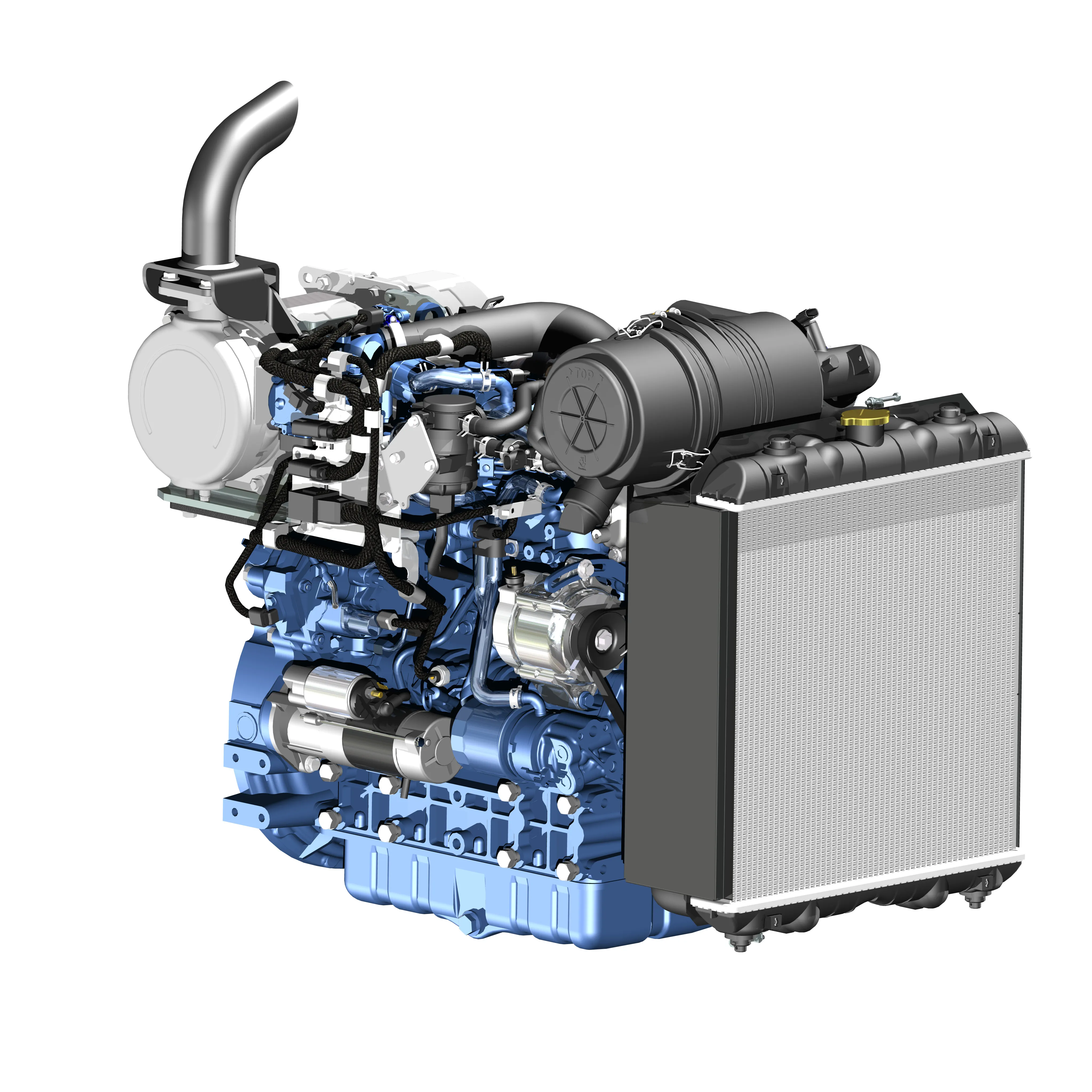

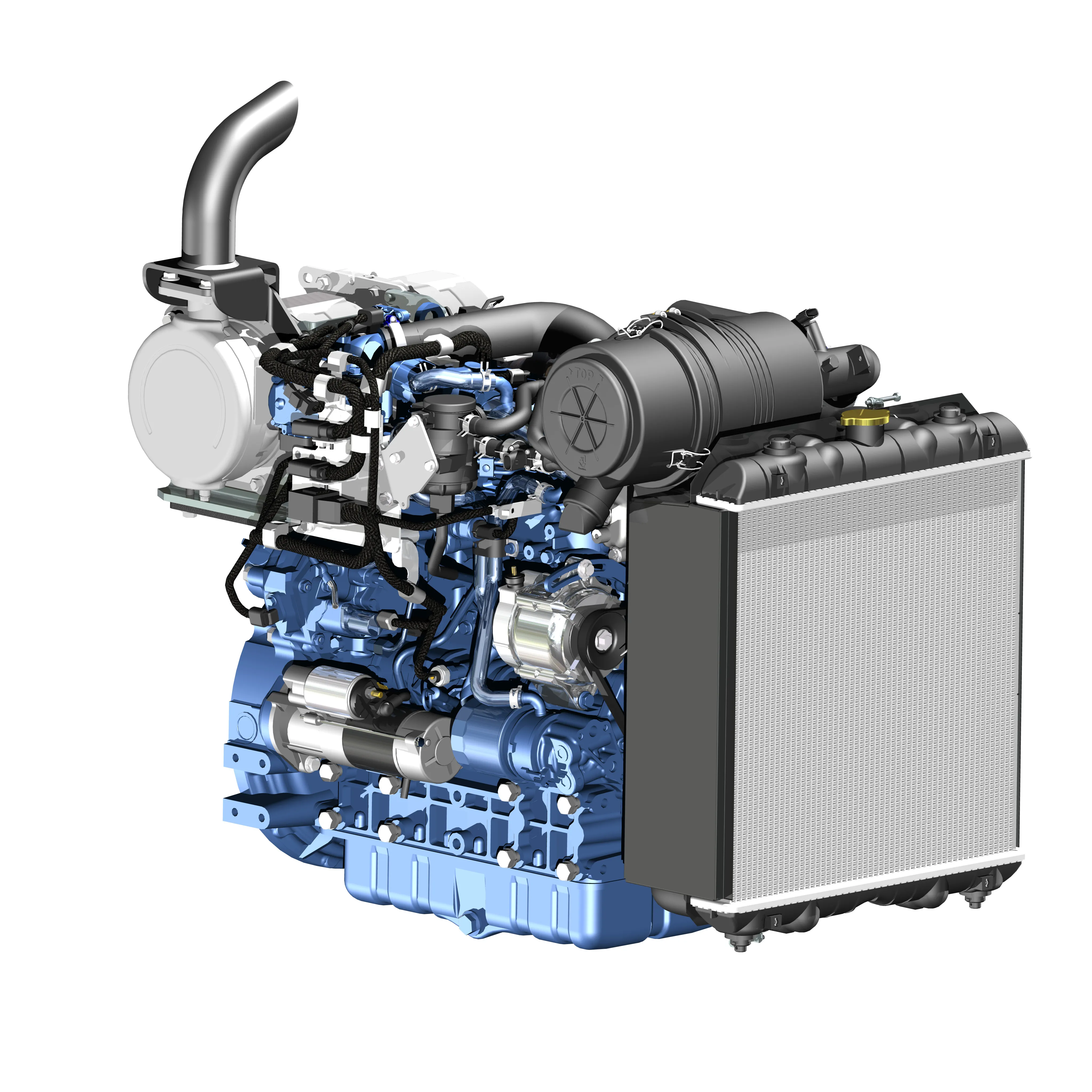

1265 Kubota is offering new diesel power pack options in the power class up to 55kW. These have been designed for customers and to meet current and proposed future regulations. The technology uses common rail technology and state-of-the-art exhaust gas treatment. This will Kubota’s OEM customers have the right engine solution to effectively develop machines that meet emissions targets according to the firm. The new power packs also provide a ready base for when Stage V emissions legislation does comes into effect in 2019. Whilst the final and finer details of Stage V are still being debated in Brussels, the launch of the power packs will ensure that Kubota and its OEMs will be ready, the company claims. The firm says that the new power packs are reliable, durable and compact. In certain configurations, up to 100% power at the side PTO may be possible, a key feature for engines working in confined installations.