In recent years developments in engine technology have played a key role with regard to improved machine performance. Diesel engine makers have had to meet a challenging schedule in terms of delivering new low emission engine technology and meet tough regulatory requirements for the US and Europe. Along with the cleaner emissions have come improved fuel economy and increased power density, allowing customers to meet the power needs of their machines with smaller and more economical engines. At the same time

November 14, 2016

Read time: 4 mins

In recent years developments in engine technology have played a key role with regard to improved machine performance. Diesel engine makers have had to meet a challenging schedule in terms of delivering new low emission engine technology and meet tough regulatory requirements for the US and Europe. Along with the cleaner emissions have come improved fuel economy and increased power density, allowing customers to meet the power needs of their machines with smaller and more economical engines. At the same time, service schedules have been extended in many instances.

However, further gains in machine efficiency are now being delivered from another angle, with diesel electric systems, hybrid drives and new CVT transmissions now available on the market. Prototype construction machines with hybrid drives were first shown over 10 years ago. But2300 Komatsu was the first manufacturer to offer a hybrid excavator on the market, with an electric slew system driven by recirculated electrical power drawn from a capacitor. Other firms followed suit with similar technologies, although 178 Caterpillar opted to break the mold by using a hydraulic accumulator to store and recycle power in its hybrid excavator instead.

Other construction machines now feature hybrid drives as well.233 Hitachi unveiled its Japanese-designed ZW220HYB-5 hybrid wheeled loader in 2015, again featuring electric wheel motor drives and power storage using capacitors. Meanwhile 228 Hamm recently announced a hydraulic hybrid energy system for a compactor; currently undergoing field testing and due for commercial availability in the next few years.

Diesel electric drives have been used in large capacity dump trucks for many years, although the development of more efficient AC drives around 20 years ago brought about a significant gain in performance over earlier generation DC systems. Caterpillar has also introduced a sophisticated diesel electric drive with AC technology for its D7E bulldozer. And257 John Deere has been offering a wheeled loader with a diesel electric drive for some time in the shape of its 644K model, which features switched reluctance type wheel motors.

Manufacturers have also started introducing new continuously variable transmission (CVT) systems that offer higher working efficiency. Caterpillar now offers CVTs as an option on a number of its models. Meanwhile,718 Liebherr recently went one step further with its latest generation of large wheeled loaders. These are equipped with innovative drivetrains that combine Liebherr’s trademark hydrostatic drives with mechanical type CVT transmissions, delivering the best of both systems.

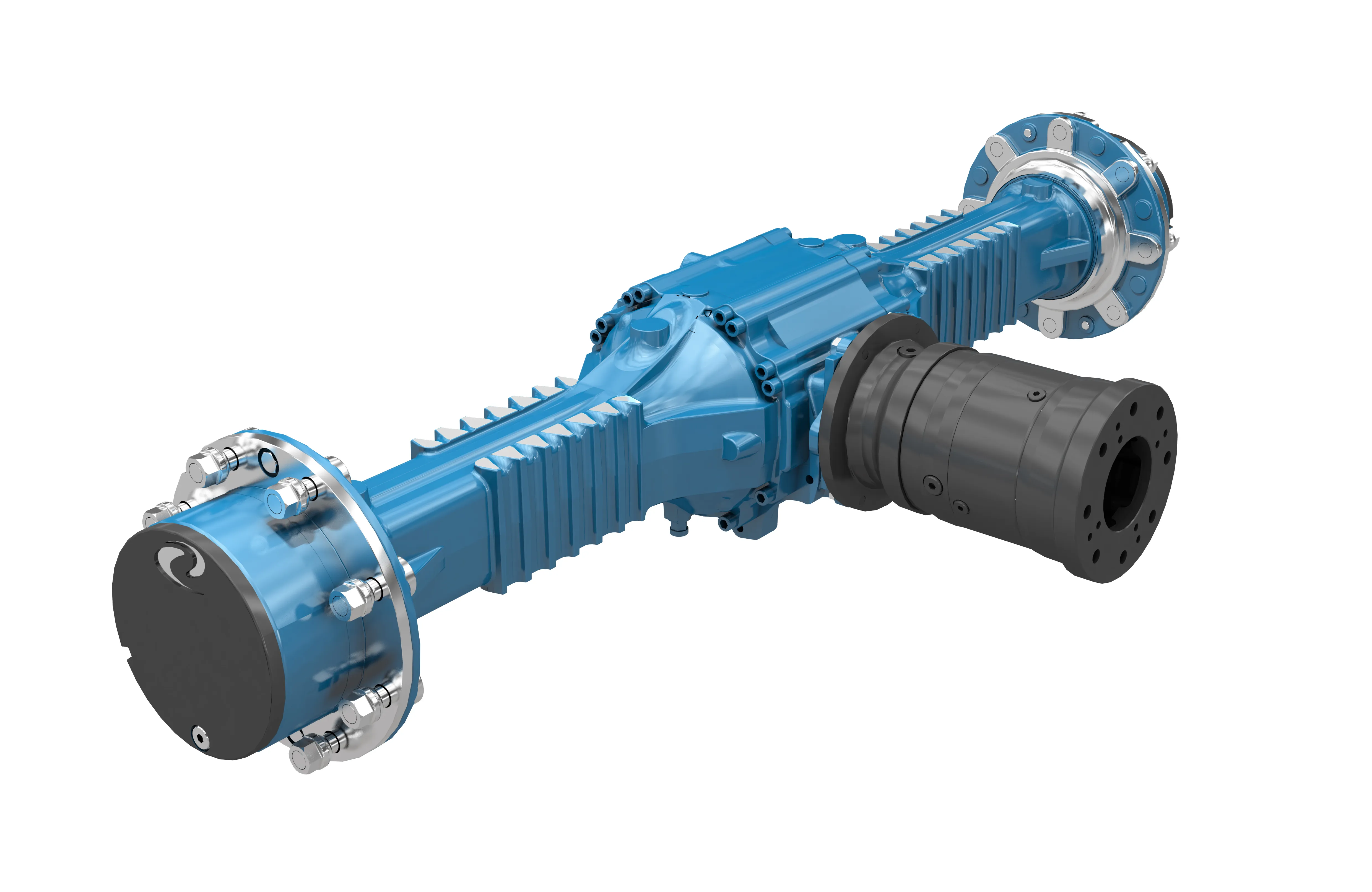

And the driveline advances will continue. Driveline manufacturers such as2304 ZF and 2254 Dana are working on new and more efficient CVT systems. And transmission specialist 7214 Oerlikon Fairfield recently unveiled its innovative electric drive system for off-highway vehicles at an event held in Germany. The system integrates an Oerlikon Fairfield Torque Hub planetary drive with an Interior Permanent Magnet Motor, itself produced by Ashwoods Electrical Motors. This provides a compact drive solution that Oerlikon Fairfield claims is up to 70% smaller and lighter and 20% more efficient than motors used previously in off-highway applications.

According to Oerlikon Fairfield, this new system is also competitively-priced compared with previously available technology. The firm says that the compact design allows the system to provide a steerable four-wheel-drive configuration where earlier generation technologies would have been too bulky.

The unit can deliver 4000Nm of drive torque and 5600Nm of braking torque, while the motor is smaller and lighter than current solutions featuring larger, brushed DC or induction motors coupled to a planetary gearbox. The new package is said to provide a triple planetary ratio in the length of the standard double planetary design.

Meanwhile, combining the two technologies with an integrated electric parking brake has allowed the elimination of duplicated components, saving weight, complexity and space. The Oerlikon Fairfield Torque-Hub planetary drive is already well-proven and is used in a number of off-highway vehicles, with options of single planetary, double planetary, triple planetary and differential planetary gearing configurations. Combining the planetary drive with the new compact motor is making a further step in performance however.

Dynamometer testing of this innovative drive system has been completed and the firms says that field testing is now currently underway. How long it will take before the system is available commercially has yet to be revealed, but it will be of major interest when it come onto the market.

However, further gains in machine efficiency are now being delivered from another angle, with diesel electric systems, hybrid drives and new CVT transmissions now available on the market. Prototype construction machines with hybrid drives were first shown over 10 years ago. But

Other construction machines now feature hybrid drives as well.

Diesel electric drives have been used in large capacity dump trucks for many years, although the development of more efficient AC drives around 20 years ago brought about a significant gain in performance over earlier generation DC systems. Caterpillar has also introduced a sophisticated diesel electric drive with AC technology for its D7E bulldozer. And

Manufacturers have also started introducing new continuously variable transmission (CVT) systems that offer higher working efficiency. Caterpillar now offers CVTs as an option on a number of its models. Meanwhile,

And the driveline advances will continue. Driveline manufacturers such as

According to Oerlikon Fairfield, this new system is also competitively-priced compared with previously available technology. The firm says that the compact design allows the system to provide a steerable four-wheel-drive configuration where earlier generation technologies would have been too bulky.

The unit can deliver 4000Nm of drive torque and 5600Nm of braking torque, while the motor is smaller and lighter than current solutions featuring larger, brushed DC or induction motors coupled to a planetary gearbox. The new package is said to provide a triple planetary ratio in the length of the standard double planetary design.

Meanwhile, combining the two technologies with an integrated electric parking brake has allowed the elimination of duplicated components, saving weight, complexity and space. The Oerlikon Fairfield Torque-Hub planetary drive is already well-proven and is used in a number of off-highway vehicles, with options of single planetary, double planetary, triple planetary and differential planetary gearing configurations. Combining the planetary drive with the new compact motor is making a further step in performance however.

Dynamometer testing of this innovative drive system has been completed and the firms says that field testing is now currently underway. How long it will take before the system is available commercially has yet to be revealed, but it will be of major interest when it come onto the market.