This is a long and large project, the biggest national new district in China, according to Gansu Road & Bridge Maintenance Corp. However, the development of the district, the fifth in China, is essential to the country’s future. It provides an important connection between the Silk Road Economic Belt and the Eurasian continental bridge. The Silk Road Economic Belt is one component of the larger Belt and Road Initiative, an enormous nationwide infrastructure development project.

The Ammann ABA 320 UniBatch Asphalt-Mixing Plant will produce asphalt for all elements of the district’s infrastructure. The plant will operate almost continuously over the next decade to supply asphalt.

The project will deliver a modern, small-scale city on the Silk Road and provide a key industrial base for the country. The Lanzhou area is mostly undeveloped and the few asphalt plants there or nearby are low-cost, domestic alternatives that offer limited technology and production.

Gansu Road & Bridge opted for the Ammann plant in part due to its extremely low emissions. The Chinese government has dictated that emissions be minimised and other sustainable efforts taken – including covering the entire plant to lessen dust and reduce sound.

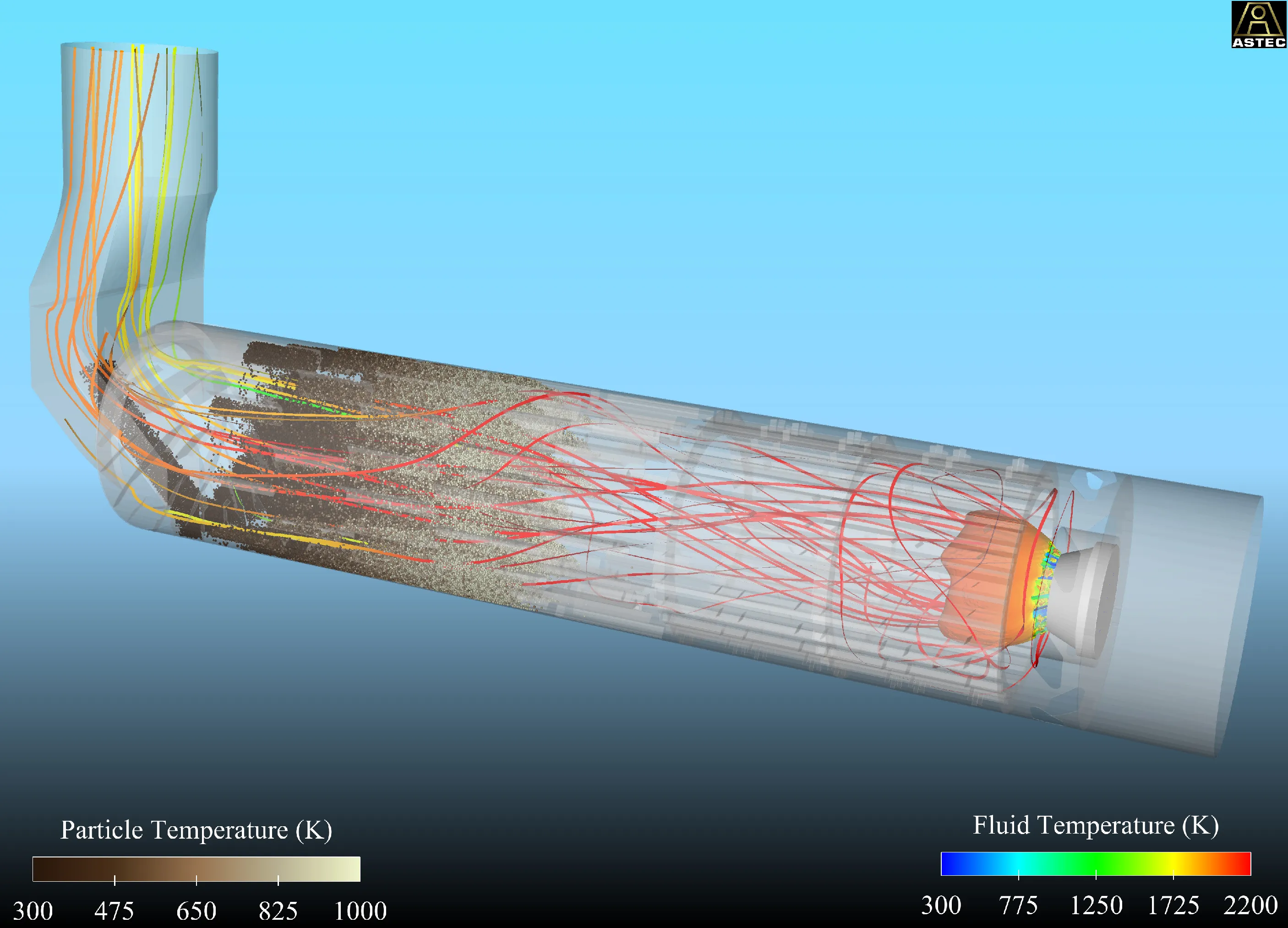

ABA UniBatch plants utilise an efficient drying and heating process that conserves energy and ultimately reduces costs. The burner control regulates the drying process to ensure reduced fuel consumption and low emissions.