A new range of equipment from SHANBAO has helped to increase limestone production to meet Henan Province's aggregates demand. SHANBAO has supplied a full range of equipment to two companies in a growth region of China.The Chinese-based manufacturer of stationary crushing and screening equipment supplied the equipment to Yongsheng Aggregates and Yongye Trading. The crushing, screening and feeding equipment is being used to process limestone that supplies 10% of the aggregate requirements in the Henan region'

May 8, 2012

Read time: 3 mins

A new range of equipment from SHANBAO has helped to increase limestone production to meet Henan Province's aggregates demand

The Chinese-based manufacturer of stationary crushing and screening equipment supplied the equipment to Yongsheng Aggregates and Yongye Trading.

The crushing, screening and feeding equipment is being used to process limestone that supplies 10% of the aggregate requirements in the Henan region's capital, Zhengzhou city.

Yongsheng Aggregates and the Yongye Trading are both located in Jianyu town, Yingyang district in Henan Province, central China.

Henan Province has traditionally been seen as an economic backwater, but recent developments have seen promising growth throughout the region. One of the foundations of this growth has been the mineral wealth in the area, which is of particular relevance to both companies as the locality surrounding Jianyu is the main aggregates production base for development projects within Henan region's capital Zhengzhou city.

Both companies possess bases of operation within Jianyu, which supplies 80% of aggregate requirements for various construction projects within Zhenhzhou, with the two companies supplying 10% of the aggregates requirements themselves.

Due to the proximity of Jianyu to Zhengzhou city, some 32km away, the supply of aggregates is easily accomplished, with the greater challenge being to match supply to demand.

Following on from the reform of Chinese Aggregates Policy in 2010 it was decided to increase production capacity by adding two new production lines in 2011. But in order to satisfy the increasing demand each of the lines would be required to possess a capacity of 10,000tonnes/day.The company turned to in order to supply equipment capable of achieving such high rates of production was Shanghai Jianshe Luqiao Machinery, which trades under the SHANBAO name.

The relationship between the three companies dates back to 2003 when a primary crushing line was established, based around the SHANBAO PE 750x1060 jaw crusher.

Based on what proved to be a positive experience of SHANBAO equipment, when the time came to increase production capacity it was decided to stick with this proven supplier.

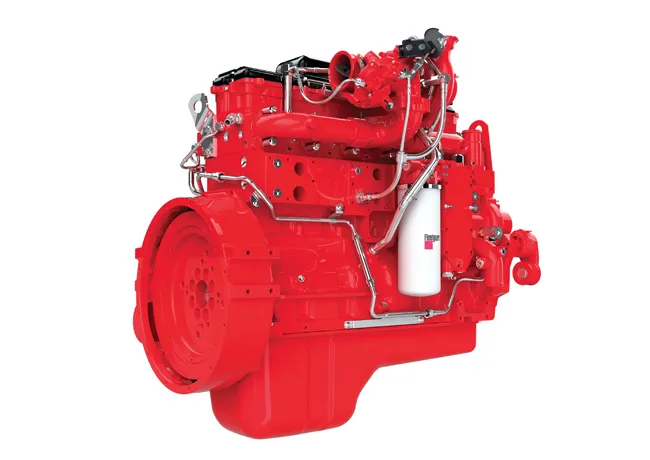

After consultations with the SHANBAO planning team it was decided that the 10,000tonnes/day target for each production line could be achieved using two feeders (ZSW600X180); two jaw crushers (PE 1200X1500); 12 impact crushers (PF1315); ten vibrating screens (2YK 3072); two vibrating screens (YK1545), and 12 small feeders (GZG1003).

This array of products was installed by SHANBAO personnel, who also provide invaluable aftermarket care and support, an area where SHANBAO has developed a reputation, "second to none" in China. The professional support provided covers basic preparation work, equipment installation and testing, production testing, as well as ensuring the machinery is properly maintained and serviced in a pro-active manner.

Aggregate production lines such as those installed in Jianyu have enabled impressive production figures to be achieved, while producing consistent product shapes.

From SHANBAO's modern manufacturing facilities in Shanghai customers are provided with a full range of products, and the company is aiming to improve its global capabilities in order to enhance its product and service portfolio to both domestic and international customers.

It is envisaged that this will allow SHANBAO to expand and further develop its business into new markets.