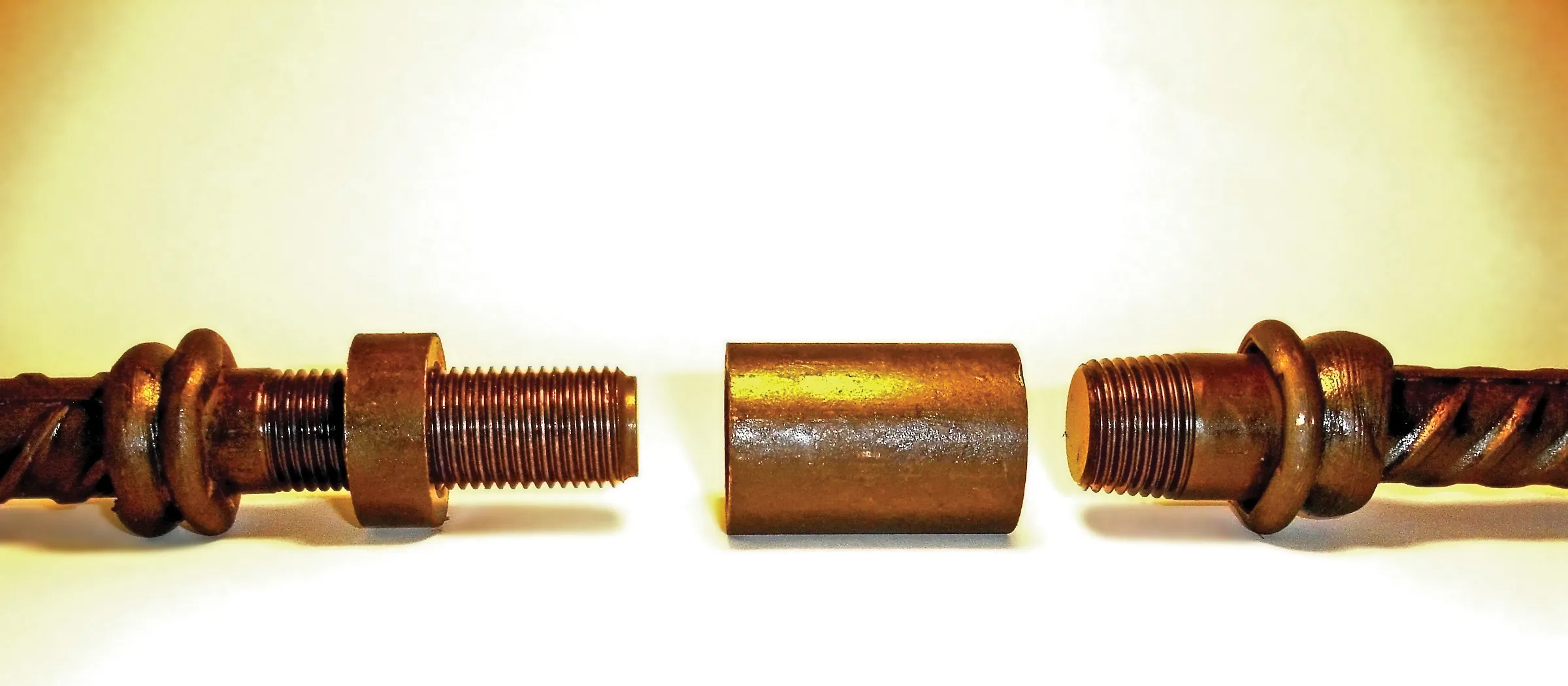

Hy-Ten's new positional couplers are said to speed up site construction times by using reverse cut threads to link together both reinforcement bars by turning the sleeve in one direction. Richard Webster, director at Hy-Ten, said: "We launched our standard range of friction welded couplers just 12 months ago and the concept has been enthusiastically accepted by both engineers and contractors. The new positional couplers extend the application of this concept into areas where reinforcement bars are immovabl

April 16, 2012

Read time: 2 mins

Hy-Ten's new positional couplers are said to speed up site construction times by using reverse cut threads to link together both reinforcement bars by turning the sleeve in one direction

Richard Webster, director atFriction welding is said by Hy-Ten to be a new concept in construction, but the technology has been used in aerospace and automotive applications, where joints formed by this method are subject to extreme stress and high workload.

Hy-Ten said its machines securely hold the bar while rotating the coupler at high speed so that the mating surfaces plasticise and achieve a low fusing temperature, creating a joint that is far stronger than those derived from conventional welding.

The new HT (P) and HT (EP) couplers in the 16mm and 40mm diameter range have been fully tested and certi ed by CARES, the certi cation authority for reinforcement steel.