This is one of the industry’s first public tests of a fully autonomous compactor on a live construction site, rather than under test at specially prepared areas.

The job is for the construction of an earth covered dam and the Dynapac compactor was used alongside conventional machines guided by operators to carry out the work. Trimble technology used in all of the soil compactors ensuring they worked as a team, covering the entire area efficiently.

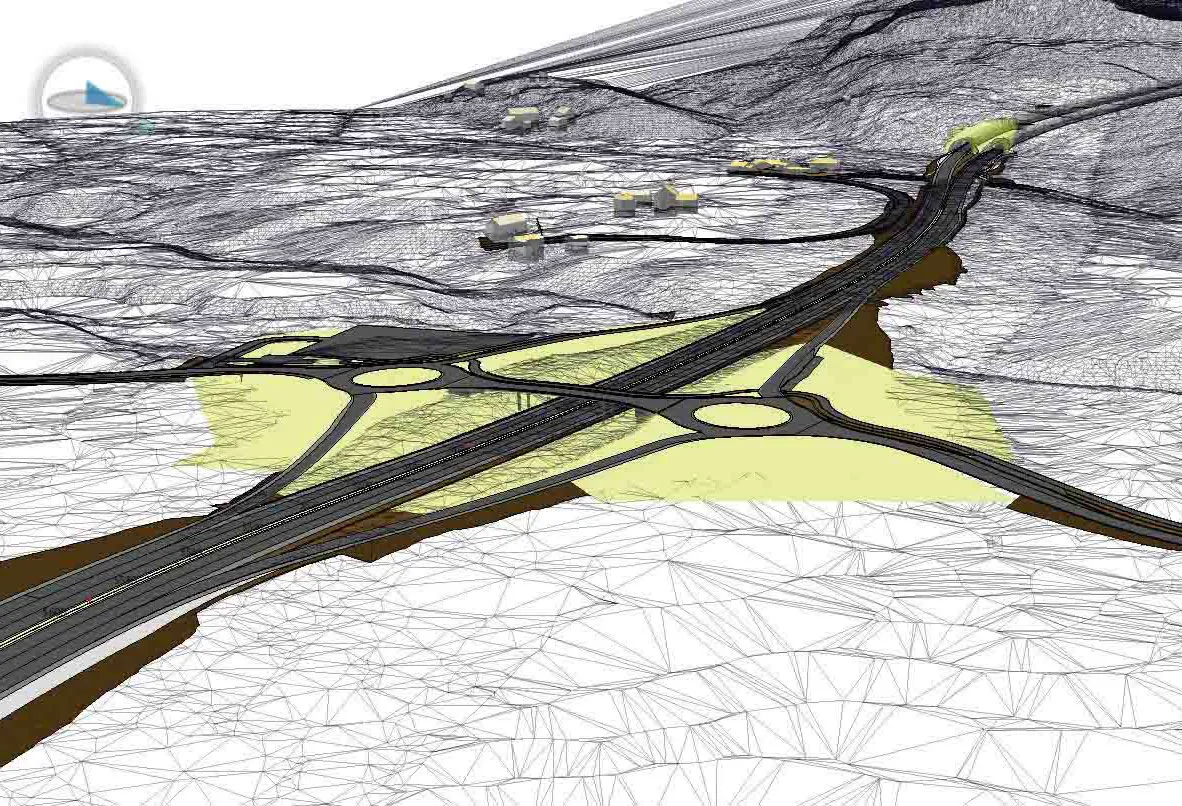

The Trimble Earthworks Grade Control Platform for Autonomous Compactors was used to guide the Dynapac CA 5000 soil compactor. The project is for the Site C Clean Energy Project on the Peace River in northeast British Columbia.

For some of the time, an operator did sit in the machine to oversee its working while the compactor was under autonomous control.

At other times the machine was used without a person in the cab when handling work close to an edge that would have posed risks for an operator. To optimise safety, the machine operated in geofenced areas on the site and was also fitted with safety systems to detect the presence of personnel.

According to Trimble the fully autonomous machine completed 37 hours of real compaction work, operating alongside a mixed fleet of compactors, the rest of which were running the Trimble CCS900 Compaction Control System. Data from all machines – both with and without an operator – was delivered using Trimble WorksOS Software, which is being used as the system of record for all compaction data on the jobsite.

“The Site C project was the perfect place to begin live testing of the fully autonomous soil compactor because of the cost and safety benefits autonomy will bring to large infrastructure projects like this in the future, and because of the willingness of the project owner and contractor to use new technology on their jobsite,” said Cameron Clark, earthmoving industry director for Trimble’s civil infrastructure solutions. “We are pleased that this initial testing reinforces our philosophy that autonomous technology will play an important role in delivering a cheaper, faster, safer and greener future for the construction industry.”

Clark said that operating data from the machines has also been used in the model of record for the project.

The Site C Clean Energy Project is a BC Hydro hydroelectric dam being built in northeastern BC. When complete, it will provide 1,100MW of electricity each year, enough to power 450,000 homes or 1.7 million electric vehicles. Prime contractors include ACCIONA Infrastructure Canada Inc. and Samsung C&T Canada, among others. The role of ACCIONA and Samsung includes construction of an earthfill dam, two diversion tunnels and a roller-compacted concrete foundation for the generating station and spillways.

While the mining sector has been running autonomous haul trucks on sites for over 20 years, these have been in controlled working areas and on large machines. Using autonomous machines in construction operations poses more challenges as the sites are more dynamic. This new development is a significant step for the construction sector and will be followed by other applications of autonomous machine technology.

According to Clark, the highly repetitive soil compactor working cycle is particularly well suited to the use of autonomous machines, although the firm is developing autonomy solutions for other types of machines that could be used in certain duties. The firm has previously demonstrated an excavator working autonomously for trenching work. But Clark explained that excavators are so versatile that only certain repetitive tasks, such as trenching, suit autonomous operation.