The problem posed by silica dust is a major topic for discussion throughout the US construction industry at present. Enforcement of the Occupational Safety and Health Administration (OSHA) final respirable crystalline silica standard began on September 23rd, 2017, bringing the topic into the mainstream. Although it was developed to protect the health of American workers, the new rule has a much wider significance and throws the spotlight onto the importance of dust control on highway and airport runway construction projects around the world.

The dangers posed by silica dust have been known for some time but only now are regulations becoming much tougher. According to OSHA, in the US alone around 2 million construction workers are exposed to respirable crystalline silica when they drill, cut, crush or grind silica-containing materials such as concrete and stone. This problem is not one to be considered lightly either. Exposure to silica dust can cause silicosis, lung cancer, other respiratory diseases, and kidney disease.

In an effort to address these health problems, the final silica rule requires US construction employers to limit worker exposure to respirable crystalline silica in a range of construction activities including dowel pin drilling and concrete sawing, both of which play vital roles in highway, road and runway projects. With concrete paving a well-proven method of road and airport runway construction, maximising safety for worksite personnel can be crucial and the new US requirements are equally of note for other territories.

The silica rule means that construction employers covered by the new OSHA standard have two alternatives to satisfy the requirements. Firstly, employers have to measure their workers’ exposure to silica and independently determine which dust controls work best to reduce exposure to the new permissible exposure limit (PEL). However, these exposure measurements can be expensive and time-consuming to perform. In addition, employers have to use a dust control approach outlined in “Table 1: Specified Exposure Control Methods When Working with Materials Containing Crystalline Silica.” The Table 1 lists effective dust control methods and work practices that can be used to achieve the requirements of the new rule.

According to the Table 1 section on dowel pin drilling, for tasks performed outdoors only, operators can comply by using a shroud around the drill bit with a dust collection system. The dust collector must have a filter with 99% or greater efficiency, as well as a filter-cleaning mechanism.

The Table 1 section on dowel pin drilling also states that workers must use a respirator with an assigned protection factor (APF) of at least 10. A HEPA-filtered vacuum must be used when cleaning holes.

Dust collection offers a safety solution for site personnel that can meet worldwide requirements. Those international employers not subject to the OSHA rules in the US can also help to boost the safety of site personnel on highway, road and runway construction projects by obtaining a dowel pin drill dust collection system that meets the stringent Table 1 requirements.

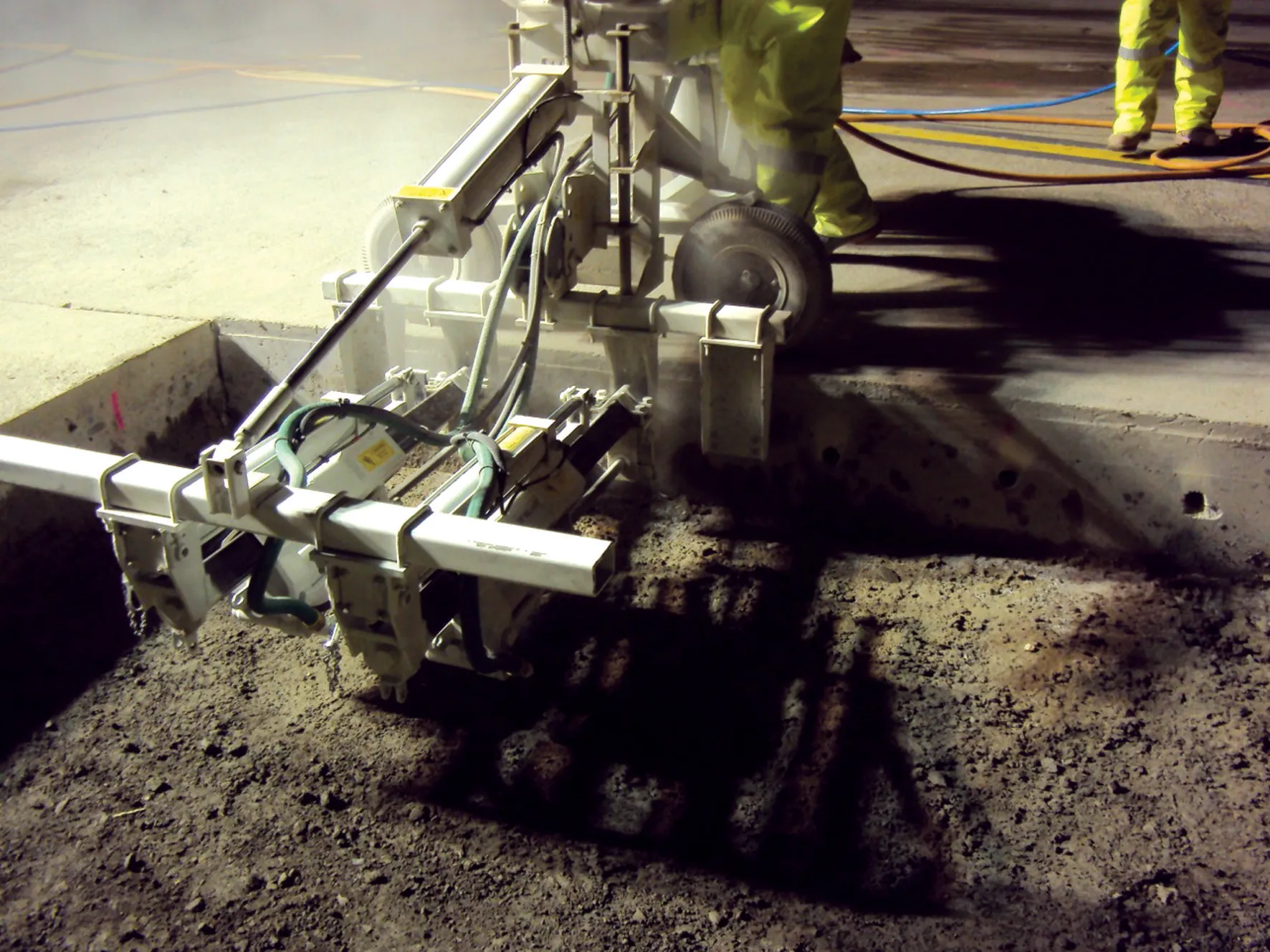

As an example, the

The compact, canister-style unit can be retrofitted to any Minnich drill or adapted to fit other drill makes and models. The system runs off the same air compressor used for drilling, eliminating the need for an additional power source.

While international companies may not need to comply with requirements of the OSHA silica rule, they can better protect workers from potentially harmful silica dust exposure with readily available technologies. And with the risk of silica dust now recognised in the US, employers in other territories not currently subject to those rules could protect themselves against future claims by investing in proven technology now.