Naue Geosynthetics says its Secugrid offers a solution for a host of ground preparation problems, and for use in reinforced retaining walls.

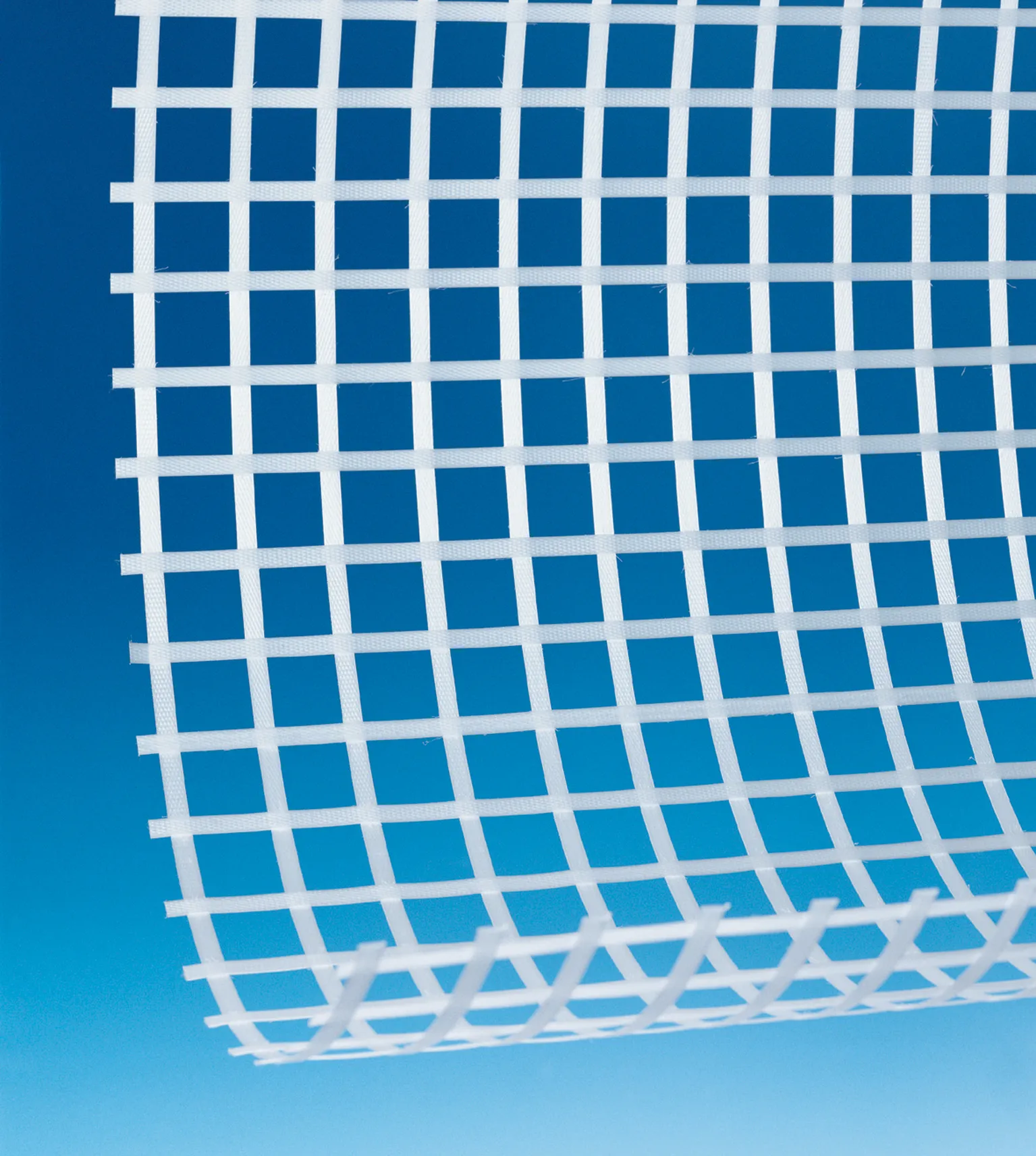

Secugrid is a geogrid made from extruded monolithic flat bars with welded junctions, for soil reinforcement in earth, landfill and road construction as well as in hydraulic engineering applications.

Among its benefits are said to be its high strength and low elongation thanks to the extruded elements.

"The monolithic flat bars give it a robust construction, an

April 16, 2012

Read time: 3 mins

Naue Geosynthetics says its Secugrid offers a solution for a host of ground preparation problems, and for use in reinforced retaining walls.

Secugrid is a geogrid made from extruded monolithic flat bars with welded junctions, for soil reinforcement in earth, landfill and road construction as well as in hydraulic engineering applications.Among its benefits are said to be its high strength and low elongation thanks to the extruded elements.

"The monolithic flat bars give it a robust construction, and the welded junctions ensure that the grid has an inherent stiffness which is maintained throughout the application," says

Formulated from polyethylene or polypropylene resins, the grid offers tensile strengths ranging from 20kN/m to 400kN/m, making it suitable for demanding projects.

It resists surface tensile force loading with very low elongation, resulting in an immediate force connection and interlocking with the fill soil.

Those specifying Secugrid are also offered environmental and cost benefits. These geogrids can save natural mineral resources by reducing base course thickness for pavements, and steep slope construction, reducing the need for large volumes of stabilising soil fill.

Secugrid is available in a wide range of options to suit varying ground conditions and applications. These applications include base courses in conventional road engineering, park, industrial and storage areas, steep earth slopes and retaining structures, and areas prone to subsidence.

The company also offers a software package aimed at engineers involved in the design of ground reinforcement.

SecuSlope is a Windows-based interactive, design-oriented program specifically written for Secugrid geogrid-reinforced slopes, walls and abutments.

Engineers can use the software to calculate the optimal layout (length and spacing) of the Secugrid reinforcement layers for a selected design.

The program takes into account strength, reduction factors and design safety factors.

It also considers pore water pressures and seismicity, and designs according to US Federal Highways Authority (limit equilibrium) or BS8006 (ultimate limit state).

While the program is fully operational in English, it has a built-in report which can be printed in several languages.

The software package is available free of charge to all engineers involved in the design of ground reinforcement for areas such as embankments, load transfer of overlying soil masses, spanning voids and sink holes, and trench covers and beds.