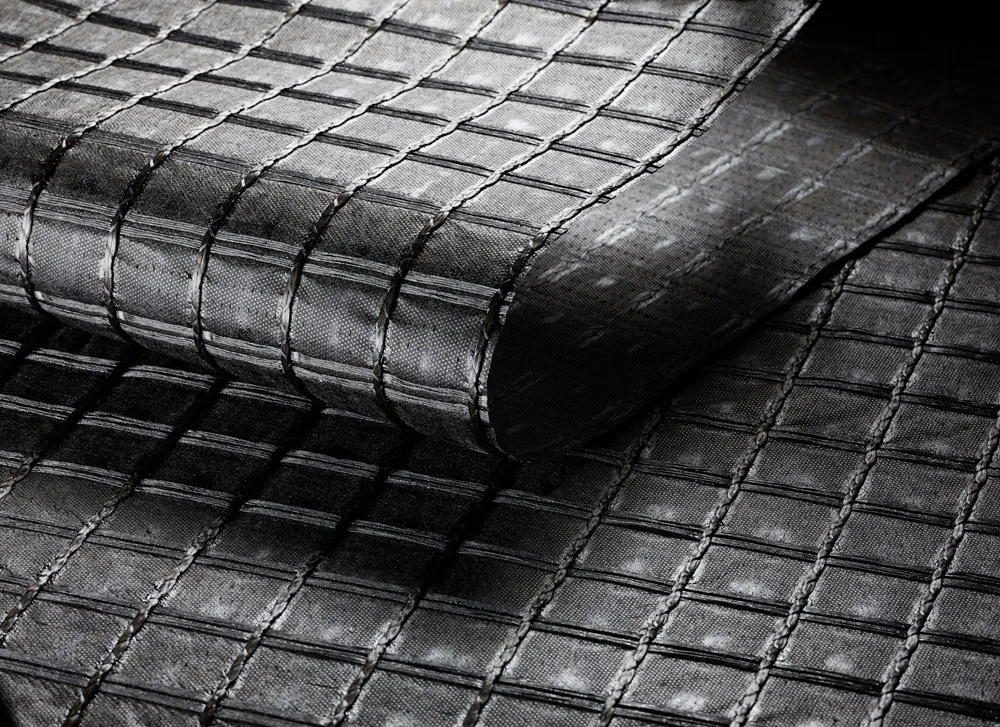

The firm’s HaTelit product can extend the service life of asphalt pavements, reducing the time it takes for reflective cracking to become a problem by a factor of four. Other benefits include shorter construction times and lower CO2 emissions from congestion around construction sites as a result.

The HaTelit asphalt interlayer product has been optimised since it was first introduced. It can lengthen maintenance intervals, reduce maintenance effort and cost, and cause less disruption.

Reflective cracking is one of the most common types of failure in asphalt road construction. Exposure to traffic loads, daily freeze-thaw cycles and seasonal temperature variations encourage the upward propagation of cracks in the base to the pavement surface. The infiltration of water and oxygen into the asphalt hastens the deterioration of the road condition. Standard rehabilitation methods for cracking in roads often involve renewal of the binder and surface courses. However, HaTelit simplifies the repair procedure: instead of milling off and replacing the binder course, a user can install the asphalt reinforcement directly on top of it. By taking up the tensile stresses and preventing overloading of the asphalt, the reinforcement grid delays existing cracks from propagating into the surface course.

Depending on the type and nature of the pavement to be repaired and the planned rehabilitation solution, the HUESKER Group recommends geosynthetic reinforcement products made from polyester (PET) or polyvinyl alcohol (PVA).