The Greppoli Tunnel is located between Grosseto and Siena in the section of road near Civitella Paganico on the SGC E 78. The route connects the Tyrrhenia coast with the Adriatic and is a major highway, connecting Grosseto to Fano. The 100m-long Greppoli Tunnel was one of the many works carried out for the project.

Due to the geology, the short length of the tunnel and the close proximity of an existing tunnel carrying live traffic, it was decided to use the breakers instead of risking drilling and blasting. The breakers were used by contractor Strabag, one of the team of firms comprising the Nuova FARMA Scarl Consortium carrying out the work on the route. A similar method is also being used for the larger Casal di Pari tunnel, which also lies along the route.

Data obtained from geological surveys indicated that the rock conditions featured cavernous limestone with medium-poor mechanical characteristics. However, during excavation it was realised that some of the rock was of a poorer quality so the engineering team opted to use short-term face reinforcement with injected fibreglass tubes and reinforcement elements. The works extended the project completion time, but were in order to guarantee medium-term stability.

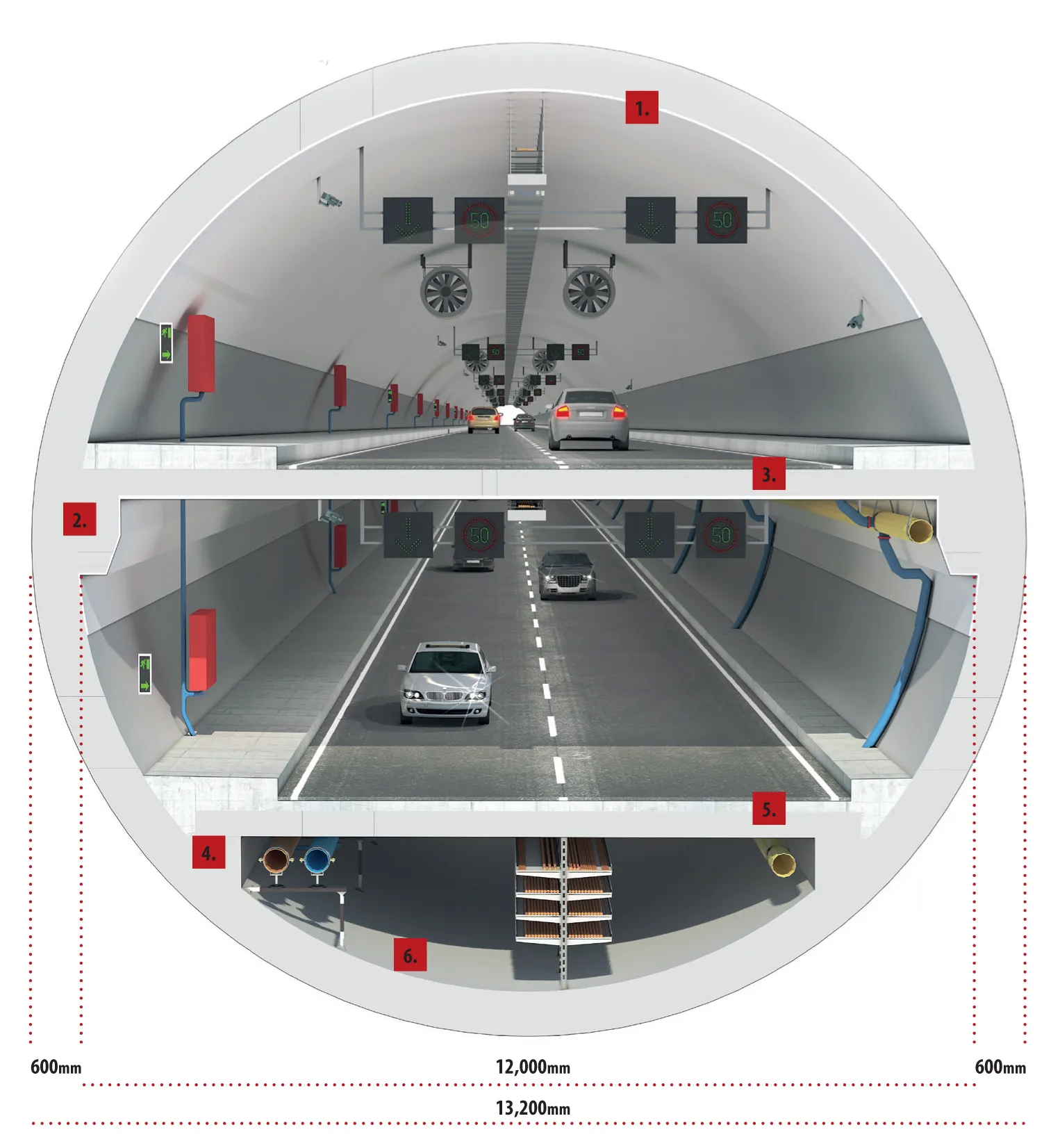

The tunnel measured 100m long, with face areas of 136-143m2, allowing two carriageways as well as an emergency lane. Initially, due to the hardness and compactness of the rock, excavation output was low and chisel wear was higher than average. However, by switching to the Cobra tools, productivity was increased. This continued once the fractured material was reached, with excavation stabilising at an average 14m3/per hour. This allowed an average advance rate of 2m/day, including the time required for shotcreting, rib assembly and installation.