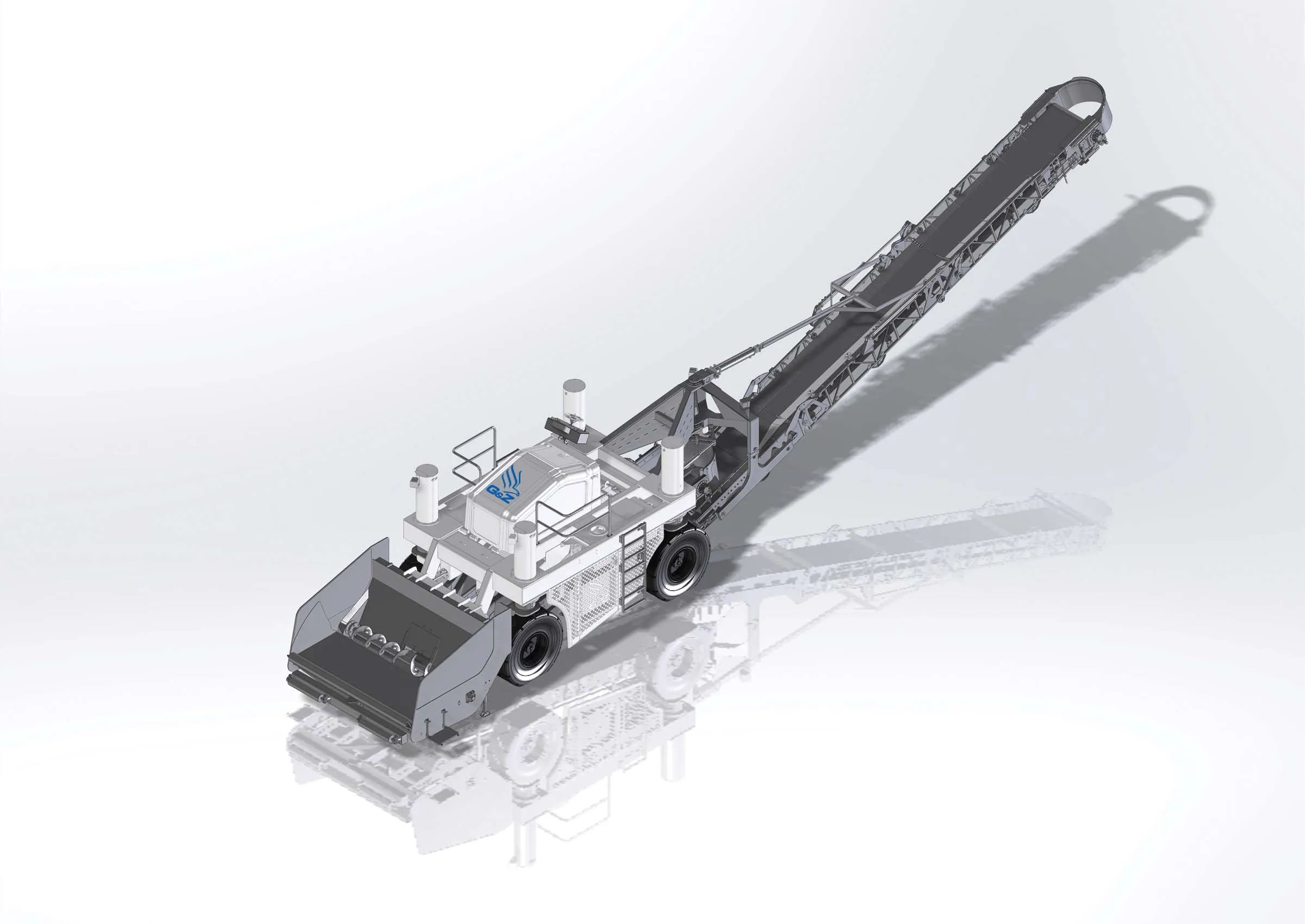

According to Atlas Copco Dynapac, its new CT3000 tamping compactor offers rapid and efficient operation. The machine has been designed to efficiently achieve specified densities on cohesive and semi-cohesive soils.

With an operating weight of 22.5tonnes and an average production capacity of 820.7m3/h, the Dynapac CT3000 is ideal on projects such as highways and airport runways, where large-volume earthmoving is required.

Power comes from a 194kW Cummins turbo-diesel engine, which drives through an au

August 17, 2015

Read time: 2 mins

According to 161 Atlas Copco Dynapac, its new CT3000 tamping compactor offers rapid and efficient operation. The machine has been designed to efficiently achieve specified densities on cohesive and semi-cohesive soils.

With an operating weight of 22.5tonnes and an average production capacity of 820.7m3/h, the Dynapac CT3000 is ideal on projects such as highways and airport runways, where large-volume earthmoving is required.

Power comes from a 194kW196 Cummins turbo-diesel engine, which drives through an automatic four-speed transmission. This system is said to deliver optimum all-wheel traction for high productivity, with an efficient power transfer to the final drive.

The front oscillating axle works independently of the optional strike-off blade and the rigid rear axle. This enables the blade to work in a permanently level position. The square pads of the compacting drums are optimised for energy transmission to the soil, allowing the unit to deliver uniform compaction density with minimum scarification.

The drums are offset by the width of a pad so that the rear drum compacts areas that have not been compacted by the front drum. A double pass of the machine delivers a compaction width of 4.42m.

The novel design has the drum mounted on air-filled rubber tyres, reducing vibration for the operator. The pad drums can easily be removed for ease of transportation.

Meanwhile, the operator station has a swivelling seat, good all-round visibility and ergonomic controls with an LED panel displaying key machine information.

The hydrostatic steering allows a steering angle of 40° to either side and a turning radius of less than 6.4m.

With an operating weight of 22.5tonnes and an average production capacity of 820.7m3/h, the Dynapac CT3000 is ideal on projects such as highways and airport runways, where large-volume earthmoving is required.

Power comes from a 194kW

The front oscillating axle works independently of the optional strike-off blade and the rigid rear axle. This enables the blade to work in a permanently level position. The square pads of the compacting drums are optimised for energy transmission to the soil, allowing the unit to deliver uniform compaction density with minimum scarification.

The drums are offset by the width of a pad so that the rear drum compacts areas that have not been compacted by the front drum. A double pass of the machine delivers a compaction width of 4.42m.

The novel design has the drum mounted on air-filled rubber tyres, reducing vibration for the operator. The pad drums can easily be removed for ease of transportation.

Meanwhile, the operator station has a swivelling seat, good all-round visibility and ergonomic controls with an LED panel displaying key machine information.

The hydrostatic steering allows a steering angle of 40° to either side and a turning radius of less than 6.4m.