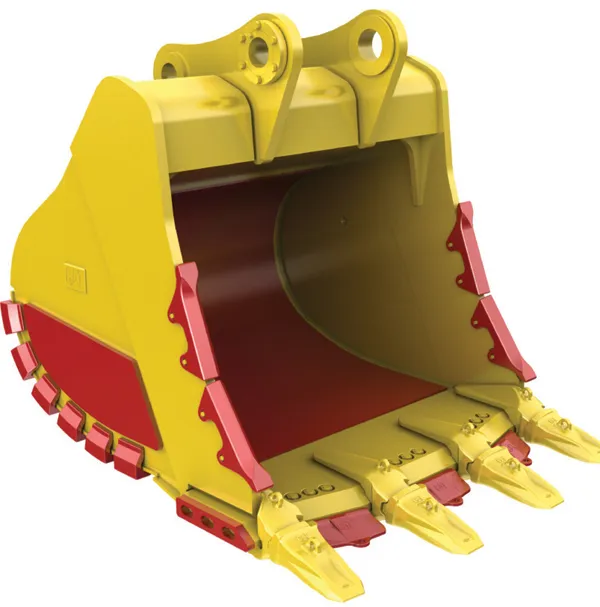

Caterpillar Work Tools is introducing a new line of pin-on and coupler buckets for its 374D and 390D hydraulic excavators, featuring improved designs to take advantage of increased machine performance.

April 5, 2012

Read time: 2 mins

In the near future, the new bucket line will also become available for the E-series excavators.

"Caterpillar has a 35-year legacy designing and manufacturing excavator buckets worldwide. Our engineers have listened to customers operating in various applications around the world and integrated their input into the buckets," said David Becktel, commercial manager Caterpillar Work Tools.

Caterpillar says that with the introduction of the 374D and 390D comes a whole new bucket line with a naming convention that differs from today.

Current excavator buckets in EAME (Europe, Africa, Middle East) are based on four main categories: Excavation (X), Extreme Excavation (EX), Rock (R),

and Heavy Duty Rock (HDR) buckets. The new nomenclature replaces these categories with General Duty (GD), Heavy Duty (HD), Severe Duty (SD), and Extreme Duty (XD).

Caterpillar says the new category names will be used globally and will make bucket identification easier for customers operating across regions.

The D-Series replaces the C-Series in the Caterpillar large HEX line-up, but Caterpillar says this is not a simple machine upgrade.

"As the nomenclature suggests, this is a whole new class of machine. With digging forces increasing significantly, the machines have better potential for productivity than their predecessors. Buckets for the

D-Series are as robust as the machines and are intended to take full advantage of the increased digging performance. All types have been upgraded: from General Purpose through to Extreme Duty. Changes include reinforced top box design, upsized GET and increased capacities.

"The D-Series excavators are robust, powerful machines. Performance increases over the C-Series bring the machines up a size class. Digging forces are increased due to larger bucket and stick cylinder diameters and a longer idler link. The total of these changes equals significant increases of the bucket forces over the earlier models." The General Duty (GD) buckets are for digging in low impact, lower abrasion materials such as dirt, loam, and mixed compositions of dirt and fine gravel, while the Heavy Duty (HD) is for a wide range of impact and abrasion conditions including mixed dirt, clay and sand and gravel.

Severe Duty (SD) is used in higher abrasion conditions such as shot rock and sandstone, and Extreme Duty (XD) is for very high abrasion conditions including high quartzite granite.