National Highways says it has been using Spot, a “robotic dog”, for surveying the agency’s land adjacent to motorways in southwest England.

Spot, a 25kg creation from Boston Dynamics, is being trialled by National Highways, BAM Ritchies - the ground engineering division of BAM Nuttall - and AECOM to inform forthcoming operational work. The robotic dog’s eye view is being employed to capture data remotely in difficult-to-reach locations and across various terrains alongside the motorway and major A roads, according to national Highways.

These access-constrained sites include steep-sided embankments and natural slopes, slopes beneath tree canopies or otherwise obscured by vegetation, culverts and under bridges and other structures. These are areas where it is difficult and sometimes unsafe for geotechnical inspectors to reach.

Spot is to help meet the standards set out in the UK’s Design Manual for Roads and Bridges and reduce the frequency of physical walkover surveys by inspectors and the need for costly and disruptive traffic management.

Boston Dynamics is an American engineering and robotics design company founded in 1992 as a spin-off from the Massachusetts Institute of Technology and whose parent company is now Hyundai Motor Company. The company creates advanced robots that mimic human and animal movements. Boston Dynamics’ other robots include BigDog, Atlas and Handle. Since 2019, Spot has been commercially available, making it the first commercially available robot from Boston Dynamics.

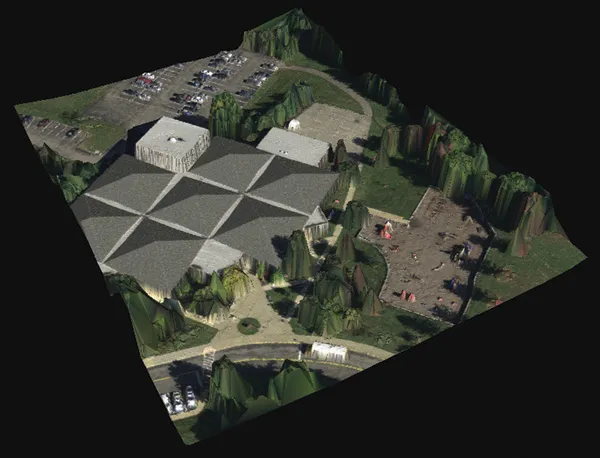

National Highways, a wholly government-owned company, said that Spot has been put through its paces by the AECOM and BAM teams at its Development Centre at Moreton-in-Marsh last summer. The robotic dog’s capabilities were tested over a number of highways settings, across differing ground conditions and on earthworks of various gradients, heights and materials.

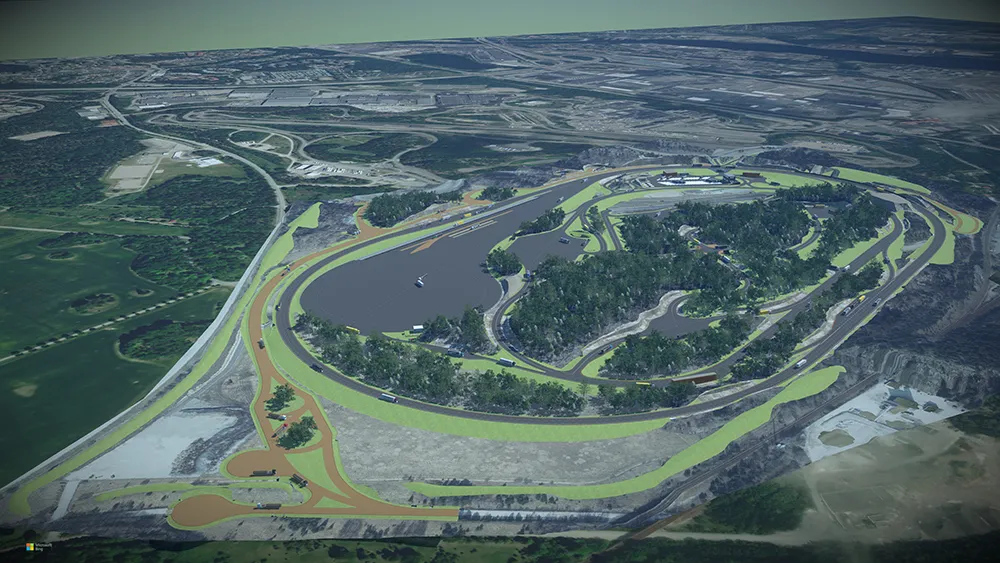

The four-legged robot’s first ‘live trial’ was alongside the M5 in Somerset county, using cameras and a Leica BLK ARC lidar scanner. National Highways said it is keen to explore and test the technology further throughout the year.

“The initial proof-of-concept testing has been encouraging and we’re now live-trialling the robotic tool with a view to using it with our contractors in future survey work,” said Guy Swains, engineering manager with National Highways’ South West Geotechnical team.

“It’s about finding the right applications and the team is focused on realising Spot’s potential,” said Matt Ewing, business development manager with BAM Ritchies.

The trials follow several National Highways research and development projects led by the ARUP/AECOM consortium, to better integrate remote survey techniques into geotechnical asset management practice.

The initiative comes within months of National Highways, the University of Cambridge and supply chain companies launching the Roads Research Alliance to shape the development of innovation within the highways industry over the next five years.