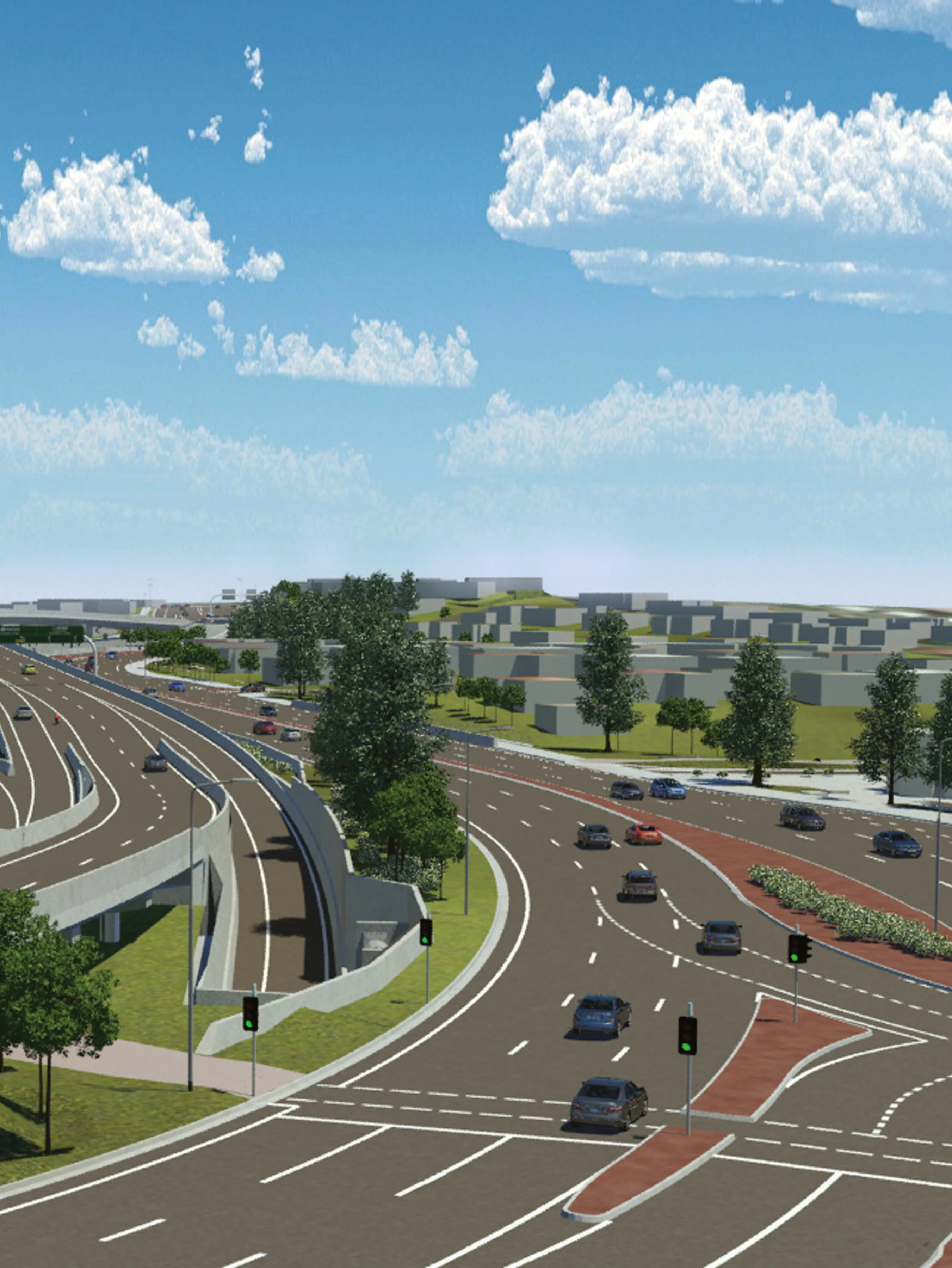

Balfour Beatty and Skanska will carry out a major motorway junction upgrade project worth €69.7 million (£55 million) in the UK. The two companies will operate on the project in a 50:50 joint venture to upgrade junction 30 of the M25 gyratory motorway around capital London. The deal was awarded by the UK’s Highways Agency. This joint venture, Balfour Beatty Skanska, is a construction partner to Connect Plus, the company responsible for managing and upgrading the M25 network. Balfour Beatty Skanska has alrea

December 18, 2014

Read time: 2 mins