Soilmec has launched its new Blue Tech Plus line of pilers with the aim of strengthening and implementing its main objectives: greater efficiency and lower emissions.

The Italy-based manufacturer says the Blue Tech Plus line represents a significant step forward in drilling technology, offering enhanced efficiency and reduced emissions.

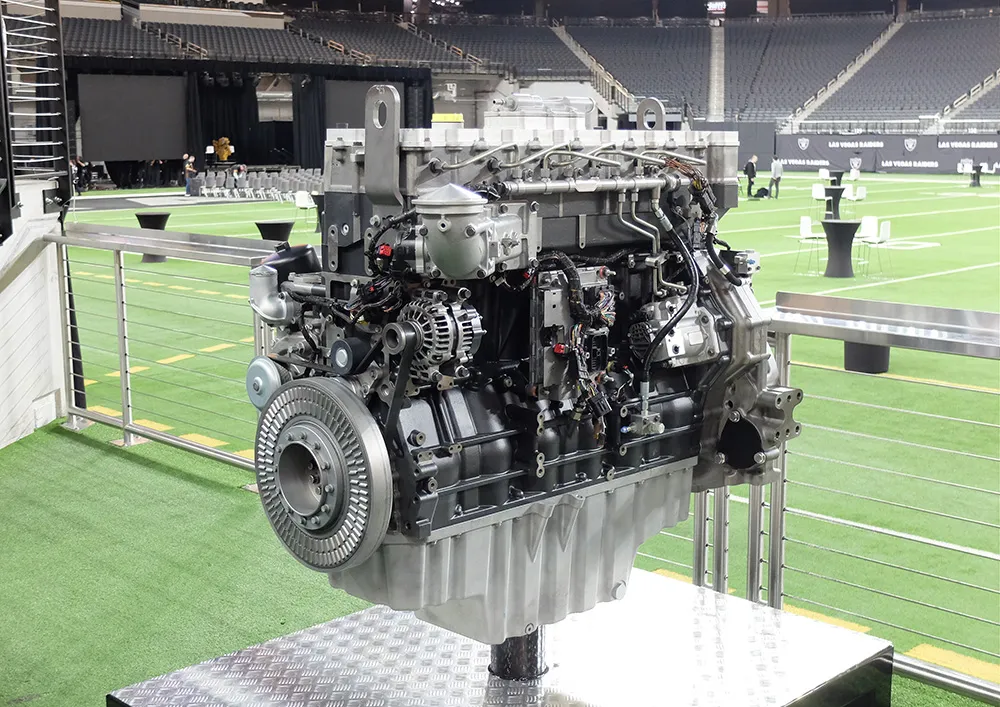

It offers a solution with a diesel engine capable of delivering high-level performance with an eye on the environment.

Soilmec says the major innovations are concentrated in the hydraulic system. In particular, the pump and distributor coupling system can manage the hydraulic oil delivery by optimising the energy demand.

This solution enables the system to operate at higher pressures and with less oil in circulation. This has also allowed for a reduction in the oil-tank capacity, resulting in a further reduction in the total cost of ownership.

Soilmec comments: “The advantages associated with the Blue Tech line remain unchanged: lower fuel consumption, quick conversion between various technologies, and more responsive and precise controls, with the possibility of customizing the control responsiveness according to the operator's preferences.”