Soilmec is offering a series of versatile new piling rigs that can handle a range of duties. The improved Blue generation range is built along modular lines. The range includes the new SR-45, SR-75, SR-95, SR-125 and DR-145 models, all of which can handle large diameter piling applications. Although the machines are being introduced, they have already been tested extensively by Soilmec’s sister company, Italian contractor Trevi. Vice president Federico Pagliacci said, “If it’s a new machine for the market i

March 14, 2016

Read time: 2 mins

The SR-45 can be specified with a short 8.5m mast for use in urban applications, allowing it to work under power lines or elevated roadways in congested city centres. And this short mast design has been proven by Trevi on a project in Manila. The short mast variant of the SR-45 can drive 2.5m diameter piles to depths of 19m, while the standard version offers maximum piling depths of 60m.

Pagliacci said that the development of this new piling rig range received assistance from Porsche Consulting, which provided expertise for design and production. The same cab design is used across the range and the larger rigs have bigger undercarriages. The new cabs offer increased visibility and comfort and are equipped with the firm’s sophisticated drilling mate system (DMS), which allows the operator to deliver high quality work consistently.

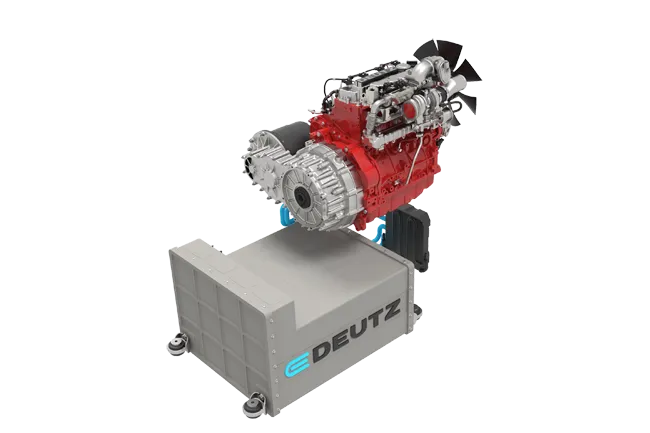

The firm says that the rigs have Tier 4 Final/Stage IV diesels as standard, although other engines can be used for less regulated markets where low sulphur fuels are not available. The new designs are more powerful as well as being more stable in operation and lighter than the models they replace.