The new 705XT track drive from

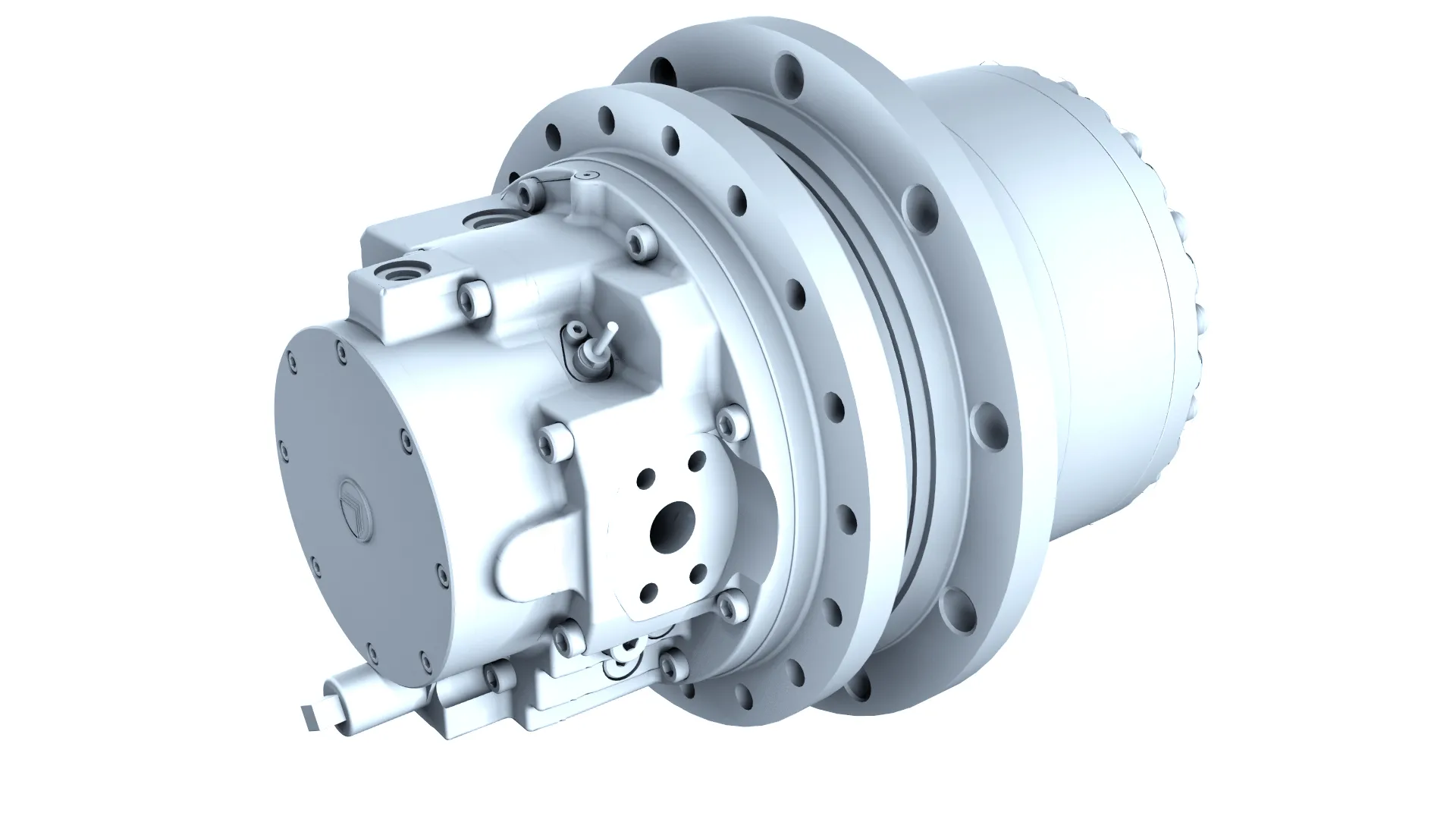

The new 705XT drive is a two-stage gearbox with an integrated swashplate hydraulic motor and parking brake, which is said to offer efficiency and compact dimensions. The integrated components allow for simplified installation, reduced overall dimensions and a cost-effective solution.

This drive unit provides an output torque of up to 17,000Nm and integrates the Th68 axial piston motor designed for a continuous pressure of 450bar and a maximum oil flow of 160litres/min.

Additional features of the 705XT drive units are the two-position hydraulic displacement control or, alternatively, an electrical proportional continuously variable displacement control and a built-in speed sensor. The 705XT track drive with integrated Th68 axial piston motor offers a cost-effective solution, according to the firm.