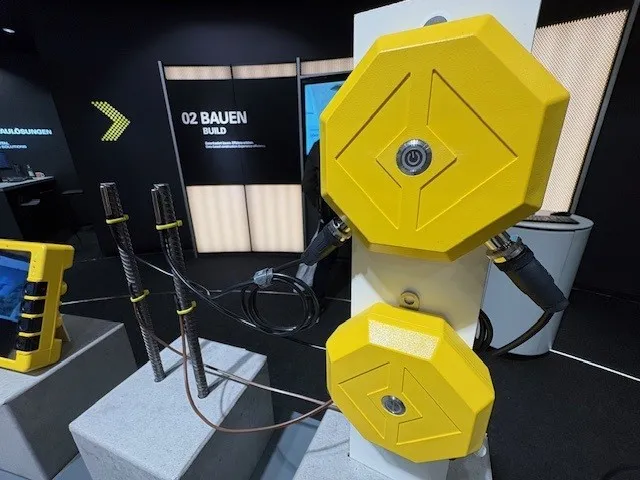

PERI subsidiary Vemaventuri says that sensor solutions can positively influence the construction process. Sensors are used to facilitate decision-making on the construction site and save resources.

Sensors can communicate the pressure exerted on the formwork during concreting as well as temperatures for determining the degree of concrete maturity to determining the water content in fresh concrete. Vemaventuri’s numerous types of sensors when combined with PERI systems offers added value.