Peri is highlighting several of its premier products this year, including the company’s panel wall formwork Maximo, its Gridflex grid slab formwork and the Peri UP Rosett Flex props.

Intermat also marks the introduction of Maximo into the French market. The product makes the best use of manpower when on-site manpower is at a premium. The one-sided tie installation by only one person reduces the time needed to set up the formwork. Ties are installed from one side without spacer tubes and there is reduced

January 6, 2017

Read time: 2 mins

INTERMAT also marks the introduction of Maximo into the French market. The product makes the best use of manpower when on-site manpower is at a premium. The one-sided tie installation by only one person reduces the time needed to set up the formwork. Ties are installed from one side without spacer tubes and there is reduced number of tie points. It offers a clean improved concrete finish thanks to neat joint and tie arrangements.

There is a minimum use of filler timbers with six panel heights from 30cm to 3m, as well as five panel widths. Maximum permissible fresh concrete pressure is 80 kN/m², while powder-coating of the elements prevents concrete adhesion and makes cleaning easier.

The German company’s Gridflex is a flexible slab formwork system with accessible girder grids. It needs very short shuttering times because of the lightweight aluminium components and pre-determined assembly sequence. Also, telescopic filler elements ensure maximum flexibility. At INTERMAT, Peri will announce a new lateral safety guardrail for Gridflex.

Peri’s UP Rosett Flex heavy-duty modular scaffolding props have a hydraulic lowering and preloading unit. The heavy-duty prop is used for the safe transfer of concentrated loads of up to 200 kN. The hydraulic cylinder in the base allows the deformation-controlled lowering of the props in 10mm increments and the torque-controlled lowering of props under load by reading off in kN on the manometer. All components can be transported by hand and by using as much as possible standard system components the solution is extremely cost-effective.

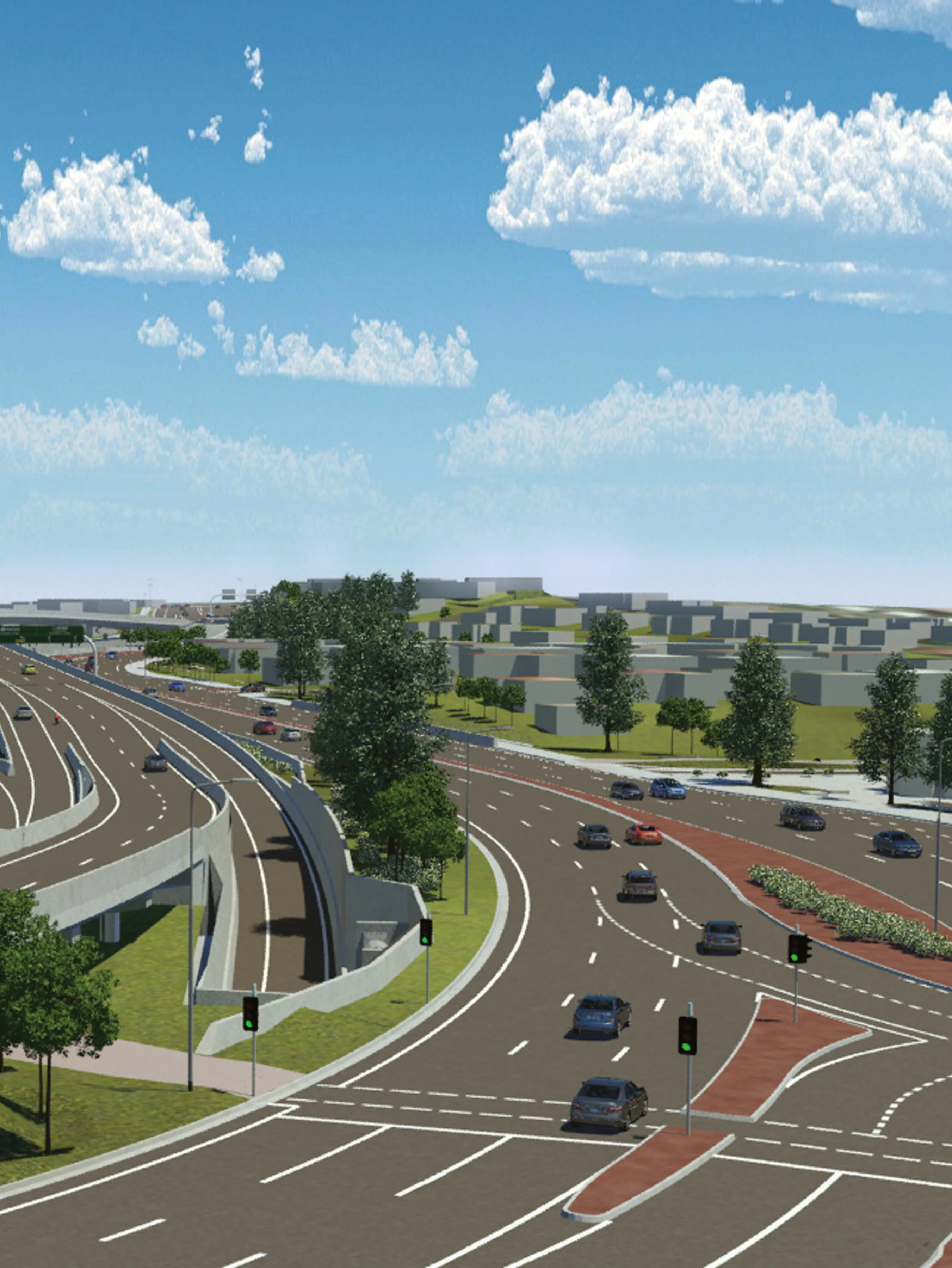

A lot of Peri formwork and scaffolding has been used on a number of major road projects throughout Europe, including the immersed four-lane Limerick Tunnel, in the republic of Ireland. The project, from 2006-2010, included pouring five tunnel elements, each about 100m long.