Among Komatsu’s stars at INTERMAT 2015 will be what the Japanese manufacturer says is its still ‘unmatched’ third generation hybrid hydraulic excavator – the HB215LC-2.

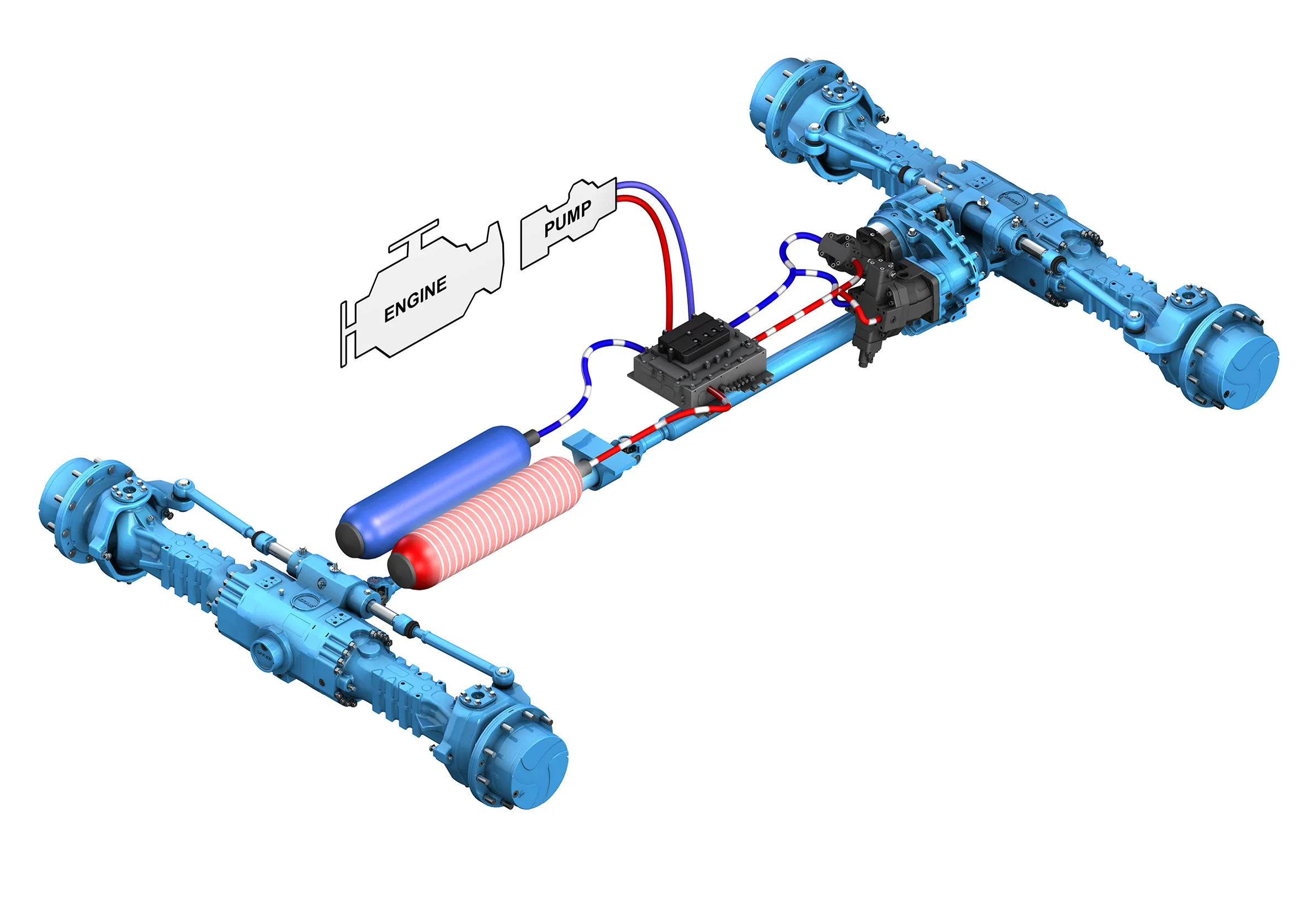

Launched in April 2014, the 22.5tonne operating weight, 1.68m³ bucket capacity HB215LC-2 is powered by the claimed revolutionary Komatsu Hybrid System, which works on the principle of swing energy regeneration and energy storage. It features Komatsu’s electric swing motor, power generator motor, ultra-capacitor and a powerful 104kW SAA4D107E-2-A diesel engine. Komatsu’s Ultra-Capacitor is said to provide fast energy and instantaneous power transmission.

The kinetic energy generated during the swing-braking phase is converted to electricity, which is sent through an inverter and captured by the Komatsu Ultra-Capacitor.

When accelerating under workload conditions the captured energy is discharged swiftly for upper structure rotation and to assist the engine as ordered by the hybrid controller. The reserve power stored by the hybrid technology represents additional horsepower that is available to maximise machine performance by supporting the engine, or is used for swing power. The HB215LC-2’s hybrid components are covered by a ‘five-year or 10,000 hours’ special warranty.

The third generation excavator is said to have been designed for easy servicing and adaptability. The HB215LC-2 includes a 50-point inspection at each service. It has two additional service valves, for use with hydraulic attachments, as standard equipment. According to Jim Venerus, deputy manager for European product marketing at