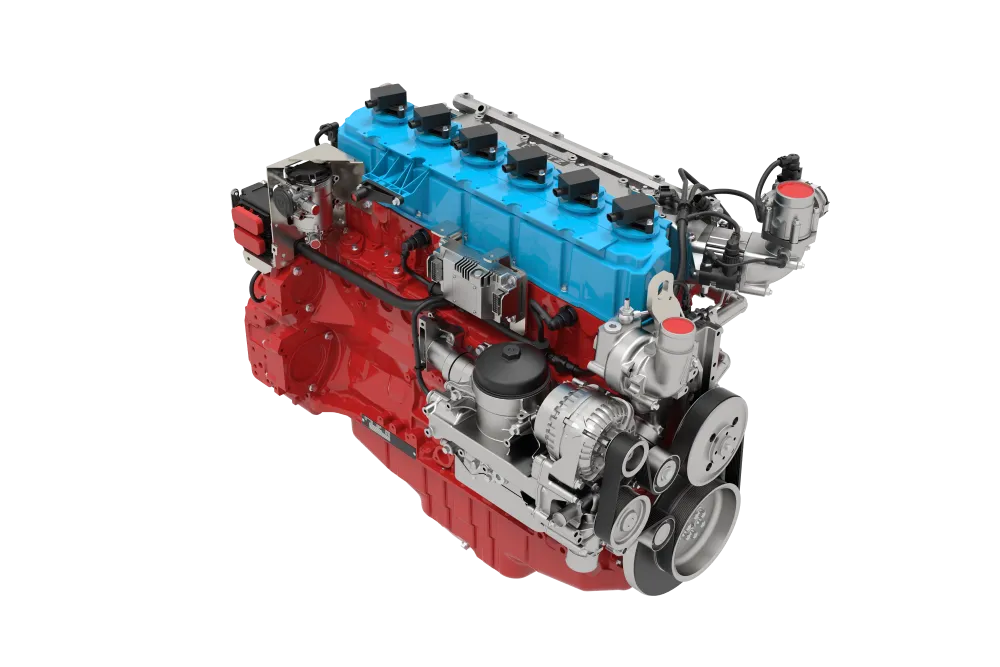

With experience gained from its construction equipment division, John Deere Power Systems is able to provide integrated solutions for OEM customers when it comes to powertrain electrification and hybrid drives.

It follows several years of field-testing and customer operation with John Deere 644K and 944K wheeled loaders, which have given the company over 200,000hours of operational time, to shorten the development processes.

With the 644K, powertrain electrification has seen the conventional torque c

April 20, 2016

Read time: 2 mins

With experience gained from its construction equipment division, 257 John Deere Power Systems is able to provide integrated solutions for OEM customers when it comes to powertrain electrification and hybrid drives.

It follows several years of field-testing and customer operation with John Deere 644K and 944K wheeled loaders, which have given the company over 200,000hours of operational time, to shorten the development processes.

With the 644K, powertrain electrification has seen the conventional torque converter and powershift transmission replaced by a motor-generator, inverter and electrically powered transmission, to connect the engine and axles. The firm’s larger 944K takes this a stage further, and uses electric wheel motors in the final drives.

“While there are potential fuel savings of around 25%, and the ability to downsize engines to achieve the same productivity, there are bigger benefits for underground mining machines,” said Darren Almond, global drivetrain business manager for John Deere Power Systems.

“We have the ability to offer power generation, power electronics and power conversion for OEM’s,” he said. “And with electric power, we can also provide a zero emissions package for underground equipment.”

It follows several years of field-testing and customer operation with John Deere 644K and 944K wheeled loaders, which have given the company over 200,000hours of operational time, to shorten the development processes.

With the 644K, powertrain electrification has seen the conventional torque converter and powershift transmission replaced by a motor-generator, inverter and electrically powered transmission, to connect the engine and axles. The firm’s larger 944K takes this a stage further, and uses electric wheel motors in the final drives.

“While there are potential fuel savings of around 25%, and the ability to downsize engines to achieve the same productivity, there are bigger benefits for underground mining machines,” said Darren Almond, global drivetrain business manager for John Deere Power Systems.

“We have the ability to offer power generation, power electronics and power conversion for OEM’s,” he said. “And with electric power, we can also provide a zero emissions package for underground equipment.”