Italian components manufacturer Comer Industries says its investment in homeland manufacturing and assembly line facilities, along with its updating of product lines, has left it well placed to benefit from construction sector growth forecast by many of its customers.

A new, fully automated axle assembly line for the S-128, and S-228-238 steering and rigid axle generations at the Planetary Drives and Axles plant in Cavriago, near Reggio Emilia, Italy, went live in May this year. This followed last year’s

January 9, 2015

Read time: 3 mins

Italian components manufacturer Comer Industries says its investment in homeland manufacturing and assembly line facilities, along with its updating of product lines, has left it well placed to benefit from construction sector growth forecast by many of its customers.

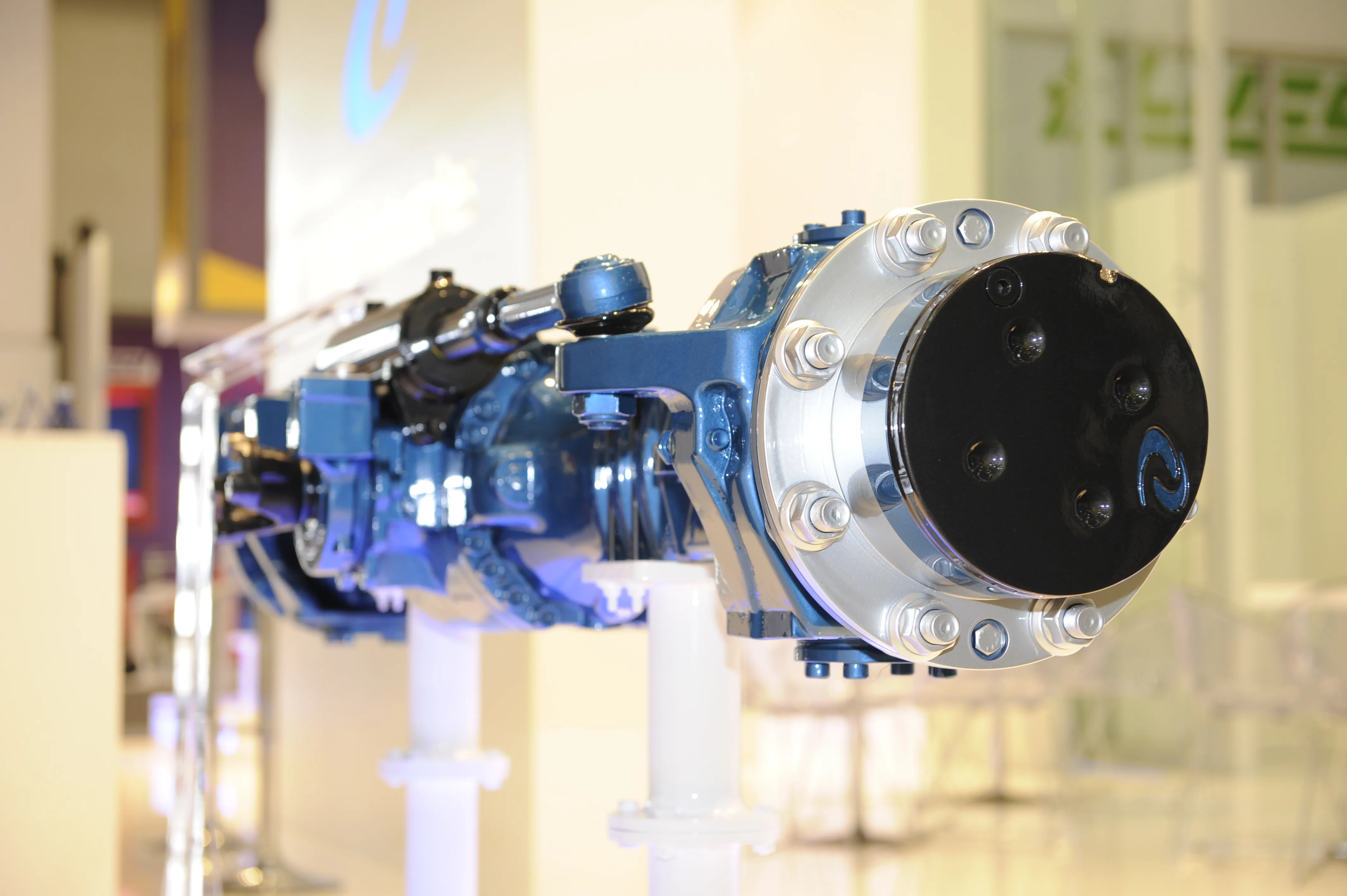

A new, fully automated axle assembly line for the S-128, and S-228-238 steering and rigid axle generations at the Planetary Drives and Axles plant in Cavriago, near Reggio Emilia, Italy, went live in May this year. This followed last year’s opening of a new gearbox manufacturing plant in Reggiolo, and the significant expansion of the existing gearbox and axle manufacturing facility in Mantera.7292 Comer Industries has also invested substantially in its gearbox assembly plant in China, and component assembly facility in Brazil.

The firm’s large range of components, which also includes PTO driveshafts, speed increasers and reducers, slew drives, orbit motors, and control systems for hydrostatic transmissions and electronic control devices, are fitted in wheeled loaders, excavators, pavers, telehandlers, cranes and other equipment model lines of leading OEMS such as718 Liebherr, 178 Caterpillar, 257 John Deere, 1222 Terex, 176 Case, 5895 New Holland and 1170 Sany.

A spokesperson for the company said its Industrial & Energy sector trading had grown by 20% in the past 12 months, and with growing customer demand for customised components in key markets including Europe, such growth is likely to continue over the next few years.

“In a flat market we are growing significantly because of our investments in production and our customers,” said the spokesperson, and that in many cases Comer Industries is now able to source and fit replacement components for customers within 24 hours. “What we have also done in the past years is get ready for the construction sector growth that our customers say is coming,” he added.

During a visit by World Highways to the state-of-the-art Cavriago assembly plant, the spokesperson stressed how each of the firm’s new component lines are field tested and perfected for around two years prior to going into full scale production. The spokesperson also highlighted how Comer Industries follows the Comer Business System (CBS), aimed at encouraging innovation and continuous improvement in the company’s processes to benefit the customer while, at the same time, developing staff talent. The CBS system is applied by EFQM (European Foundation for Quality Management).

The impressive new automated axle assembly line at Comer Industries’ Cavriago plant comes with the vital benefit of full traceability of all assembled components and sub-phases, a requirement from both Internal Process Failure Mode Effects Analysis (PFMEA) and from leading OEMs.

Among the top OEM equipment models being fitted with the Cavriago-assembled S-128 axles are Liebherr’s L506 and L508 compact wheeled loaders, launched at the688 bauma 2013 exhibition in Munich, Germany.

Comer Industries says the S-128 axle has been upgraded with new features such as oil-immersed disc brakes said to arranged in a highly efficient configuration. Fitted with an eight-stud wheel hub as standard, the S-128 axle is also available with a six-stud wheel hub, making it mountable on smaller tyres.

A new, fully automated axle assembly line for the S-128, and S-228-238 steering and rigid axle generations at the Planetary Drives and Axles plant in Cavriago, near Reggio Emilia, Italy, went live in May this year. This followed last year’s opening of a new gearbox manufacturing plant in Reggiolo, and the significant expansion of the existing gearbox and axle manufacturing facility in Mantera.

The firm’s large range of components, which also includes PTO driveshafts, speed increasers and reducers, slew drives, orbit motors, and control systems for hydrostatic transmissions and electronic control devices, are fitted in wheeled loaders, excavators, pavers, telehandlers, cranes and other equipment model lines of leading OEMS such as

A spokesperson for the company said its Industrial & Energy sector trading had grown by 20% in the past 12 months, and with growing customer demand for customised components in key markets including Europe, such growth is likely to continue over the next few years.

“In a flat market we are growing significantly because of our investments in production and our customers,” said the spokesperson, and that in many cases Comer Industries is now able to source and fit replacement components for customers within 24 hours. “What we have also done in the past years is get ready for the construction sector growth that our customers say is coming,” he added.

During a visit by World Highways to the state-of-the-art Cavriago assembly plant, the spokesperson stressed how each of the firm’s new component lines are field tested and perfected for around two years prior to going into full scale production. The spokesperson also highlighted how Comer Industries follows the Comer Business System (CBS), aimed at encouraging innovation and continuous improvement in the company’s processes to benefit the customer while, at the same time, developing staff talent. The CBS system is applied by EFQM (European Foundation for Quality Management).

The impressive new automated axle assembly line at Comer Industries’ Cavriago plant comes with the vital benefit of full traceability of all assembled components and sub-phases, a requirement from both Internal Process Failure Mode Effects Analysis (PFMEA) and from leading OEMs.

Among the top OEM equipment models being fitted with the Cavriago-assembled S-128 axles are Liebherr’s L506 and L508 compact wheeled loaders, launched at the

Comer Industries says the S-128 axle has been upgraded with new features such as oil-immersed disc brakes said to arranged in a highly efficient configuration. Fitted with an eight-stud wheel hub as standard, the S-128 axle is also available with a six-stud wheel hub, making it mountable on smaller tyres.