A number of

Launched in December 2014, a total of six models ranging from 24-40tonnes are part of the overall new crawler excavator line-up.

The 25tonne DX255LC-5 can be used for diverse applications including clearing land for initial site development, excavating for foundations and trenching for utilities, and for earthmoving and maintenance work for highway, civil engineering and general construction projects. Whilst overall dimensions are similar to the previous DX255LC-5 model, the Stage IV version is said to combine greater power with a 500kg increase in operating weight, resulting in claimed increases of up to 17% in lifting capacities over both the front and side and a 1 dBA reduction in sound levels.

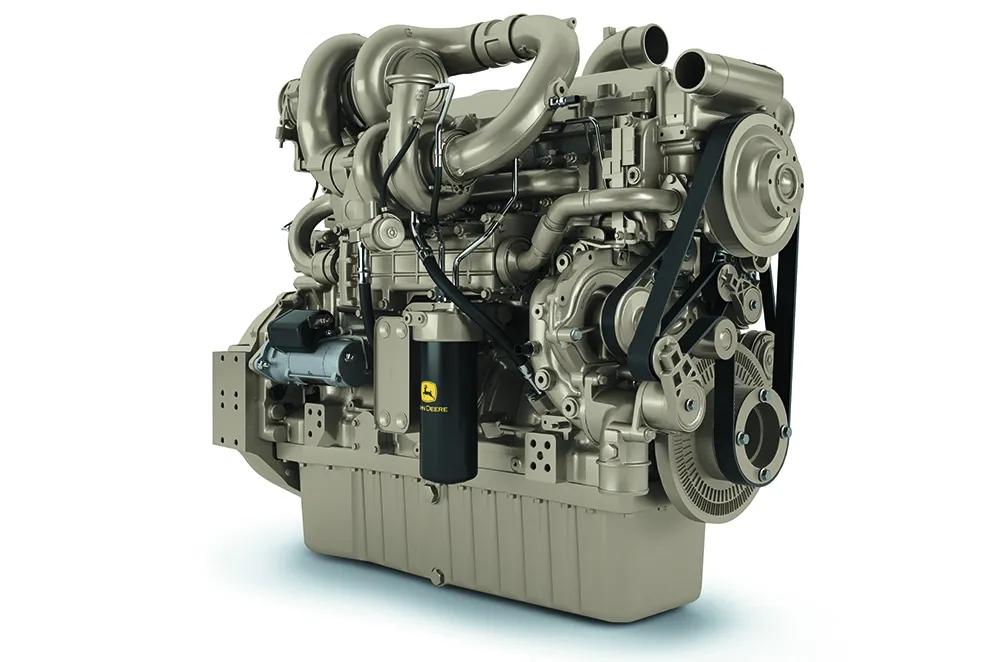

A Doosan DLO6P six-cylinder, turbocharged engine on the DX255LC-5 is said to offer 5% more engine power than its previous generation LC-3 model, with the new Stage IV crawler excavator also offering an average fuel consumption reduction of 4% to 9% on the DX255LC-3.

Like all Doosan’s other Stage IV/Tier 4 Final crawler excavators, the DX255LC-5 is fitted with the new state-of-the-art CoreTMS wireless fleet monitoring system as standard. Designed specifically for the Doosan range, the system provides thorough information about machine performance in a dual mode (satellite, GSM). As the software in the Core TMS has been upgraded to communicate directly with the EPOS system on a Doosan excavator, it is said to be the only tool of its type capable of providing customers with this level of insightful, cost-saving data.

The six new Doosan models in the 24-40tonne operating weight range are the DX235LCR-5, DX235NLC-5, DX255LC-5, DX300LC-5, DXC340LC-5, and the DX380LC-5.

Doosan new high performing crawler excavators on show

A number of Doosan’s wide range of new Stage IV/Tier 4 Final crawler excavators are new from the firm.

January 6, 2017

Read time: 2 mins