“In the last few years, Doka has become well-known in the residential sector in France. Now we want to show that we are experts in infrastructure as well,” says Doka France’s head of product management and marketing, Oscar Castilla.

The tunnel formwork, SL1, used to form the crown of a tunnel, has recently been modified so that the face-forming element is steel rather than timber. “This means that it is more durable and therefore for a long tunnel, it makes it cheaper” says Castilla. “The second advantage is that the whole thing can be rented.”

Also on display was Doka’s STAXO 100 load-bearing tower which also boasted a modification. It now includes aluminium beams to transfer load from the structure to the tower where previously timber beams were used. This allows a capacity of the tower of 10 tonnes per leg with lightweight beams that can be assembled by hand. Doka has already secured projects on the Grand Paris programme with this product, says Castilla.

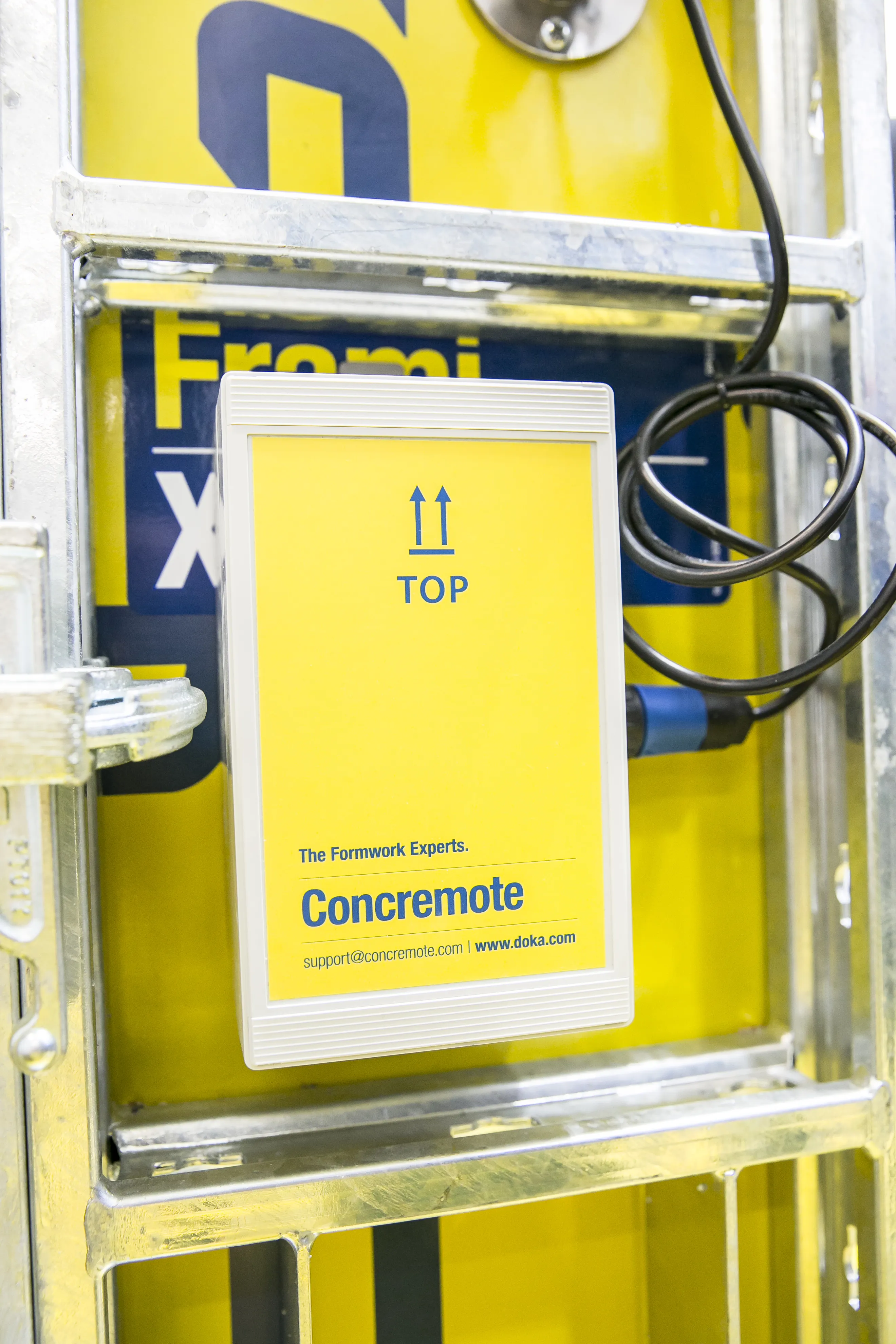

Doka’s remote concrete monitoring technology, Concremote, is also new to the French market, says Castilla, and is being deployed in several projects for the first time now. Concremote measures the strength of the concrete in real time, through monitoring the heat, which means that formwork can be struck as soon as the required strength is reached, increasing productivity and ensuring quality and safety.