“Cummins will be investing $300million over the next three years to continue organic and inorganic growth to develop a portfolio of alternative power units for the off-highway market including full electric vehicles, range-extended vehicles and plug-in hybrids,” said Julie Furber, executive director of Cummins’ electrified power business.

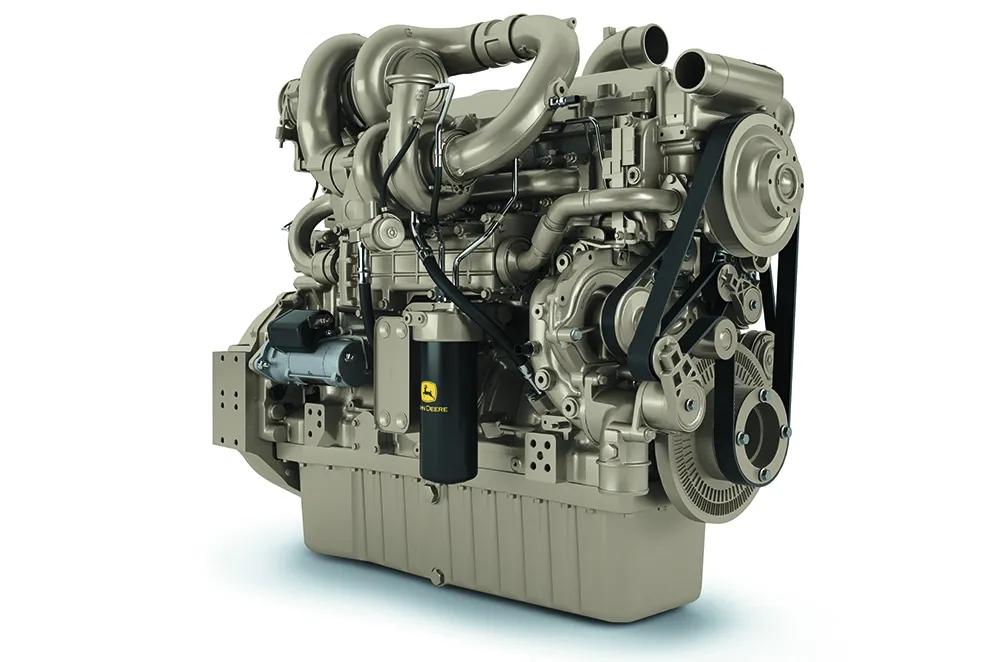

The REEV concept comprises a four-cylinder F3.8 stage V-compliant diesel engine, a battery pack, power electronics and a high-efficiency traction motor. In principle, the battery pack provides an electrical power source for the traction motor to run a vehicle’s transmission, with battery energy replenished by the diesel engine.

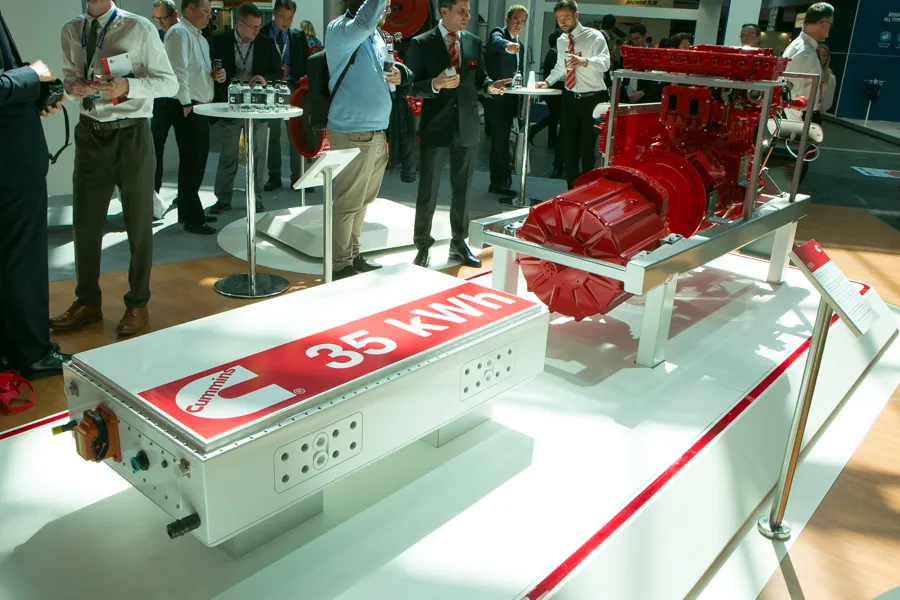

Battery packs offer 35kWh of power and are modular, enabling packs to be linked according to the application.

“The REEV concept allows the battery packs to be charged as overnight, using a plug-in electricity supply, with the engine topping-up as a generator during the working day,” said Furber. “A 35kWh battery pack should give two hours of 100% electric operation, and once the charge drops to 30%, the engine will automatically start and introduce a charge to keep the vehicle working.”

The REEV concept could easily replace a traditional power source that currently relies on a 9litre diesel engine, she concluded.