Possibly the oldest company at INTERMAT - pewag, whose origins date back to 1479 - showed new chain link designs for its range of tyre protection products and new vertical lifting clamps.

The pewag tycoon ultra-resistant link now features a wider design for greater stability and longer life due to a greater wear surface. The design also reduces the movement between link and ring which contributes to increased lifetime. The tycoon link is aimed at giant wheel loaders and operations in the most abrasive har

January 6, 2017

Read time: 2 mins

Possibly the oldest company at INTERMAT - 8072 pewag, whose origins date back to 1479 - showed new chain link designs for its range of tyre protection products and new vertical lifting clamps.

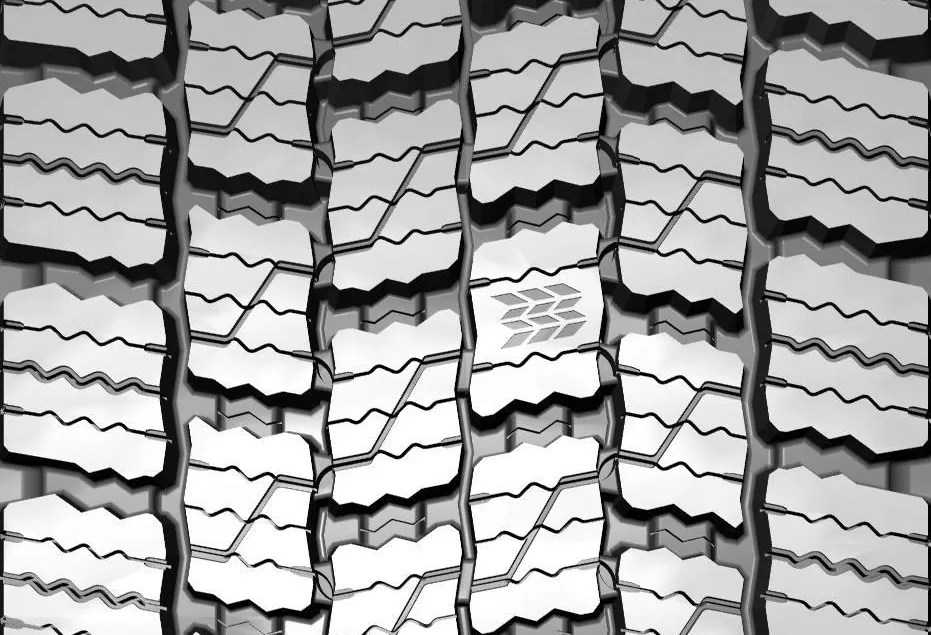

The pewag tycoon ultra-resistant link now features a wider design for greater stability and longer life due to a greater wear surface. The design also reduces the movement between link and ring which contributes to increased lifetime. The tycoon link is aimed at giant wheel loaders and operations in the most abrasive hard rock conditions.

The firm also showed samples of a new chain link it has under development for snow applications. The link has a flat surface on its interior and a round surface on the exterior that prevents chains made with the links from twisting on the tyres to which they are fitted. The new design improves efficiency and durability of chains, says Jean-Marie Monat, commercial manager for pewag France. Also, the grip element of the link now has indentations that provide more surface area to give 7% longer life than previous designs. The links will be available on pewag’s range of snow application chains for winter 2015, says Monat.

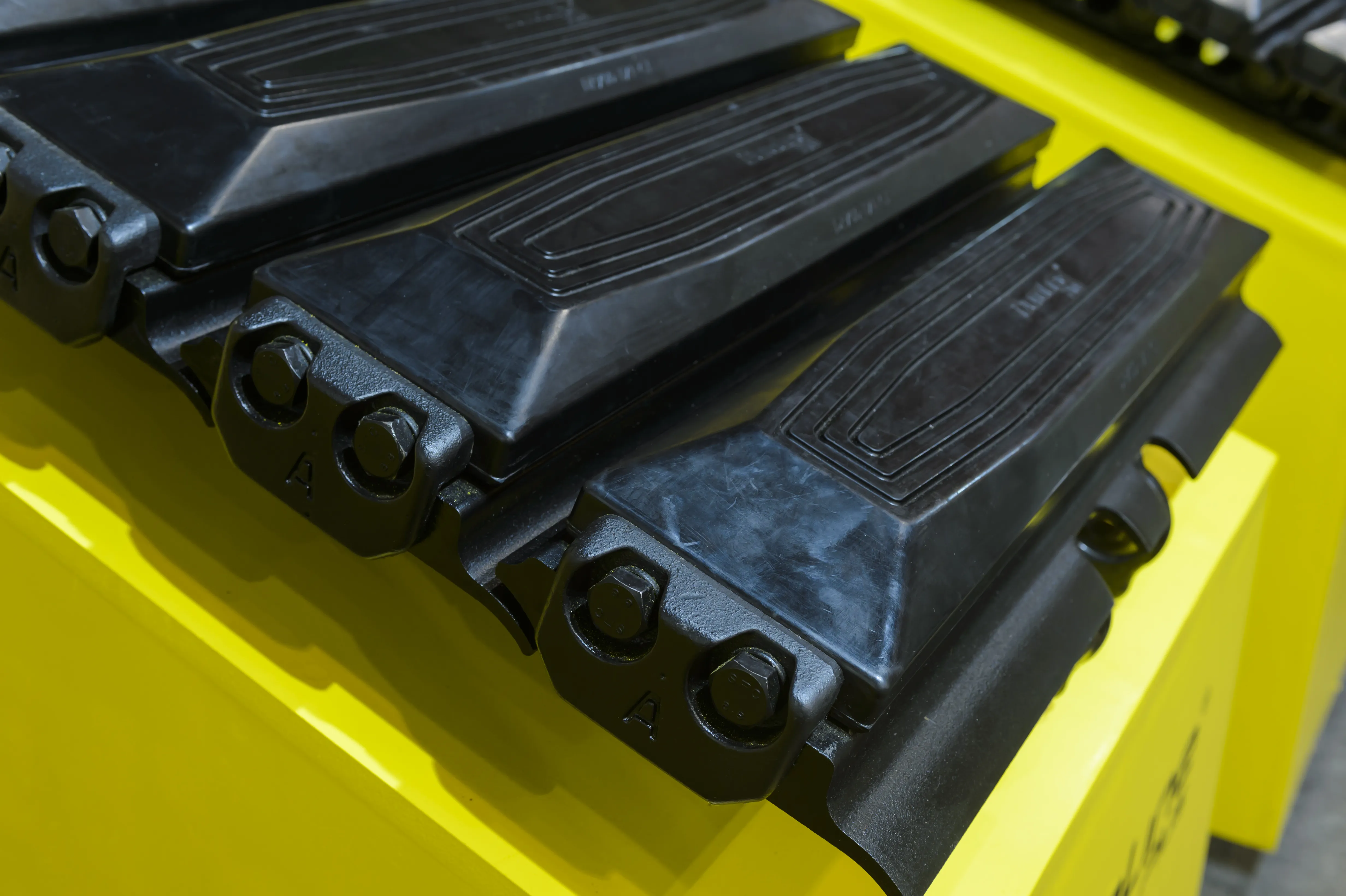

The company is also planning to introduce a new range of chain tracks for forestry applications in September 2015.

The pewag winner vertical lifting clamps are designed for lifting and moving steel beams, profiles and structures where the load must stay in position. The special shape of the lifting shackle places the centre of the gravity of the beam beneath the lifting shackle. This maintains the equilibrium of the beam once it has been lifted and keeps the flanges vertical so that the beam can easily be stacked or positioned.

The pewag tycoon ultra-resistant link now features a wider design for greater stability and longer life due to a greater wear surface. The design also reduces the movement between link and ring which contributes to increased lifetime. The tycoon link is aimed at giant wheel loaders and operations in the most abrasive hard rock conditions.

The firm also showed samples of a new chain link it has under development for snow applications. The link has a flat surface on its interior and a round surface on the exterior that prevents chains made with the links from twisting on the tyres to which they are fitted. The new design improves efficiency and durability of chains, says Jean-Marie Monat, commercial manager for pewag France. Also, the grip element of the link now has indentations that provide more surface area to give 7% longer life than previous designs. The links will be available on pewag’s range of snow application chains for winter 2015, says Monat.

The company is also planning to introduce a new range of chain tracks for forestry applications in September 2015.

The pewag winner vertical lifting clamps are designed for lifting and moving steel beams, profiles and structures where the load must stay in position. The special shape of the lifting shackle places the centre of the gravity of the beam beneath the lifting shackle. This maintains the equilibrium of the beam once it has been lifted and keeps the flanges vertical so that the beam can easily be stacked or positioned.