The type ECO asphalt mixing plant range offers outputs from 100tonnes/hour to 320tonnes/hour to ensure maximum mobility and flexibility.

The machines can be operated as stationary plant but the can also handle fast location changes without problems, according to Benninghoven.

Benninghoven has always relied on loading skip technology as the link between mixer and loading silo. When working like this, the skip volume corresponds to the volume of the mixer.

In essence, the mixer drains the asphalt vertically downwards into the skip. The skip then positions itself vertically above the targeted loading silo pocket and again drains the stored mix vertically downwards … this is a proven technology for excluding segregations in the mix.

The new alternating chute unit is, because it is a purely mechanical structure, less likely to malfunction. There are no sensor systems, motors and brakes and there is also a fast and load-free positioning for silo selection.

Also, separation in the end-product is minimised through active cross-mixing in the material transfer. The geometry of the mixed materials storage silos ensures mass flow instead of core flow, which also prevents segregation in the mix.

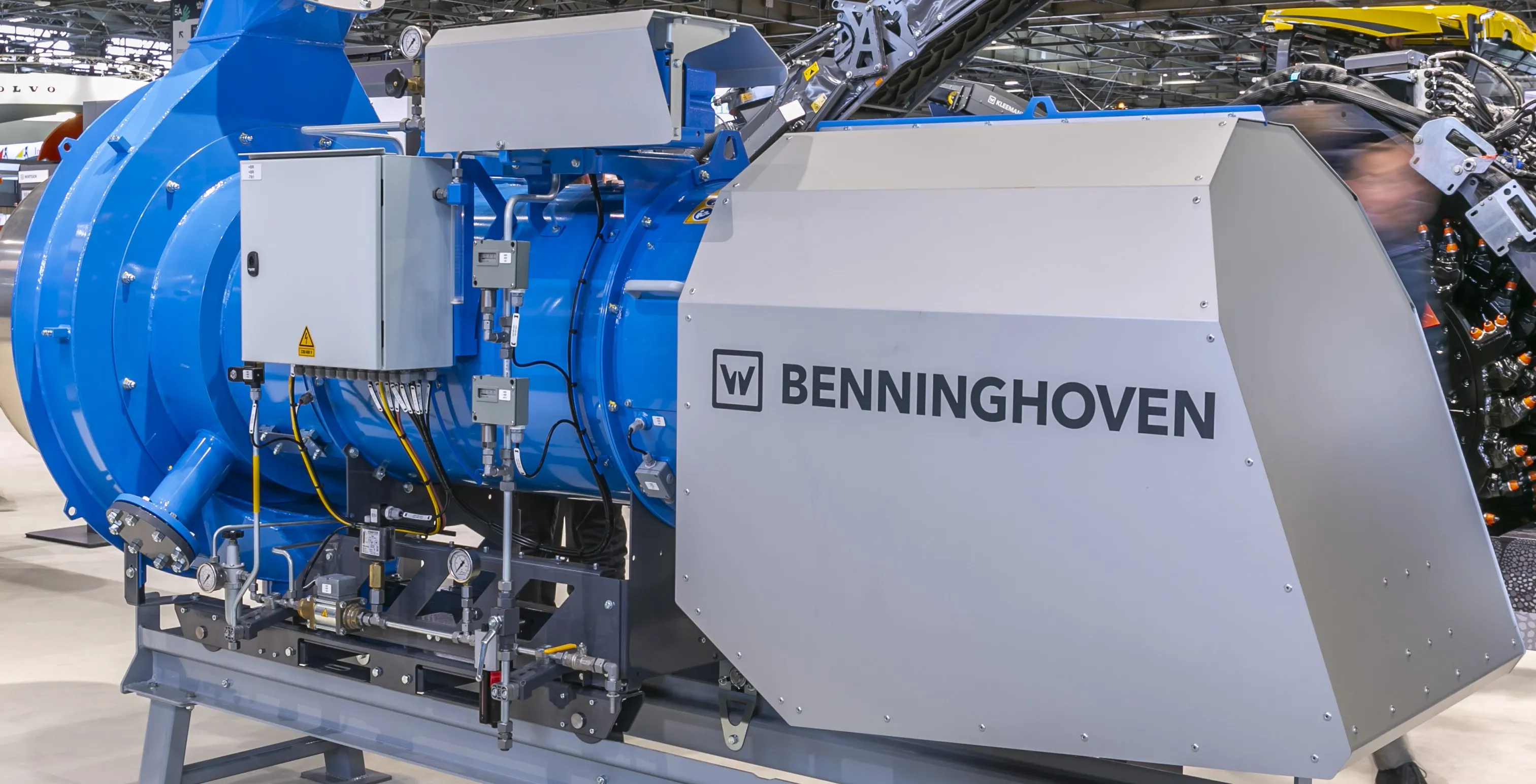

There is also a large service opening on the mixer cabinet. It is 600mm high and 1,200mm wide.