DEUTZ is exhibiting new products at Bauma China 2014, being launched together with its Chinese joint venture DEUTZ (Dalian) Engine (DDE). The partners are launching engines designed to comply with the new third Chinese emissions standard (China Stage III), which comes into effect in October 2015 and is the equivalent of the EU Stage IIIA.

A key product being introduced is the TCD 2013 L6 2V, which offers power outputs of up to 200kW and torque of up to 1,100Nm. This engine suits use in 5tonne capacity whe

November 21, 2014

Read time: 2 mins

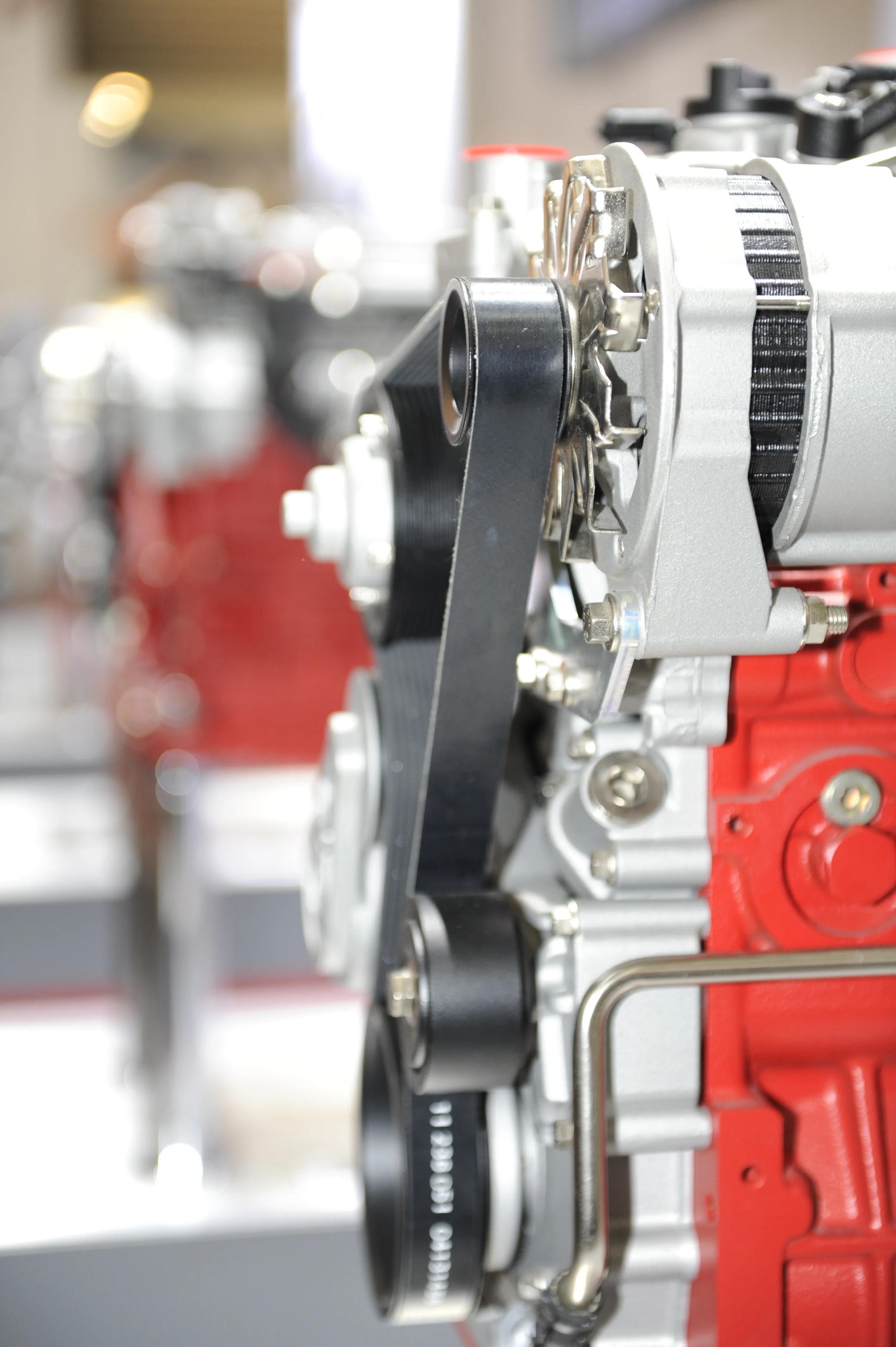

A key product being introduced is the TCD 2013 L6 2V, which offers power outputs of up to 200kW and torque of up to 1,100Nm. This engine suits use in 5tonne capacity wheeled loaders as well as excavators. The diesel feature an advanced DEUTZ common-rail (DCR) fuel injection system and electronic engine control (EMR 3). As a result it is said to be highly efficient, achieving a rate of 205grammes of fuel/kWh.

DEUTZ is introducing engines for compact applications, including the D 2011 L4i used in small construction equipment and compressors. It delivers 46kW and a torque of 190Nm, with a key feature being its integrated cooling system with no front-end radiator that makes installation easier and saves space. DEUTZ is also offering the latest TCD 2.9 L4 and TCD 7.8 L6; two advanced engines that comply with EU Stage IV. The modular DVERT exhaust aftertreatment system is fitted and DEUTZ is highlighting the diesel particulate filter (DPF) and selective catalytic reduction (SCR). The fourth emissions standard in China that will use such technology is not expected until after 2020 so the systems by then will be well-proven.