The new Marini Evodryer Plus plant is said to offer customers a sophisticated plant capable of handling high percentages of up to 70% RAP in the feed, while featuring just one drum. This slots into the range between the more complex and costly parallel drum plants able to handle up to 80% RAP in the feed, and the simpler existing units with just one drum that can handle up to 60% RAP in the feed.

The key to the plant is the way the hot gas generator is integrated into the single drum. “It’s a completely different concept,” said a company spokesperson.

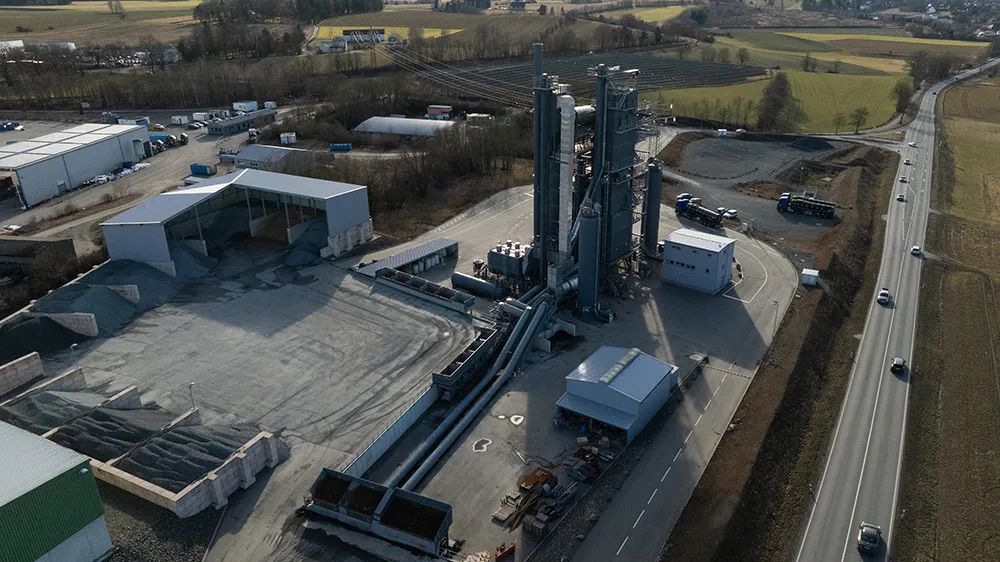

The firm moved the dryer from the ground to the top of the plant as this eliminates the risk of the potentially sticky RAP material causing problems in an elevator. The design also reduces thermal dispersion.

Meanwhile, the drum has been extended by 3m and two small burners have been added, firing the hot gas generator. This patented design heats the materials in the drum efficiently but without the risk of overheating. Meanwhile the discharge system features insulated hoppers to prevent sticking when there is a high percentage of RAP in the mix.

The firm says that this advanced asphalt production system allows up to 70% RAP usage but without compromising on product quality. The plant suits medium-large production volumes with high RAP content but with just one drum, the plant is less costly to buy, has lower fuel costs and is simpler to maintain than sophisticated parallel drum plants.