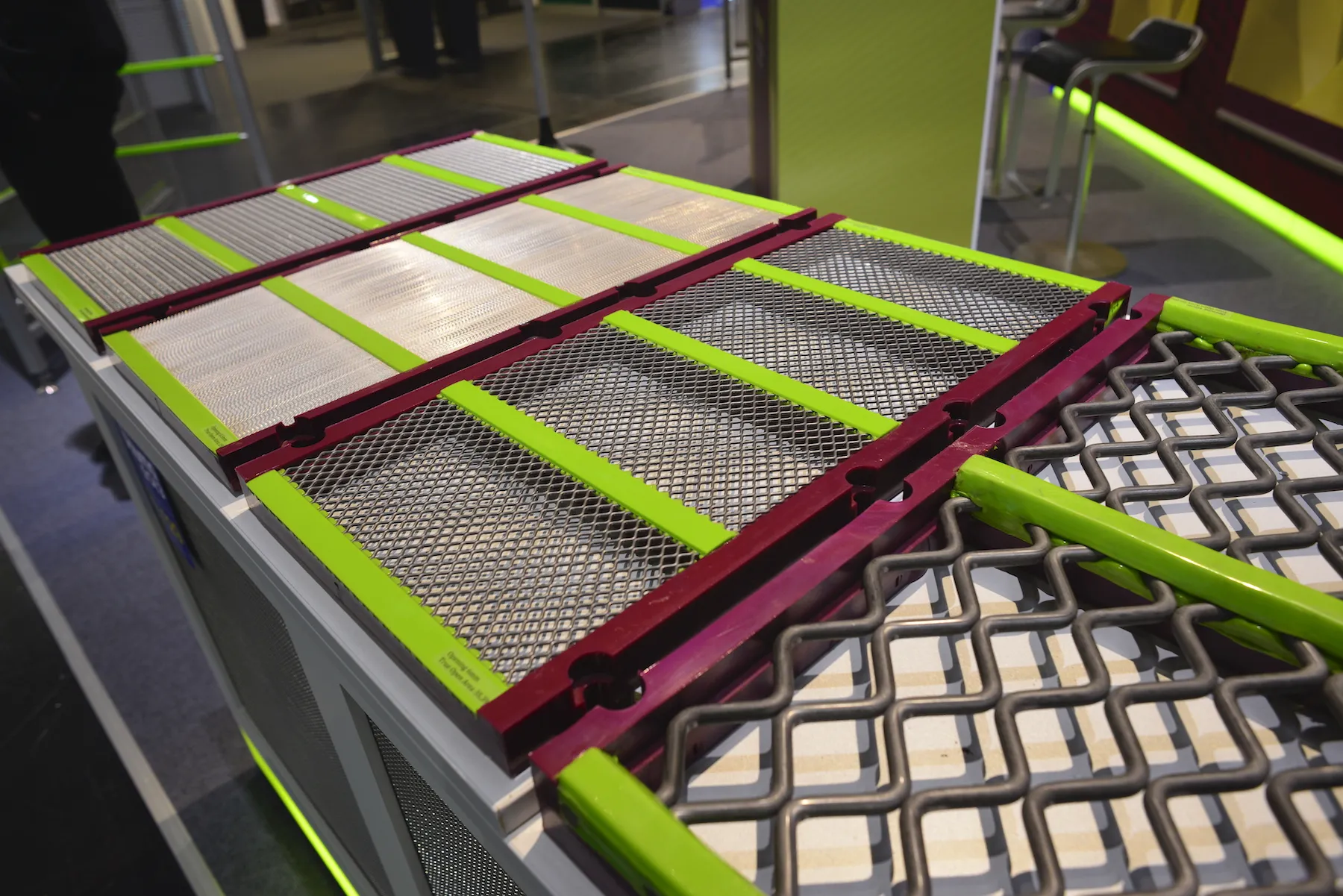

NLMK Clabecq, the Belgian plate division of Russian steel giant NLMK Group, is benefitting from a €100m investment in its quenching and tempering operation, with the introduction of additional Quard abrasion-resistant steels and Quend high-yield strength steel plate.

January 6, 2017

Read time: 2 mins

The company, which specialises in thin rolled plate, is introducing Quard 500 this year, a 500 Brinell strength steel that should prove particularly popular with mining and crushing equipment manufacturers. NLMK will also launch a Quard 550 steel in 2014.

“Quard 500 is the product that we have been missing to break into the mining sector,” said Bernard Robins, marketing manager. “We also see a move for several customers to replace Quard 400 with a 500 Brinell steel plate.”

In addition, the firm is to offer Quard 900 and 960 this year – high strength steels that are used in crane boom construction. Next year the company will add Quard 1100 and Quard 1300 to its product line. The company is also broadening the range of steel plate on offer, taking thickness down from a minimum 4mm to just 3mm thick, while at the opposite end of the spectrum offering a 40mm thick plate for the first time.

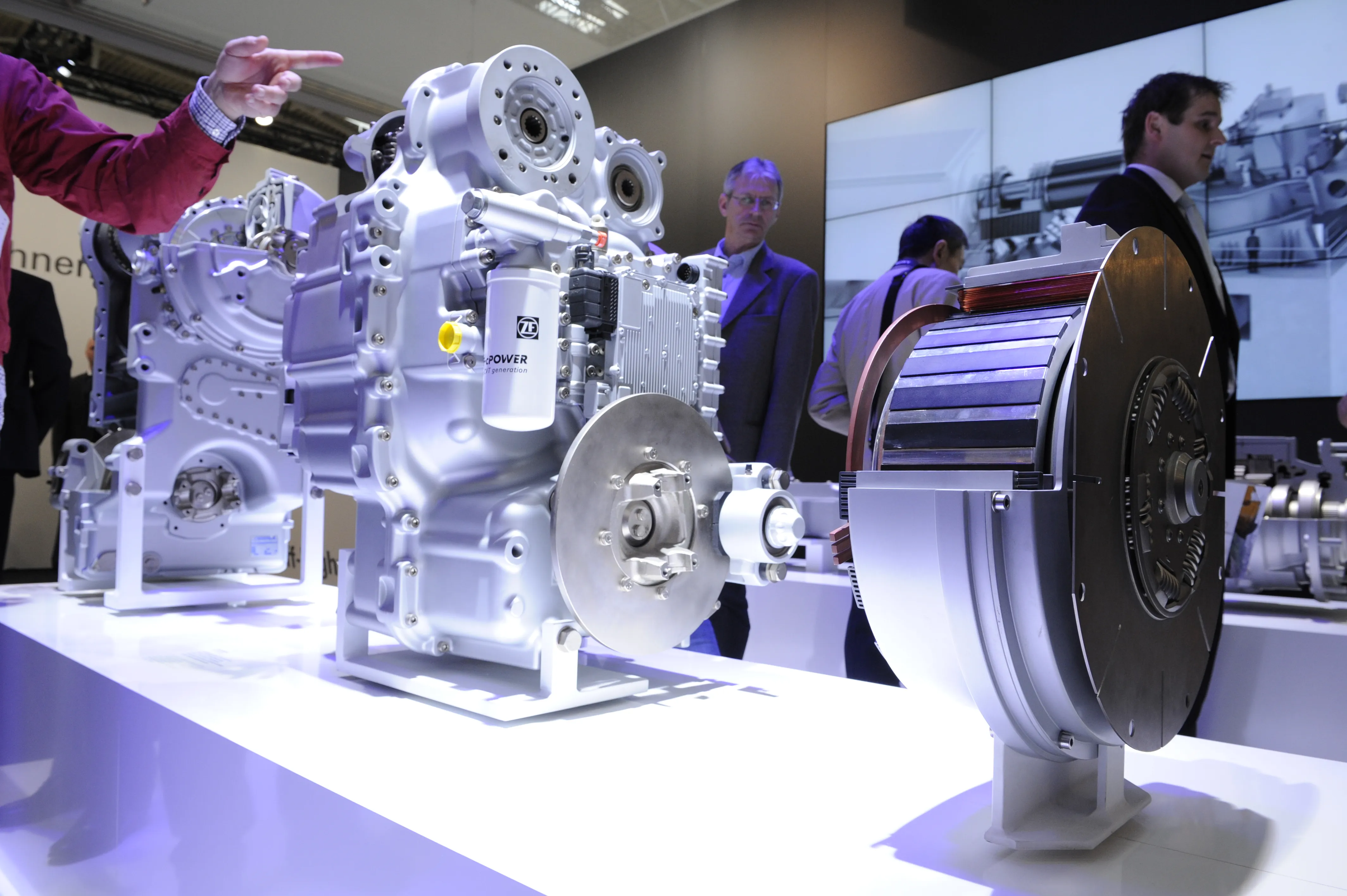

Clabecq’s high-accuracy rolling makes fabrication easier for machinery manufacturers with clean, consistent thin plate allowing designers to reduce steel content and weight in machines, cutting fuel consumption. The company lists manufacturers such as

%$Linker: