The Allu 3D Positioning System will make ground stabilisation works more efficient and more cost-effective, according to the Finnish manufacturer. The GPS-guided system works in conjunction with Allu’s PMX mixing head, which is mounted on an excavator. It is made up from four modules – computer unit with software, touch screen, base station and GPS antennas positioned on the mixing unit. Often used in road construction to firm up soft ground, the ground stabilisation process sees the binder material fed in

April 19, 2013

Read time: 2 mins

The 2180 ALLU 3D Positioning System will make ground stabilisation works more efficient and more cost-effective, according to the Finnish manufacturer.

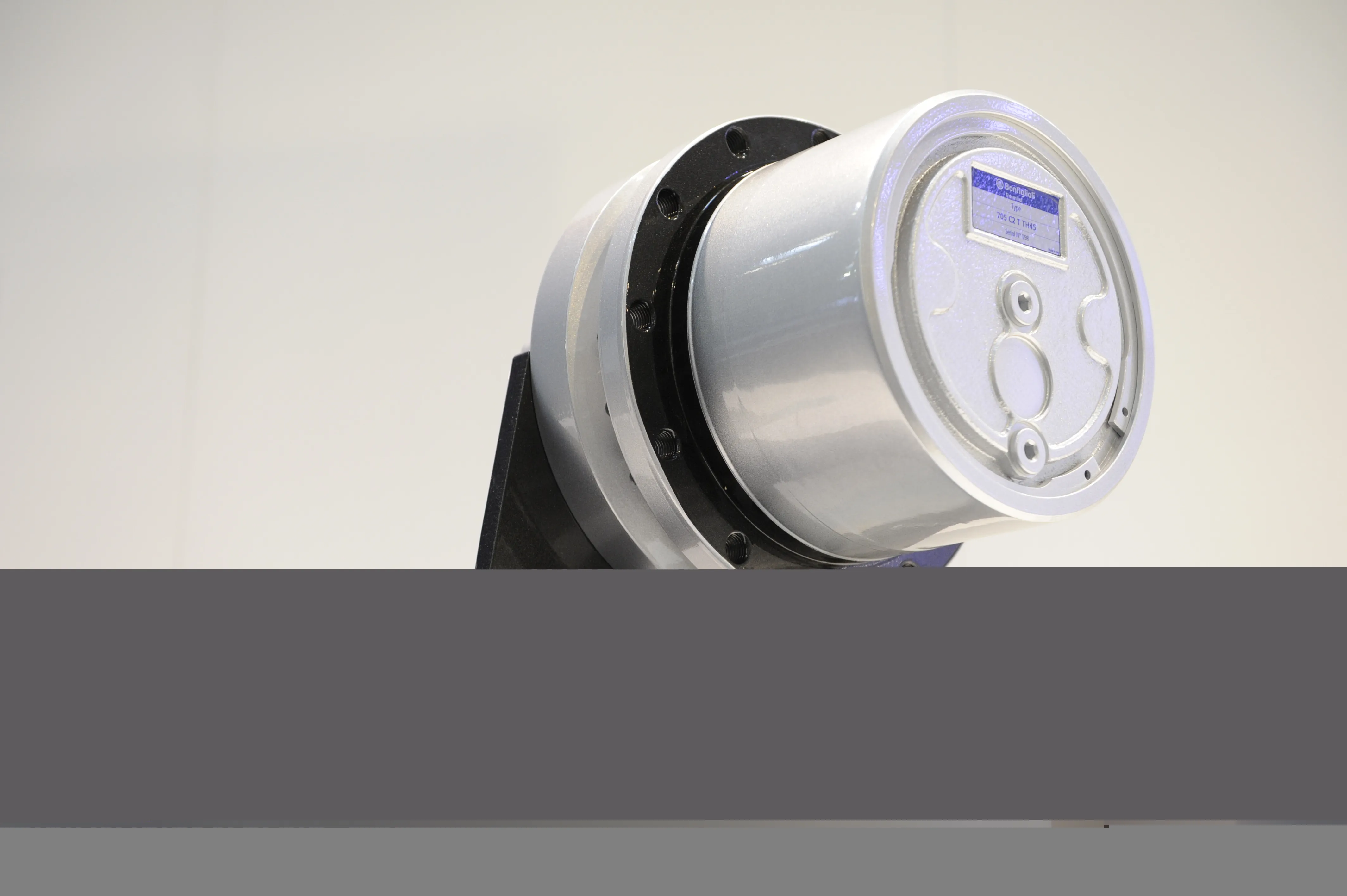

The GPS-guided system works in conjunction with Allu’s PMX mixing head, which is mounted on an excavator. It is made up from four modules – computer unit with software, touch screen, base station and GPS antennas positioned on the mixing unit.

Often used in road construction to firm up soft ground, the ground stabilisation process sees the binder material fed in powder form via a hose to the mixing head where it is churned into the soil.

The Allu 3D Positioning System tells the driver where to position the mixing head and, when the area of ground being stabilised is complete, it tells the driver to change location. “This eases the mixing work and at the same time ensures homogenous mixing results and accurate binder feeding on each cell,” said Allu.

The advantage for the contractor is that it makes binder use more efficient, saving money, and also saving time. The system also records the ground stabilisation information for each cell, information which can be transferred via a memory stick and used by the contractor for reporting and planning.2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

The GPS-guided system works in conjunction with Allu’s PMX mixing head, which is mounted on an excavator. It is made up from four modules – computer unit with software, touch screen, base station and GPS antennas positioned on the mixing unit.

Often used in road construction to firm up soft ground, the ground stabilisation process sees the binder material fed in powder form via a hose to the mixing head where it is churned into the soil.

The Allu 3D Positioning System tells the driver where to position the mixing head and, when the area of ground being stabilised is complete, it tells the driver to change location. “This eases the mixing work and at the same time ensures homogenous mixing results and accurate binder feeding on each cell,” said Allu.

The advantage for the contractor is that it makes binder use more efficient, saving money, and also saving time. The system also records the ground stabilisation information for each cell, information which can be transferred via a memory stick and used by the contractor for reporting and planning.

Stand: FGN.N718/2

%$Linker: