From mixing plant to compaction, the temperature of asphalt is critical. Cold asphalt can lead to road damages, which result in additional costs of up to 46% due a shorter lifetime of the road. With optimum composition of both asphalt material and process flow being priorities in the road construction process, the new MOBA PAVE-IR temperature scanner system enhances both.

January 6, 2017

Read time: 2 mins

From mixing plant to compaction, the temperature of asphalt is critical. Cold asphalt can lead to road damages, which result in additional costs of up to 46% due a shorter lifetime of the road.

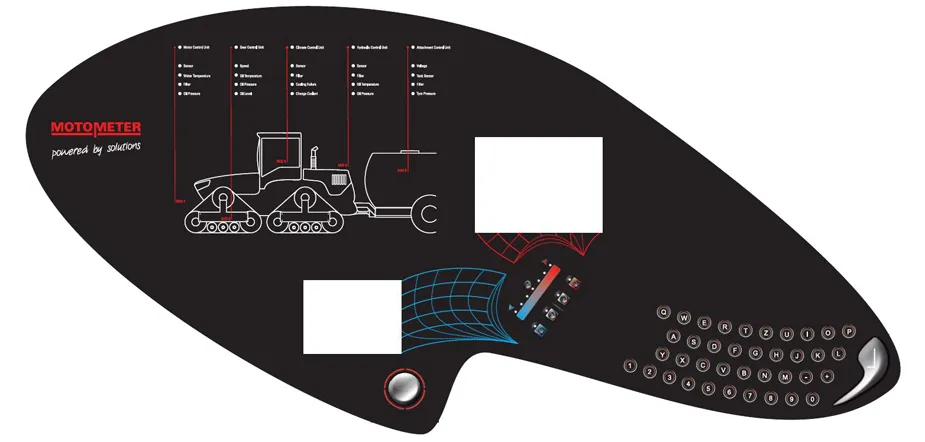

With optimum composition of both asphalt material and process flow being priorities in the road construction process, the new1228 MOBA PAVE-IR temperature scanner system enhances both.

The MOBA PAVE-IR system features a high-speed scanner to monitor the temperature during asphalt paving and document it for the entire project. As a result, contractors can optimise their processes and verify the quality of the paving process. The system uses an intelligent temperature scanner over the entire paving width of up to eight metres. The measurement width can be set individually.

With up to 31 measurement points, the scanner achieves an accuracy of plus or minus 2°C at typical asphalt temperatures with the temperature profile being displayed in real-time. As a result, the operator can react at any time if irregularities occur.

In addition, the profile is stored with the GPS position data and transferred to a USB stick. In conjunction with the PAVE Project Manager software, the contractor can evaluate and document the data in the office. Alternatively, the data can be sent via GSM to a server, where it can be called up at any time with a web application.

With optimum composition of both asphalt material and process flow being priorities in the road construction process, the new

The MOBA PAVE-IR system features a high-speed scanner to monitor the temperature during asphalt paving and document it for the entire project. As a result, contractors can optimise their processes and verify the quality of the paving process. The system uses an intelligent temperature scanner over the entire paving width of up to eight metres. The measurement width can be set individually.

With up to 31 measurement points, the scanner achieves an accuracy of plus or minus 2°C at typical asphalt temperatures with the temperature profile being displayed in real-time. As a result, the operator can react at any time if irregularities occur.

In addition, the profile is stored with the GPS position data and transferred to a USB stick. In conjunction with the PAVE Project Manager software, the contractor can evaluate and document the data in the office. Alternatively, the data can be sent via GSM to a server, where it can be called up at any time with a web application.

Stand: A3.227/326

%$Linker: