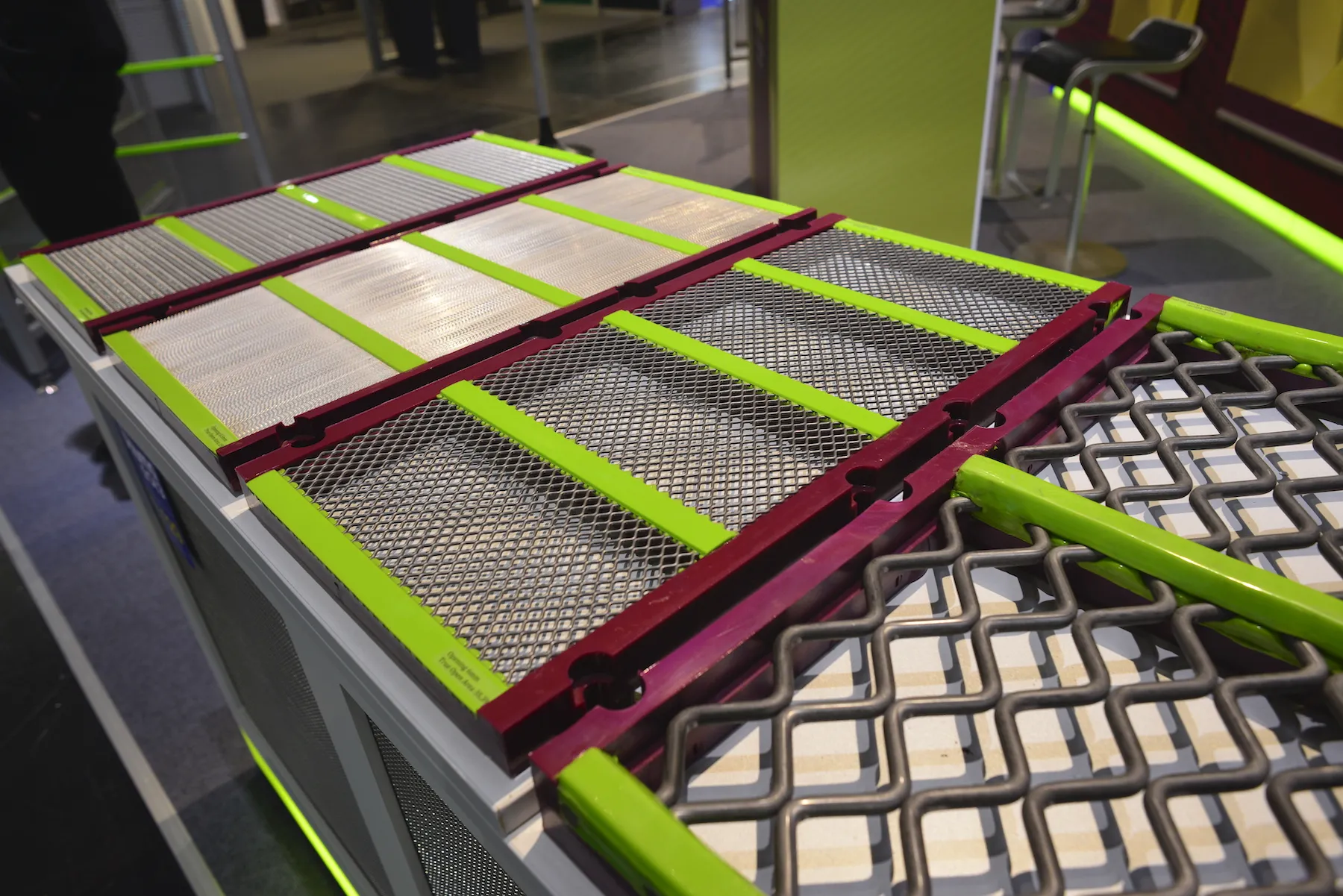

McCloskey International says it is continuing its expansion in 2013 by increasing its bauma presence with indoor and outdoor spaces to showcase new features and product enhancements to its line of crushers, screeners, trommels and stackers. Screeners to be showcased include the S80 and R105, offering the well-established conventional fine material screen S Range and the scalping R Range with 2.5m transport widths. Crushers on display include the bogie-ready J44 jaw crusher; the bogie ready C38 cone as well

January 6, 2017

Read time: 2 mins

Screeners to be showcased include the S80 and R105, offering the well-established conventional fine material screen S Range and the scalping R Range with 2.5m transport widths.

Crushers on display include the bogie-ready J44 jaw crusher; the bogie ready C38 cone as well as the bogie ready I44R, introduced last year and combining crushing, screening and recirculating.

McCloskey International says the new bogie-ready feature on all three crushing models means that customers can attach a bogie unit to each machine, eliminating the requirement for a trailer.

“The same four-axle bogie unit which will also be on display will be suitable for all three models to achieve full TUV road compliance,” says McCloskey, whose new improved TS4065 tracked stacker has a 1m wide belt, 20m long.

McCloskey says in 2012 it 60% growth overall; a 30% increase in workforce and the addition of over 12,635m² in square footage to its plants in Canada and Northern Ireland over the past year.

Stand: B2.125

Stand: FGN.N722/4

%$Linker: