For the first time, a construction machine has been awarded the AGR seal of approval by the Aktion Gesunder Rücken e.V. An independent test commission of experts from various medical fields examined Bomag’s latest generation of pivot-steered tandem rollers according to strict criteria before awarding the operating concept and cabin design of the BW 154 AP-5 and BW 174 AP-5 the seal. Bomag is delighted that its consistent innovations in ergonomics, safety and comfort in the “construction machine workplace” have been independently acknowledged in this way. The quality seal aims to provide reliable guidance for investments in back- friendly solutions in all areas of life.

“No one sitting on a construction machine for several hours a day in their job wants to do without the same high level of comfort as in their car,” explains Tim Eisfeld, head of product management for the asphalt segment at Bomag. “More experienced machine operators in particular also have a heightened awareness of health, especially when it comes to the strain on their own backs in their daily work routine. That's why a modern construction machine must enable the driver to perform the work in a focused, safe manner and without any health restrictions in the long term. But are our solutions at Bomag really as good as we think? This called for independent expertise. We were therefore happy to undergo the extremely thorough and meticulous examination by the experts from Aktion Gesunder Rücken e.V. – and learned a lot in the process. We are proud to be the first construction machinery manufacturer to be awarded the AGR seal of approval for our new pivot-steered tandem rollers. At the same time, the highly recognised seal of quality is, of course, an obligation and incentive for us to constantly think ahead in terms of ergonomics, safety and comfort in order to meet the growing demands and expectations of our machines’ users.”

“No one sitting on a construction machine for several hours a day in their job wants to do without the same high level of comfort as in their car,” explains Tim Eisfeld, head of product management for the asphalt segment at Bomag. “More experienced machine operators in particular also have a heightened awareness of health, especially when it comes to the strain on their own backs in their daily work routine. That's why a modern construction machine must enable the driver to perform the work in a focused, safe manner and without any health restrictions in the long term. But are our solutions at Bomag really as good as we think? This called for independent expertise. We were therefore happy to undergo the extremely thorough and meticulous examination by the experts from Aktion Gesunder Rücken e.V. – and learned a lot in the process. We are proud to be the first construction machinery manufacturer to be awarded the AGR seal of approval for our new pivot-steered tandem rollers. At the same time, the highly recognised seal of quality is, of course, an obligation and incentive for us to constantly think ahead in terms of ergonomics, safety and comfort in order to meet the growing demands and expectations of our machines’ users.”

Sophisticated cab design down to the last detail

Sophisticated cab design down to the last detail

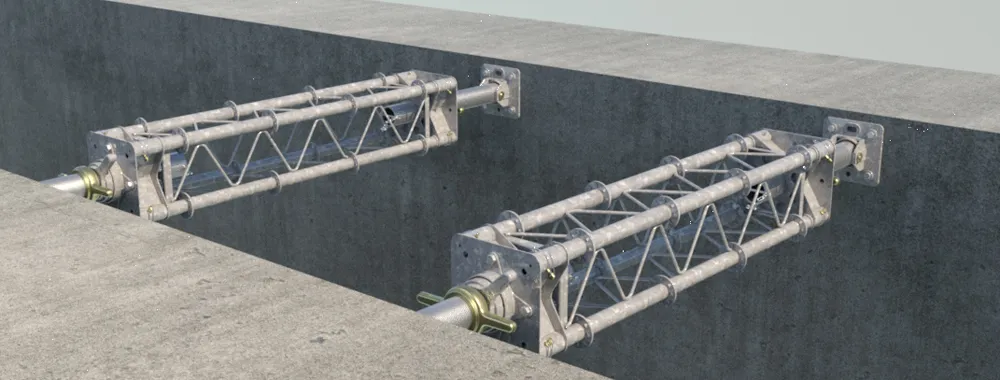

Back-friendly work starts with getting on and off the machine: among other features, the BW 154 AP-5 and BW 174 AP-5 pivot-steered tandem rollers have two extended handholds, three sufficiently deep, non-slip steps and an increased door opening height. This makes climbing on and off safely and upright without slipping or hitting your head easy, even several times a day.

In the cab itself, the ergonomics of the driver's seat are crucial for comfort and the impact on the back. Individual seat adjustments allow the driver to find an upright and comfortable sitting position. The driver’s seat can be adjusted to the individual body weight and the backrest can be reclined. When reversing, the seat can be conveniently rotated 260° via a switch so that the travel position can always be adjusted to the direction of travel.

In addition, there are numerous options for adapting the working conditions in the cab to the needs of the roller operator. One option is an air-cushioned comfort seat with electronic weight adjustment and active seat ventilation and heating. Another is electrically adjustable and heatable outside mirrors and air conditioning. These useful functions help the driver confidently master a stressful working day on the construction site from the machine cockpit – back-friendly, fatigue-free and safe.

In addition, there are numerous options for adapting the working conditions in the cab to the needs of the roller operator. One option is an air-cushioned comfort seat with electronic weight adjustment and active seat ventilation and heating. Another is electrically adjustable and heatable outside mirrors and air conditioning. These useful functions help the driver confidently master a stressful working day on the construction site from the machine cockpit – back-friendly, fatigue-free and safe.

Ease of operation for greater safety

The button for unlocking the seat is within easy reach of the steering wheel. This means the driver can change the seating position without even having to take a hand off the steering wheel. In addition, the seat’s lateral sliding capability provides an optimal view of the outer edges of the roller and the ground. If required, the windows can also be opened and locked separately on the right and left to allow an even better view of the side areas. The cab has large glass surfaces that extend all the way to the floor in key areas for optimal visibility. A ventilation system not only maintains a good working climate but also prevents the windows from misting up, thus ensuring a clear view.

As with a modern passenger car, the word ‘cockpit’ today applies much more to anything that makes it easier for the driver to operate the machine. This also applies to myCOCKPIT in Bomag’s tandem rollers: the customisable touchscreen display allows the driver to preset

As with a modern passenger car, the word ‘cockpit’ today applies much more to anything that makes it easier for the driver to operate the machine. This also applies to myCOCKPIT in Bomag’s tandem rollers: the customisable touchscreen display allows the driver to preset

machine and work functions. All functions that are frequently needed during the work process are also integrated into the seat’s armrest. A joystick for the right hand, a steering wheel for the left – this enables relaxed operation of the machine at any time via the ergonomically shaped controls.

Content produced in association with Bomag