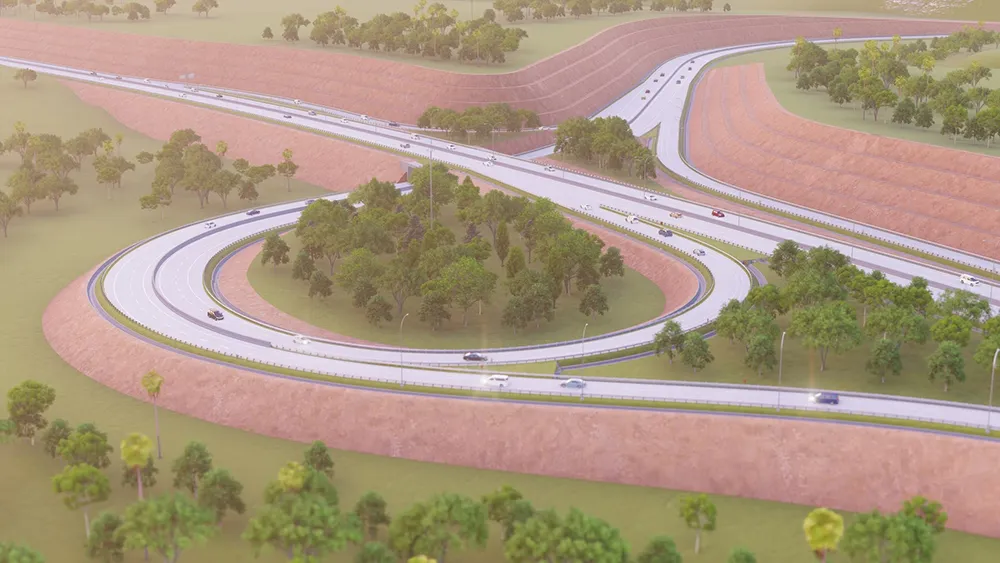

To relieve the congestion, construction has been underway on the Förbifart Stockholm - the Stockholm Bypass.

This is also a first for the Swedish Doka team – a project set up using BIM, Building Information Modelling, the digital representation of physical and functional characteristics of a structure.

Doka’s SL-1 all-round model structure was used to create an SL-1 “model Stockholm bypass” structure because the tunnels were circular, like ones for underground railways. The team, led by Håkan Bratt, Doka’s project manager, adjusted the system so the local contractor Comsa received an economical rental solution to implement a tunnel format of this kind without complications.

Wheels and winches provide the necessary mobility for the systems, while an onsite service for precise cutting of wooden formwork beams shortens working distances. Instead of keeping two or three spares of each of the parts, their use is timed so that the construction company can manage with less material without experiencing shortages.

For safety, the Edge protection system XP was chosen. "It is user-friendly and can be used universally for all edge protection needs," explained Lukas Palme, group leader for engineering at Doka Sweden.

As well as the two circular tunnels, including entrances and exits, the work includes two 20m-long routes in rocky terrain as well as a pair of trough structures, the expansion of existing infrastructure and numerous stabilisation measures along the route.

“We surprised Comsa with a 3D model on our own initiative,” said Jan Radlbauer, Doka’s head of engineering for Europe. The more complex the geometry, the more important it is to fully map the building space. Doka also drew the underlying model so that the customer could visualise it.

All employees are connected via their mobile devices and, therefore, are always up-to-date when construction data changes or an update is available. Problems are evaluated more quickly and errors rectified more easily than if everyone had to be individually briefed on the vast construction site.

BIM 360 and the design software Revit helped visualise the challenging tunnel geometries down to the smallest detail, especially the formwork constructions. When different countries are involved, data and sketches help everyone understand what's going on. Participation such as this assures understanding by everyone about what their tasks are and they can discuss all manner of issues surrounding the tunnel construction.

“The BIM model helped us plan the works before execution since it gave us the unique ability to see how everything would look in reality. This is very helpful when it comes to production and crane planning, especially when you combine the knowledge of a professional formwork supplier like Doka, an experienced subcontractor and our own expertise,” said Martin Klimt, block manager for concrete/formwork at Comsa.

As things stand, the six sections involving Doka will be handed over to the client on time and within budget after roughly five years of planning and construction. When the junctions between Kungens Kurva (King’s Curve) in the south and Häggvik in the north are approved for traffic- likely in 2025 - the Stockholm Bypass will be one of the three longest road tunnels in the world, helping to ensure that Stockholm continues to be one of the best places to live.

DOKA PRODUCTS USED

- Framed formwork Frami and Framax

- Large-area formwork Top 50

- Heavy-duty supporting system SL-1

- Load-bearing tower

- Timber-beam floor formwork Dokaflex

- Edge protection system XP

- Services provided: planning, BIM, onsite service, pre-assembly service