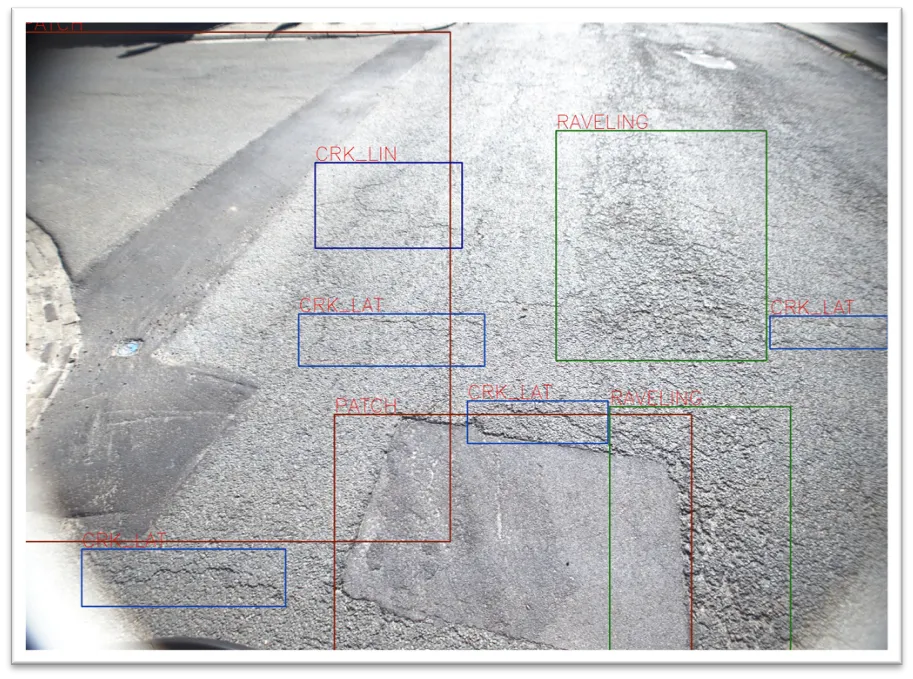

XenomatiX has added to its road scanning solution the capability to detect, with 95% accuracy, up to 14 types of road cracks. The company says this makes its road scanning services a full comprehensive solution for road inspection.

With one lidar system and camera installed on any vehicle, XenomatiX already measures and collects, in one go, data on the condition of the pavement. This includes evenness indexes such as IRI and rutting, road markings and potholes.

Now, an additional 14 types of road distress can be measured, including different types of cracks, bleeding and raveling. This facilitates an efficient road monitoring process allowing road owners to increase their productivity, by saving time in the field and in budget.

The company has developed two key solid-state lidar products to enhance safer roads, the XenoTrack, road lidar for cost-effective road management and XenoLidar for enabling autonomous vehicle. In the future of autonomous cars, XenomatiX inspires to achieve a fully digitised road system where every vehicle in the road is continuously collecting road condition data and feeding this back to city councils who can address the infrastructure needs and challenges for safer roads.

XenomatiX, based in the Belgian city of Leuven, designs solid state lidars based on a multi-beam laser concept and scalable semiconductor technology with different product lines to serve different industries and applications. The company’s products have been recognised by international competition programmes such as the IRF GRAA award and the CES Innovation Award.

XenomatiX employs around 50 people in Belgium, Germany, US and China and has a global distribution network.