The Crossflow wind turbine is said to address challenges such as noise, vibration and size, opening up a range of applications for the highways sector.

The Crossflow turbine is a scalable Transverse Axis Wind Turbine. The small, efficient and reliable turbine incorporates a patented shield designed in collaboration with Swansea University through extensive Computational Fluid Dynamics simulations. This novel design increases airflow, delivering optimum lift and drag performance across a wide range of wind speeds, boosting its range of duties. In addition, its advanced lightweight blade has optimised aerodynamics for high efficiency in generating power and to ensure it self-starts at low wind speeds.

The turbine’s low rotational speed generates minimal noise and vibrations. The turbine design is bird and bat friendly, addressing planning concerns, even in ecologically sensitive sites.

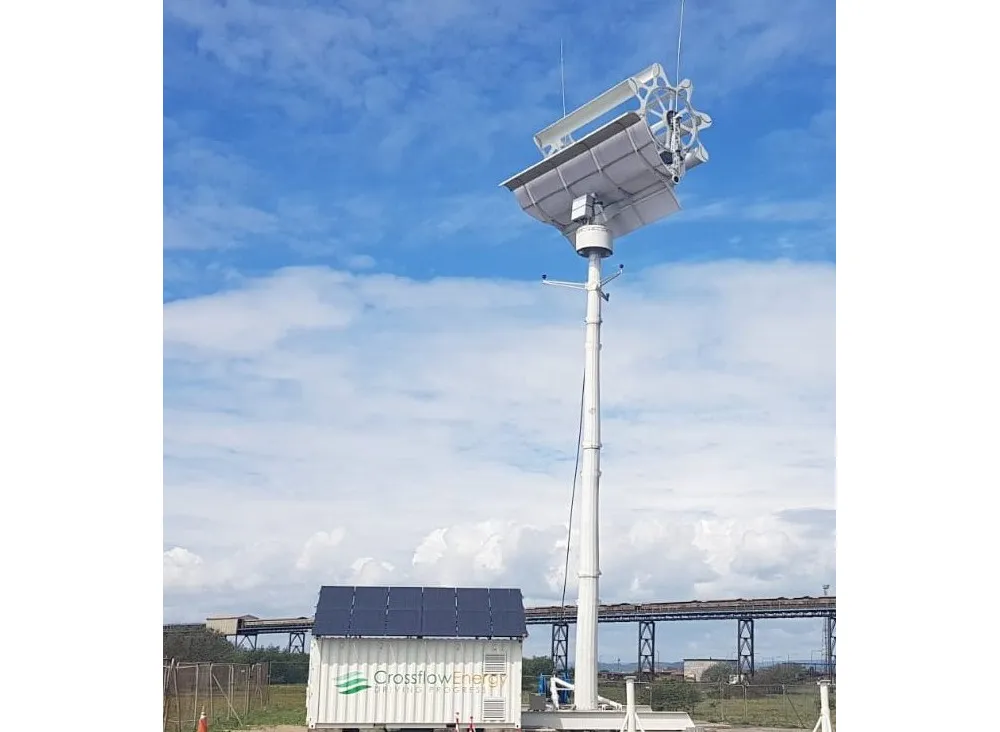

It can be deployed as a standalone entity or combined with solar and battery technology in either new build or retrofit applications.