A fleet of compact and zero tailswing New Holland excavators has been deployed to assist with motorway crash barrier replacement work.

February 6, 2012

Read time: 2 mins

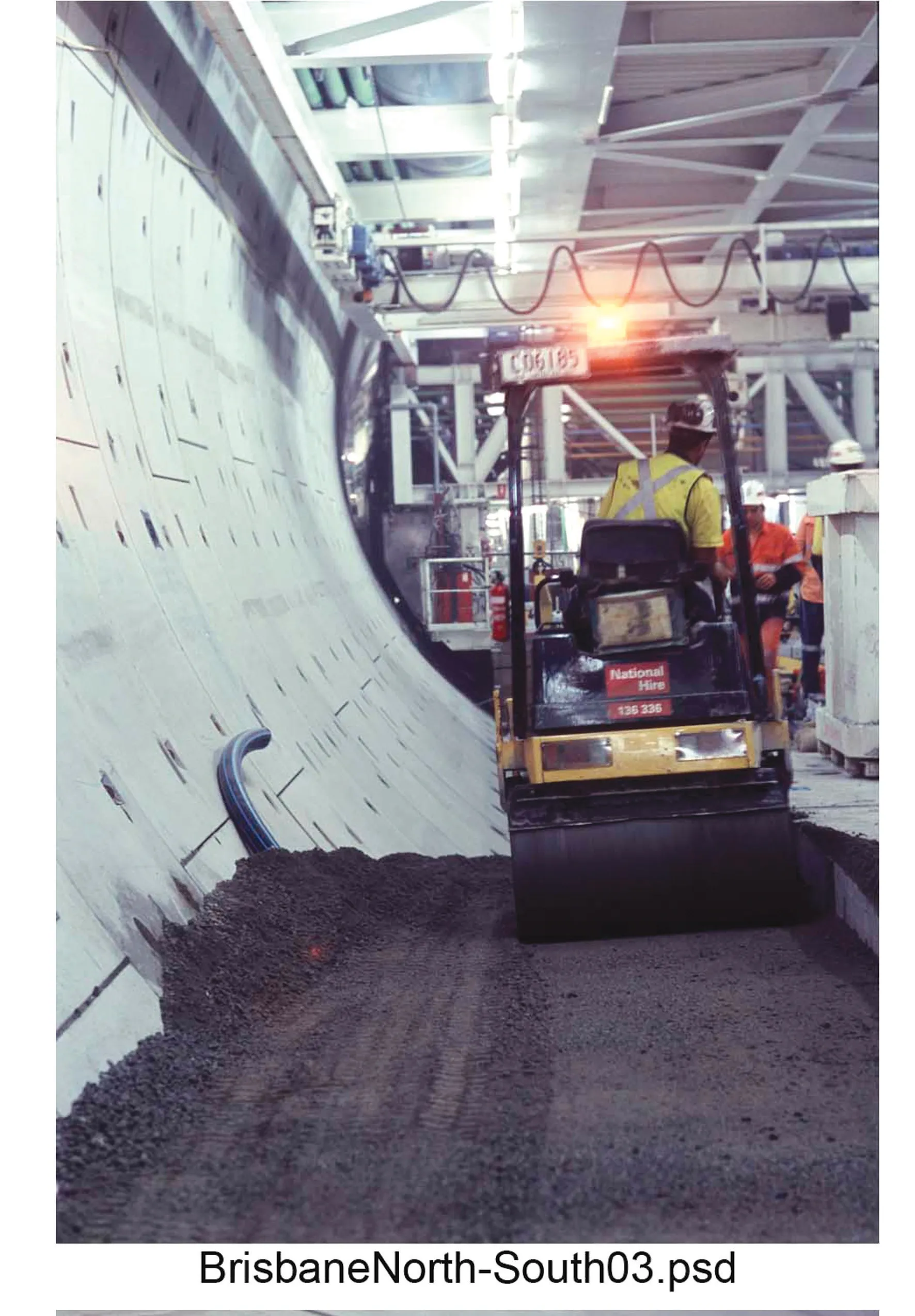

A fleet of compact and zero tailswing 5895 New Holland excavators has been deployed to assist with motorway crash barrier replacement work.

The work is on one of the busiest sections of the M62 in County Yorkshire, northern England, and local civil engineering contractor1147 K Rouse has deployed eight reduced tailswing tracked machines (four E235Bs and four E135Bs) as well two compact radius MH City wheeled excavators between junctions 27 and 28, south of the city of Leeds. The machines are being used to install new drainage prior to the replacement of the existing steel fences with the now mandatory concrete barriers.

With only one lane of each side of the motorway closed during the work, the space to operate in is limited.

While the E235B tracked machines are used in the central reservation itself as primary earthmovers to excavate the drainage channels, and their smaller E135B cousins work predominantly on backfilling, the MH City machines are used to transport and install materials on site. As a result, they frequently work in the closed lane of the motorway.

"Their great advantage in such a confined area is that they are virtually zero tailswing, which is obviously a very important safety feature in this line of work," said Jim McGibbon, the company's plant manager.

It was this combination of safety and productivity that initially persuaded main contractor1146 Balfour Beatty to employ K Rouse on the job. "They became aware of it through cross hire, and saw a distinct advantage of using the City machines along with other compact radius models," said McGibbon.

Now the company has been awarded the contract for similar work between junctions 29 and 30 of the M62 which is due to start shortly.

The work is on one of the busiest sections of the M62 in County Yorkshire, northern England, and local civil engineering contractor

With only one lane of each side of the motorway closed during the work, the space to operate in is limited.

While the E235B tracked machines are used in the central reservation itself as primary earthmovers to excavate the drainage channels, and their smaller E135B cousins work predominantly on backfilling, the MH City machines are used to transport and install materials on site. As a result, they frequently work in the closed lane of the motorway.

"Their great advantage in such a confined area is that they are virtually zero tailswing, which is obviously a very important safety feature in this line of work," said Jim McGibbon, the company's plant manager.

It was this combination of safety and productivity that initially persuaded main contractor

Now the company has been awarded the contract for similar work between junctions 29 and 30 of the M62 which is due to start shortly.