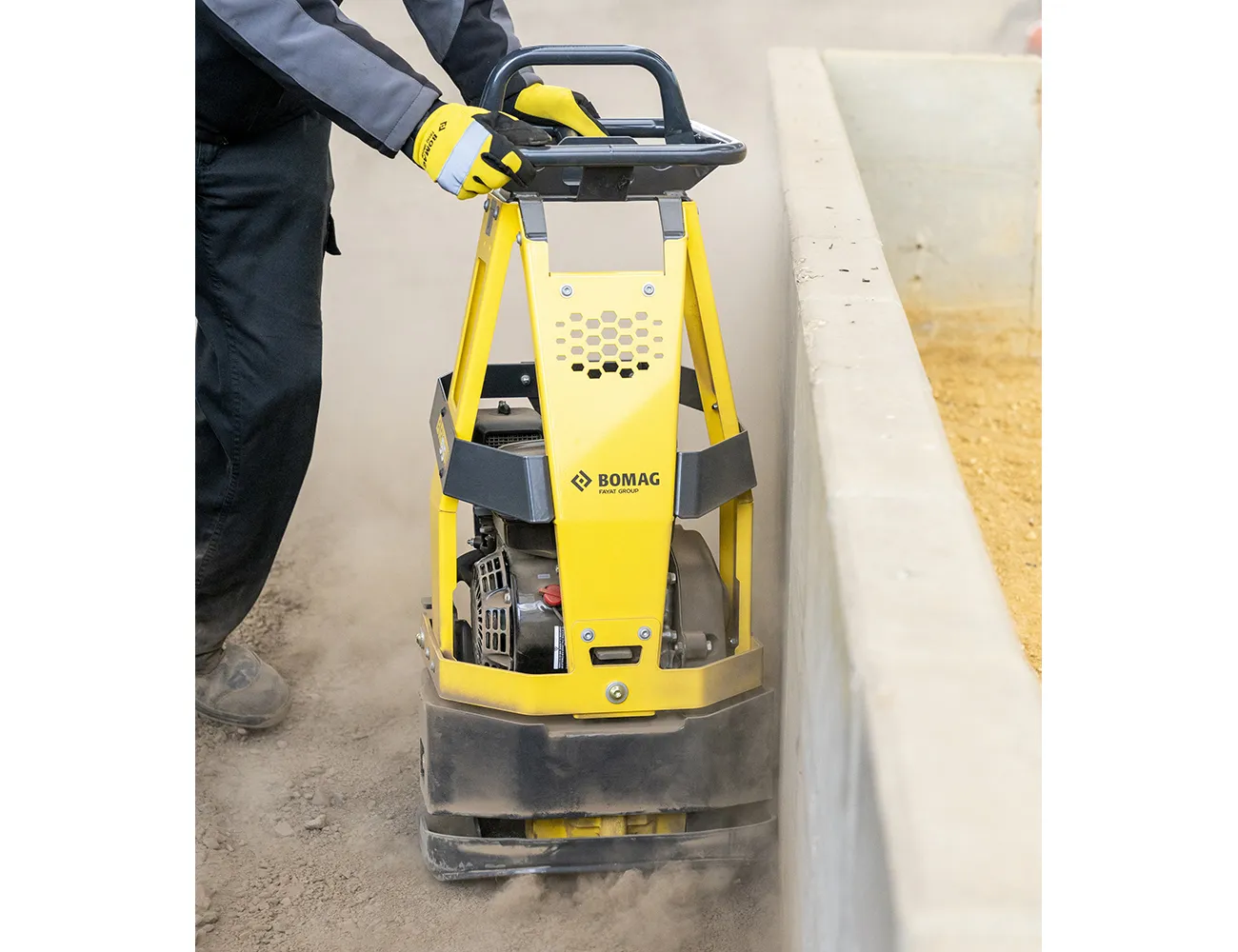

The firm says that the unit is agile and easy to handle and is well-suited to duties in earthworks where flush compaction is required in small spaces, such as close to building walls, posts or in cable and pipe trenches. This is made possible by a square base plate with rounded corners and a slim machine design. The all-round guide handle provides grip for the operator in their grip in any situation, as well as featuring low vibration for fatigue-free working.

The working speed of 30m/min is said to ensure high efficiency. Depending on the material, the fill height in one pass is 250mm. With a lower amplitude than a tamper and a weight of 92kg, the BR 95 is convenient and safe to operate.

The 450mm square base plate with rounded corners allows every side to travel along walls and edges for flush compaction. In addition, the slim design of the column above the base plate, with nothing protruding beyond the base plate, ensures freedom of movement.

The all-round guide handle positioned above the engine enables the operator to guide the machine in any position, like a steering wheel. Changes of direction can be handled under complete control, even in confined environments like a cable trench.

Mechanical vibrations have been minimised, allowing operators to work with the Bomag BR 95 for up to 8 hours. A low centre of gravity makes the machine easy to steer and ensure it has a secure footing.

Key parts are protected against dirt and impact damage, minimising wear in tough working conditions. A side guard helps to ensure that the 3.5kW engine has a long service life. The additional cyclone filter pre-filters the air so that fewer dust particles reach the filter. The V-belt is, of course, completely protected from dirt and dust. The exhaust gases are directed downwards, and the tailpipe has a heat protection plate.