New Holland Construction's Tier IV Interim solutions and the first models with SCR (Selective Catalytic Reduction) technology will be launched along with the new ranges of wheel loaders and crawler excavators, featuring the new technologies.

February 15, 2012

Read time: 2 mins

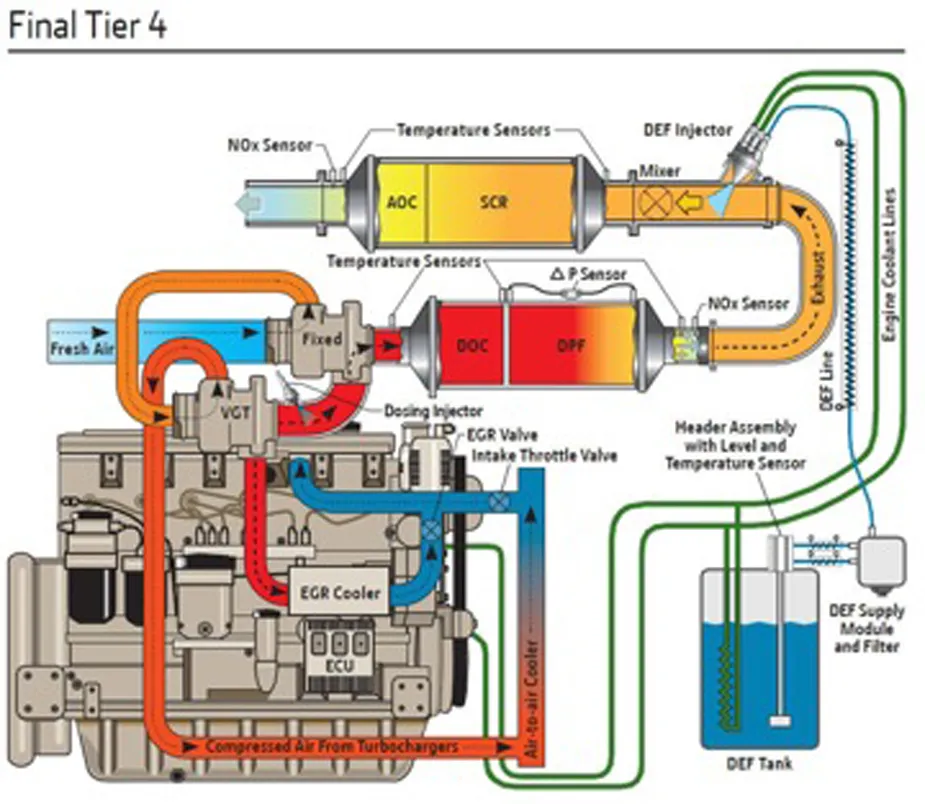

The E305C crawler excavator and the two wheel loader models, the W170C and W190C, all feature New Holland's SCR technology to achieve compliance with Tier IV interim emissions regulations. This after-treatment system breaks down the NOx into nitrogen and water, which occur naturally in the atmosphere, through a chemical reaction with a diesel exhaust fluid (DEF), AdBlue.

The E305C crawler excavator, with SCR technology, has an operating weight of 31.7tonnes and a bucket capacity of 0.6-1.65m3 and offers a 10% increase in productivity in terms of cubic metres/hour and a 10% reduction in fuel consumption in ECO mode compared to the equivalent B Series model.

The new W170C and W190C wheel loaders feature high-pressure common rail engines with the SCR system contributing to achieving 9-17% better fuel economy than the equivalent Series B models.

The B115B and B110BTC backhoe loaders introduce new features that significantly increase fuel efficiency, operator comfort, productivity and durability.

Sister companies Astra and