The introduction of a new backhoe loader line is a major development for Case, Mike Woof reports. Case is introducing its new backhoe loader line-up for the European market, which offers key performance improvements. There are four models being introduced, the 695ST, 590ST, 580ST and 580T, aimed at different market segments and intended to encompass the entire range of customer requirements. This is an important launch for CNH, which has been offering a fully-integrated backhoe loader in its line-up since 1

February 15, 2012

Read time: 4 mins

More compact, more economical to run and more productive, the new machines offer performance benefits over the models they replace. Henrik Starup, vice president of CNH said, "This is one of the most important products for Case and is the first launch of many for the next few months as we're going to update 90% of our range. Of course much of this is driven by Tier 4 but we have a whole list of other improvements." Reduced fuel consumption and emissions are important features of the new models and the firm has also been keen to lower the cost of ownership for the customer. Alain de Nanteuil is product manager for backhoe loaders at Case and said, "We've made a machine that will consume less fuel." Fuel consumption is improved by 10%, which will make a major saving on running costs in Europe where diesel prices are high. Meanwhile front-end performance is boosted by 20% and de Nanteuil said, "We increased the front bucket size by 20% to 1.2m3." When redesigning the backhoe loaders Case also took into account customer feedback, making the backhoe attachment fold into a more compact size that reduces headroom clearance by 300mm to 3.4m. The new backhoe arm also tucks in more closely to the machine while the new curved boom is fabricated and lighter than the cast unit it replaces. However, the digging depth and reach remain the same as with the previous generation machines due to the novel design of the extending dipper. The high performance of the backhoe is of key importance for this machine range and de Nanteuil said, "The backhoe represents 70% of the use of the machine." The new attachment system allows the operator to change tools without having to leave the machine cab and de Nanteuil said, "We are the first manufacturer with an integrated quick coupler on a backhoe loader." The coupler features a cylinder that pushes out the pins and locks the system, which is also able to use existing buckets from earlier generation Case backhoe loaders. To meet UK health and safety requirements for attachment security, operators will have to get out of the cab to place a mechanical retaining pin however. In addition, a hydraulic sideshift will be available shortly as an option for the backhoe attachment.

The top of the range model is the 695ST, which has equal-sized wheels, all-wheel steer and other steering modes, features a higher front end performance and is aimed at the high end of the market. The 590ST and 580ST are both high performing backhoe loaders, with unequal sized wheels and joystick type controls for the backhoe attachment. The 580T is a base model with conventional hydraulic controls that is aimed specifically at customers in the rental market and particularly in the UK.

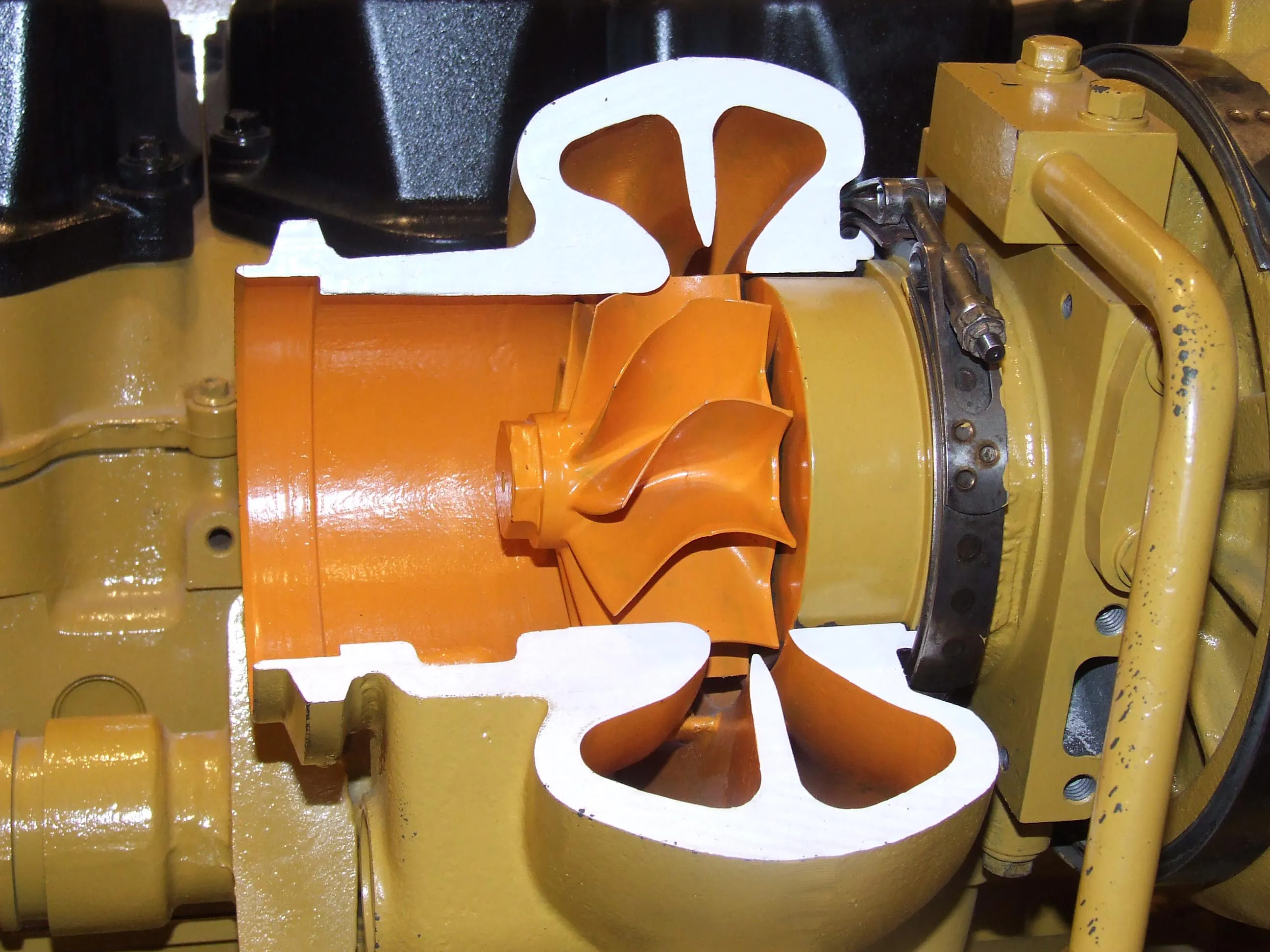

Power for the 580T and 580ST models comes from an FPT diesel rated at 71kW, while the 590ST and 695ST have a more powerful FPT engine rated 82kW. The engines are Stage IIIA/Tier 3 compliant as the Stage IIIB/Tier 4 Interim emission regulations for engines under 130.5kW only come into force from the beginning of 2012. The company does have its engine emissions development programme well on track however and says that a compact, reliable and durable solution will be available for the market next year.

The 580ST, 590ST and 695ST all feature more sophisticated hydraulics than previous generation machines with variable displacement pumps, while the simpler retains the proven hydraulics of the earlier machines. The low noise cab features large windows for maximum visibility as well as additional lighting to allow night working and de Nanteuil added, "We have power steering as standard on all our backhoe loaders." Other improvements include larger diameter wheels at the front of the 590 and 580 models to improve traction, driving and steering characteristics and upgraded transmissions.

The firm is also boosting its dealer network across Europe and Starup said, "We are signing more than 10 new dealers in the next few months." Because of the broad range of machines in the CNH line-up, it is not possible to have a single team at each dealership marketing the large machines as well as the compact equipment, so this is also factored into the equation. Support will be strong for machine buyers and Starup added, "I think Case has always been customer focussed."