With a bucket tipping load of 5,600kg, a stack payload of 3,900kg and an operating weight of 9,150kg, the 8155 model opens up a new size class in the Kramer wheeled loader product portfolio. As with all all-wheel, crab and front-axle steering are available as standard.

“When we look at the wheeled loader market, we see that the performance class of the 1.5m³ loaders has experienced a significant upturn in the past two years. With our new flagship in the Kramer wheeled loader portfolio, we serve this segment,” explains Karl Friedrich Hauri, managing director of Kramer.

The 8155 can be used for material transport on large construction sites as well as for loading and unloading heavy transport chains and carriers. But the new wheeled loader is also used for municipal winter road clearance services – especially in surface clearing and road clearance.

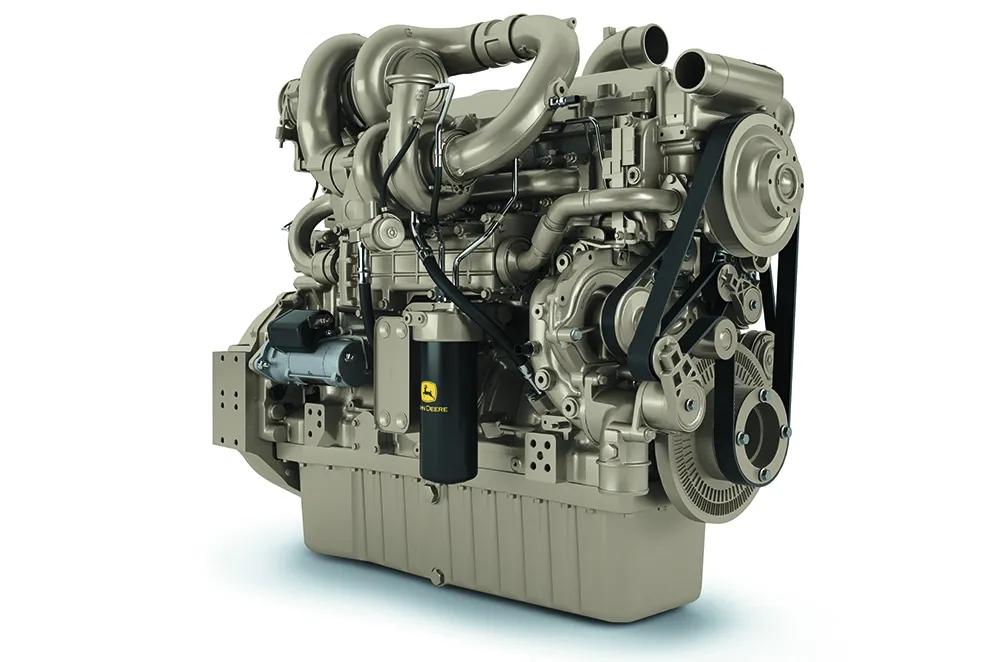

The new Kramer flagship is powered by a 100kW

From 0-40kph it can be driven without shifting and thus without loss of thrust and tractive forces. In typical working situations, such as handling work in the Y-cycle, there is a high demand for constant thrust and traction forces at low travel speeds. The ecospeedPRO gear unit exactly meets these requirements.

The ecospeedPRO travel drive is equipped with the intelligent Smart Driving motor speed reduction as standard. This adapts the engine speed at constant speed optimally to the driving requirements.

When the maximum speed is reached, this results in reduced noise, lower fuel consumption and reduced stress on the individual components. With ecospeedPRO, the engine speed can be reduced to 1,550rpm at maximum travel speed.