Cumbria-based Hyundai dealer Taylor & Braithwaite has sold the first Hyundai R125LCR-9A in the UK to Stephen Smith Plant Hire, also based in the county of Cumbria.

Stephen Smith is a one-man-one-machine operator who works all-around the Cumbrian region.

This new weight class machine was first launched in 2014 at the Hillhead exhibition in the UK. Smith said he had to wait almost a year because the machine had not been available yet in the UK.

June 9, 2015

Read time: 3 mins

Cumbria-based 236 Hyundai dealer Taylor & Braithwaite has sold the first Hyundai R125LCR-9A in the UK to Stephen Smith Plant Hire, also based in the county of Cumbria.

Stephen Smith is a one-man-one-machine operator who works all-around the Cumbrian region.

This new weight class machine was first launched in 2014 at the5894 Hillhead exhibition in the UK. Smith said he had to wait almost a year because the machine had not been available yet in the UK.

“I did consider the R145LCR-9A, a 14.5tonne machine, but it was a bit too big for what I wanted so I decided to hold out for the smaller 12.5tonne machine,” said Smith “The R125 machine is perfect for working on smaller sites where it’s difficult to manoeuvre. The short radius swung it for me.”

Taylor & Braithwaite’s sales director Ian Burton said the new Hyundai R125LCR-9A fills a gap in the Hyundai range. The midi short tail swing crawler excavator sits between the 8tonne R80LC-9A, 8 tonne and the 14tonne R140LC-9A, machines. The boom is not offset, which allows the machine to operate in tight spots.

The midi excavator offers arm digging force to 60,212N and a bucket digging force of 90,221N. The machine has an operating weight of 12.5tonnes and a maximum digging depth of 5.06m.

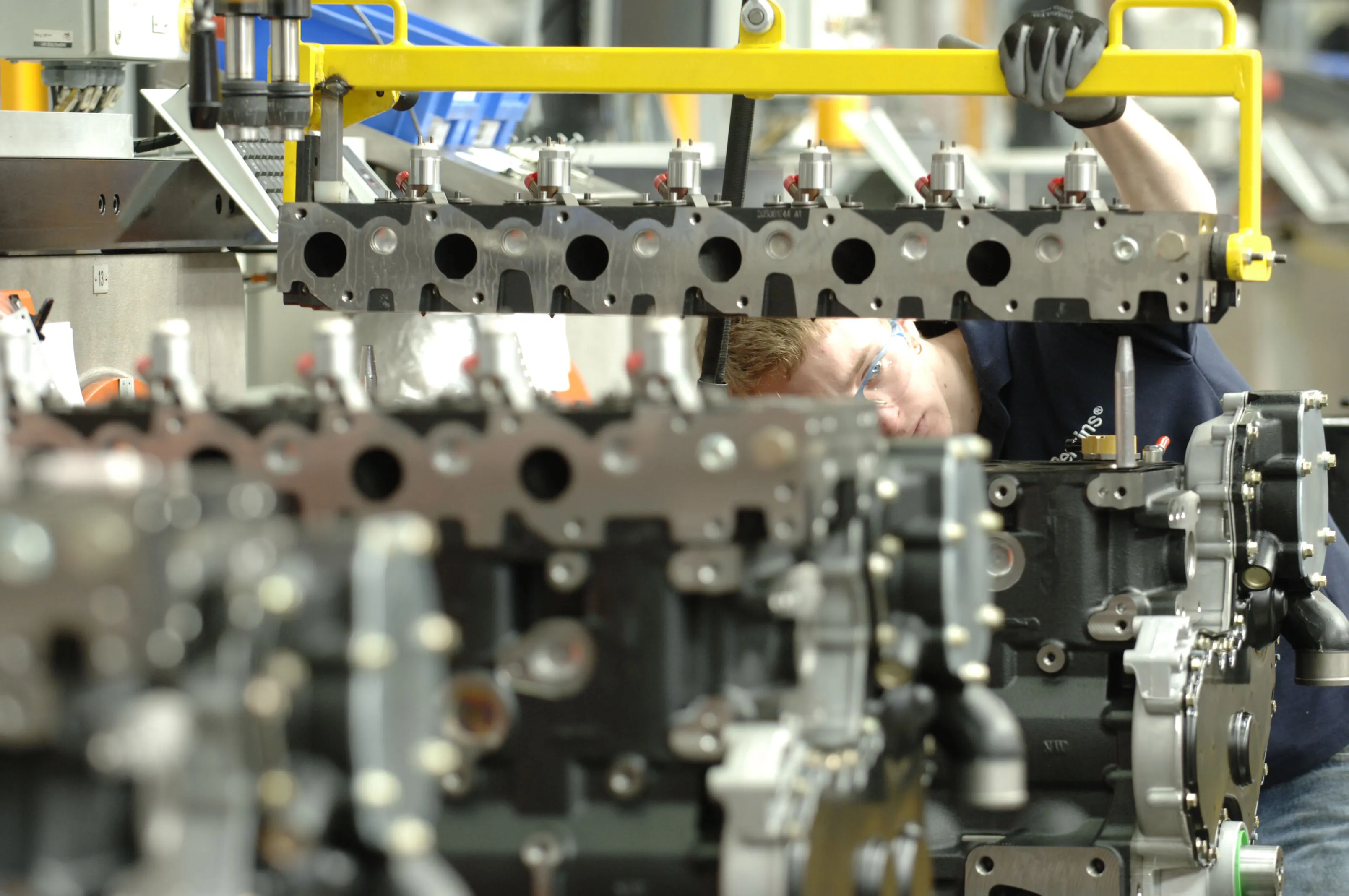

The R125LCR-9A cabin structure has been fitted with stronger but slimmer tubing for added safety and improved visibility. Low-stress, high strength steel is integrally welded to form a stronger, more durable upper and lower frame. The R125LCR-9A is fitted with a Tier 4 interim/Stage IIIB299 Perkins 1204E engine. Electronically controlled fuel injection and diagnostic capabilities add to the engine's efficiency and serviceability.

The machine is also fitted with Hi-Mate, a remote management system developed by Hyundai Heavy Industries. Through its GPS-satellite powered technology, with one press of the button, users are able to remotely evaluate machine performance, access diagnostic information and verify machine locations. It’s even possible to program a virtual geo-fence to prevent the machine from leaving a specific area.

Hyundai says it’s -9A series excavators have a 5% fuel savings in comparison to previous models, thanks to the variable speed remote fan, two-stage auto decel system and the new economy mode.

Stephen Smith is a one-man-one-machine operator who works all-around the Cumbrian region.

This new weight class machine was first launched in 2014 at the

“I did consider the R145LCR-9A, a 14.5tonne machine, but it was a bit too big for what I wanted so I decided to hold out for the smaller 12.5tonne machine,” said Smith “The R125 machine is perfect for working on smaller sites where it’s difficult to manoeuvre. The short radius swung it for me.”

Taylor & Braithwaite’s sales director Ian Burton said the new Hyundai R125LCR-9A fills a gap in the Hyundai range. The midi short tail swing crawler excavator sits between the 8tonne R80LC-9A, 8 tonne and the 14tonne R140LC-9A, machines. The boom is not offset, which allows the machine to operate in tight spots.

The midi excavator offers arm digging force to 60,212N and a bucket digging force of 90,221N. The machine has an operating weight of 12.5tonnes and a maximum digging depth of 5.06m.

The R125LCR-9A cabin structure has been fitted with stronger but slimmer tubing for added safety and improved visibility. Low-stress, high strength steel is integrally welded to form a stronger, more durable upper and lower frame. The R125LCR-9A is fitted with a Tier 4 interim/Stage IIIB

The machine is also fitted with Hi-Mate, a remote management system developed by Hyundai Heavy Industries. Through its GPS-satellite powered technology, with one press of the button, users are able to remotely evaluate machine performance, access diagnostic information and verify machine locations. It’s even possible to program a virtual geo-fence to prevent the machine from leaving a specific area.

Hyundai says it’s -9A series excavators have a 5% fuel savings in comparison to previous models, thanks to the variable speed remote fan, two-stage auto decel system and the new economy mode.