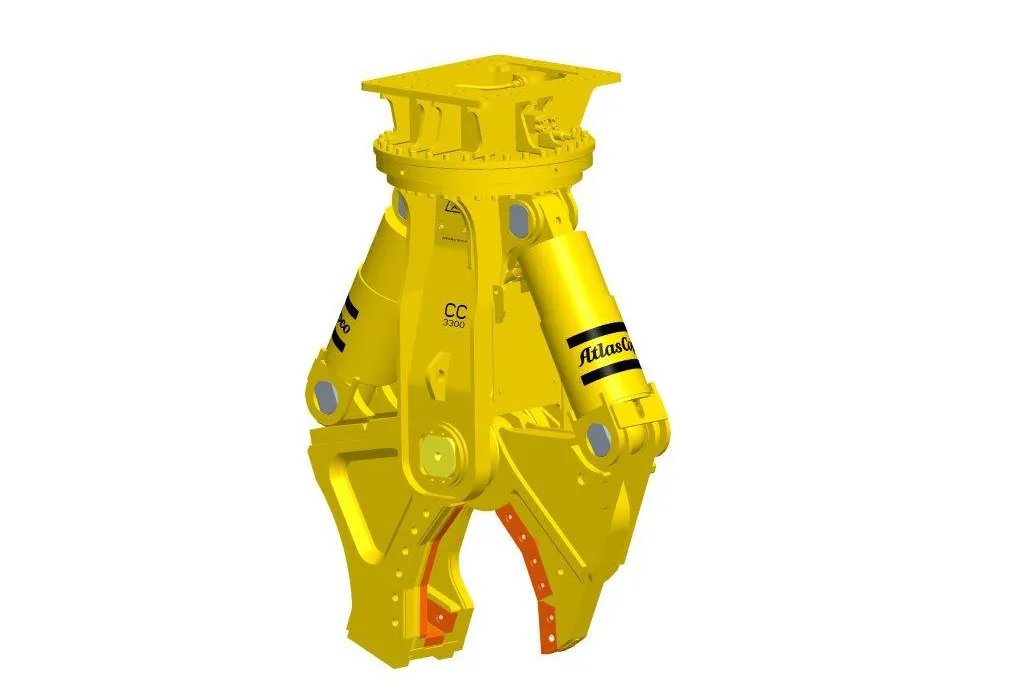

Atlas Copco claims the angled shape of its two new hydraulic bulk pulverisers, available for carriers of 18 to 35tonnes, make them ideal for secondary demolition of reinforced concrete. The broad jaw of the BP 2050, BP 2050 R, BP 3050 and BP 3050 R machines ease the feeding in of material on the ground which, Atlas Copco (AC) claim, speeds up work and enables cleaner separation of rebar and concrete prior to their reduction into grain sizes suitable for crushing or use as back ll.

April 20, 2012

Read time: 1 min

The broad jaw of the BP 2050, BP 2050 R, BP 3050 and BP 3050 R machines ease the feeding in of material on the ground which, Atlas Copco (AC) claim, speeds up work and enables cleaner separation of rebar and concrete prior to their reduction into grain sizes suitable for crushing or use as back ll.

An optional hydraulic rotation device will, according to AC, enable the new pulverisers to be used for e cient demolition of ceilings and walls.