Doosan Construction Equipment is launching its high-performance DX210W-5 wheeled excavator. This 21 tonne wheeled excavator is Stage IV compliant and also features a new styling scheme common to all new generation machines from Doosan.

The new DX210W-5 offers improved comfort and controllability, as well as better efficiency and uptime. Increased power, durability and high manoeuvrability are all key feature of the machine.

To help optimise uptime, all Doosan Stage IV excavators weighing more than

June 9, 2015

Read time: 2 mins

Doosan Construction Equipment is launching its high-performance DX210W-5 wheeled excavator. This 21 tonne wheeled excavator is Stage IV compliant and also features a new styling scheme common to all new generation machines from Doosan.

The new DX210W-5 offers improved comfort and controllability, as well as better efficiency and uptime. Increased power, durability and high manoeuvrability are all key feature of the machine.

To help optimise uptime, all695 Doosan Stage IV excavators weighing more than 14tonnes benefit from the firm’s sophisticated CoreTMS fleet management system, which is fitted as standard. This system has been designed specifically for the Doosan range and is a new tool providing comprehensive information about machine performance in a dual mode (satellite, GSM). Because the software in the CoreTMS system has been upgraded to communicate directly with the EPOS system on a Doosan excavator, it provides high level information about equipment to help customers work more effectively. Also available for retro-fitting in a kit form, the system is supplied with a free three-year subscription in new W-5 wheeled excavators.

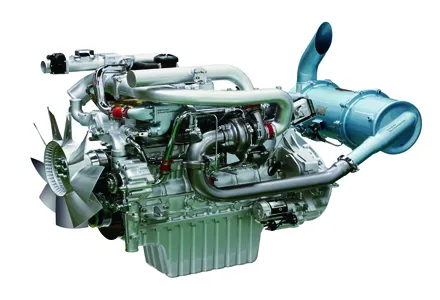

The DX210W-5 excavator is powered by the well-proven six-cylinder, turbocharged Doosan DL06P water-cooled diesel providing 141.2kW, a 17% increase in power over the previous generation machine. The DL06P engine meets the Stage IV emissions regulations without the need for a diesel particulate filter (DPF), through the use of cooled exhaust gas recirculation (EGR) and selective catalyst reduction (SCR) after-treatment technologies.

As well as the DL06P engine, new innovative and exclusive features have been introduced that reduce fuel consumption by an average of 10%. Among these features is the new Trip Meter Setting screen which allows operators to check fuel consumption daily (or over a desired period) directly from the control panel. Further fuel efficiency results from the electric fan clutch on the DX210W-5 excavator which drives the cooling fan at optimum speed.

The DX210W-5 has 14% more torque and the new Posicon hydraulic system, which offers a 3% increase in hydraulic capacity. The 900kg weight increase and the greater machine width boost front lifting capacity by 4-8% (attachment down/up).

Other improvements include a new cab design with increased space for the operator, ergonomic controls and improved visibility.

The new DX210W-5 offers improved comfort and controllability, as well as better efficiency and uptime. Increased power, durability and high manoeuvrability are all key feature of the machine.

To help optimise uptime, all

The DX210W-5 excavator is powered by the well-proven six-cylinder, turbocharged Doosan DL06P water-cooled diesel providing 141.2kW, a 17% increase in power over the previous generation machine. The DL06P engine meets the Stage IV emissions regulations without the need for a diesel particulate filter (DPF), through the use of cooled exhaust gas recirculation (EGR) and selective catalyst reduction (SCR) after-treatment technologies.

As well as the DL06P engine, new innovative and exclusive features have been introduced that reduce fuel consumption by an average of 10%. Among these features is the new Trip Meter Setting screen which allows operators to check fuel consumption daily (or over a desired period) directly from the control panel. Further fuel efficiency results from the electric fan clutch on the DX210W-5 excavator which drives the cooling fan at optimum speed.

The DX210W-5 has 14% more torque and the new Posicon hydraulic system, which offers a 3% increase in hydraulic capacity. The 900kg weight increase and the greater machine width boost front lifting capacity by 4-8% (attachment down/up).

Other improvements include a new cab design with increased space for the operator, ergonomic controls and improved visibility.