RoadBotics is announcing the addition of Image Logger to its growing suite of products to help communities digitise assets such as roads, sidewalks and trails.

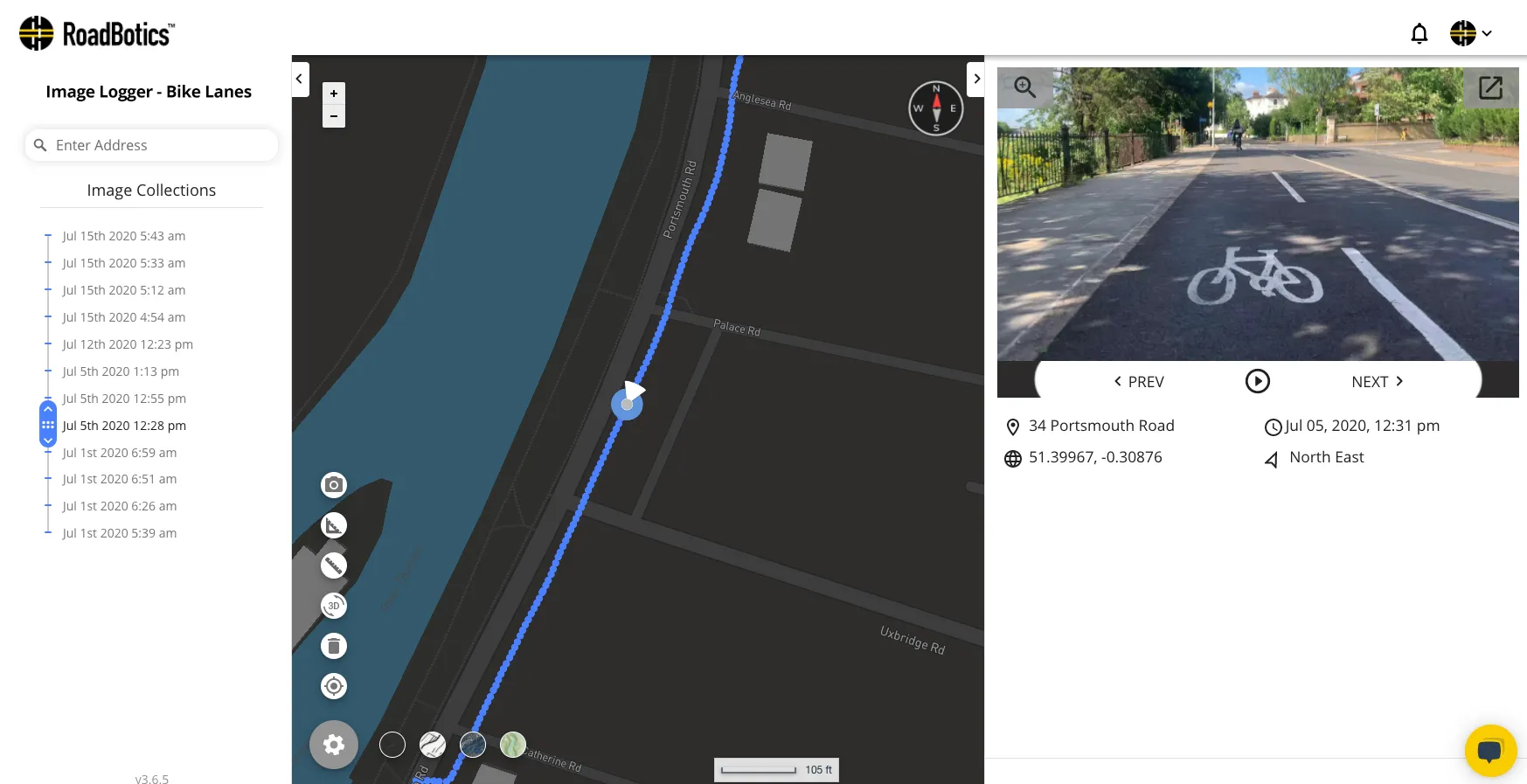

The company, based in Pittsburgh in the US state of Pennsylvania, said the technology places time-stamped geo-spatial image data on a GIS-enabled map. The result allows local authorities to view all public assets on one platform - from a desk or out in the field.

“The Image Logger is a great addition to our existing products and tools for road and infrastructure management,” said Matt Lucas, head of product at Roadbotics. “It helps our clients to better administer their assets while saving valuable resources.”

RoadBotics - known for automated pavement assessments using a smartphone for data collection –users can collect data on roads and adjacent assets such as signage and public right of ways including sidewalks, bike trails and walking paths. Whether collected monthly, seasonally or before and after maintenance projects, up-to-date data is invaluable for asset management.

The Image Logger was released in early June as the first product for the company’s new RoadWay Operating System, a cloud-based online platform. RoadWay OS helps governments manage and administer their public infrastructure asset data in one central location. “Image Logger accomplishes that objective by the ease of use and breadth of data available,” said Benjamin Schmidt, president and co-founder of RoadBotics.

Roadway OS is also available to outside consultants and professionals who help governments maintain infrastructure, whether this is managing tactical day-to-day operations or enhancing strategic planning.