According to the Swedish manufacturer, the EC233, with a break torque of 340kNm, will be the market's most powerful tiltrotator for excavators between 24-33tonnes.

The EC233 replaces Engcon’s EC30, which has been in production since the mid 1990's, notes Robert Hunt, managing director of Engcon UK.

The product development cycle was focused on destructive tests where both mountings and connectors were exposed to extreme overload in laboratory environments. Testing then continued on large excavators in the field.

Fredrik Jonsson, development manager at Engcon, says that they start by putting the test products under huge stress in a powerful hydraulic rig where the unit is overloaded in a controlled environment. “It gives us a clear picture of where any structural flaws may exist,” he said.

Meanwhile, Engcon and

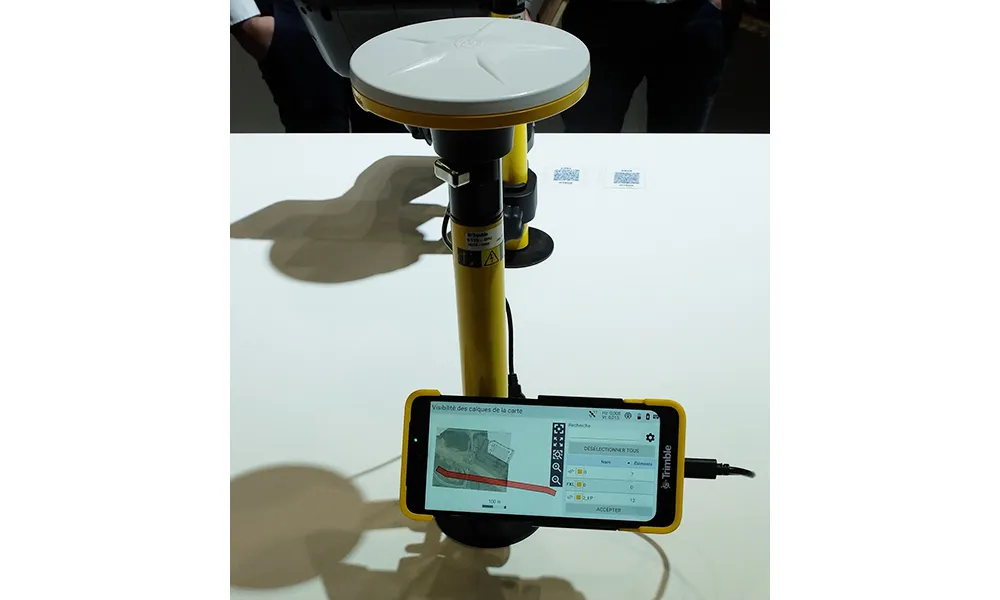

In recent years, customers have been able to use Engcon’s Positioning System (ePS) together with Earthworks, Trimble’s Grade Control technology platform. The driver can see the exact position of the bucket shown on the screen in the excavator cabin.

Now the two companies are taking the next step in collaboration, combining Engcon’s automatic tilt function in combination with Trimble’s Earthworks excavation system, which includes GS5x0 sensors and software version v1.7.0. or newer, to allow guidance and automated control.

Another powerful customer benefit is that Engcon's DC2 control system will be made available for download directly in Trimble’s Android display via Trimble’s App Central. This means that users have access to remote support directly through the large Trimble display and the digging system's internet connection. The DC2 operates completely independently from the customers' phone type.